What is the purpose of a Dual Head Welding Gun?

In the fields of air conditioning and refrigeration repair, small appliance maintenance, and precision hardware processing, the choice of tools often determines the efficiency and quality of work.

I. The core function of a Dual Head Welding Gun: Multi-purpose, handling different pipe diameters

Traditional single-nozzle welding torches often require frequent nozzle changes or repeated flame adjustments when dealing with copper pipes of varying diameters, significantly wasting work time. The Dual Head Welding Gun was designed to solve this problem.

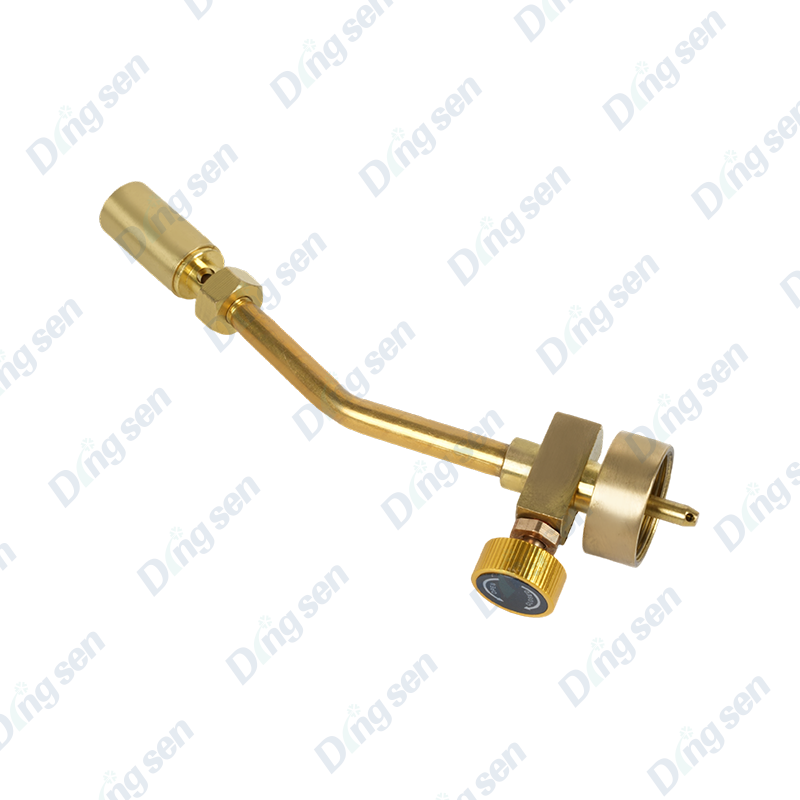

Multi-specification adaptation: This welding torch features a detachable dual-nozzle structure. The two nozzles are designed for small-diameter copper pipes of 6-10mm and 10-16mm respectively.

Seamless switching: When handling different specifications of pipe fittings such as capillary tubes and suction pipes in air conditioning refrigeration systems, repair personnel can quickly complete welding without stopping work to change parts, greatly improving the smoothness of on-site operations.

II. Adaptable to Various Precision Work Scenarios

The dual-head welding torch, with its lightweight design, exhibits exceptional adaptability to various scenarios:

Air Conditioning and Refrigeration Equipment Repair: Whether connecting indoor and outdoor units of split-type or central air conditioning systems, the Dual Head Welding Gun precisely controls heat, preventing damage to surrounding components.

Small Household Appliance Repair: For connecting copper pipes in confined spaces such as refrigerators and freezers, the torch's portability is particularly advantageous.

Precision Hardware Welding: For processing small pipe fittings requiring uniform heating, the dual nozzles provide a more rational heat distribution.

III. Performance Advantages: Safe, Portable, Oxygen-Free

In addition to its versatility, the dual-head welding torch is also highly competitive in terms of technical parameters:

Oxygen-Free: Traditional oxy-fuel welding equipment is bulky and difficult to transport. This dual-head welding torch is suitable for liquefied petroleum gas (LPG) and propane alone, achieving efficient combustion in air, making it ideal for personal repair personnel to carry.

High Safety with Built-in Backfire Prevention Device: Safety during the welding process is paramount. The built-in backfire prevention device effectively eliminates the risk of backflow, ensuring operator safety.

Precise flame control: The unit features a built-in flame adjustment knob, ensuring high flame stability. Even when welding thin-walled copper pipes, it prevents burn-through and blackening.

IV. Why do professional repair technicians prefer dual-head welding torches?

In actual operation, Dual Head Welding Gun products offer significant advantages over traditional single-head torches in terms of efficiency, portability, and safety. Specifically, these advantages are reflected in the following aspects:

A qualitative leap in work efficiency: When dealing with copper pipes of varying thicknesses in air conditioning systems, traditional single-head welding torches often require technicians to stop their work to change the torch tip or force a high flame to weld smaller pipes, easily damaging the pipes. Dual-head welding torches, with their dual-nozzle design, can quickly accommodate welding needs of different diameters (6-16mm) without frequent disassembly, allowing for a seamless operation.

A significant reduction in equipment load: Traditional welding torches typically rely on oxygen cylinders for combustion, making the entire system bulky and inconvenient to move. In contrast, this dual-head welding torch supports single-gas operation with either liquefied petroleum gas (LPG) or propane, completely eliminating the need for oxygen cylinders. Its lightweight design allows for operation with only a single gas cylinder, significantly reducing the physical labor costs associated with working at heights or in confined spaces.

Professional Temperature Control Precision: Traditional welding torches often lack precise flame concentration, easily leading to overheating of thin-walled pipes. The dual-head welding torch features flame optimization for different pipe diameters, and with the flame adjustment knob on the torch body, it delivers extremely stable heat output, ensuring smooth, full welds without burn-through or blackening, resulting in a more professional level of weld quality.

Comprehensive Safety Protection: On-site repair environments are complex, and backfire is the biggest threat to welders. Many traditional, simple welding torches lack protective features, while professional-grade dual-head welding torches come standard with a built-in backfire prevention device. This technical barrier effectively prevents the flame from flowing back into the gas cylinder, providing a solid safety baseline for high-frequency repair work.

The dual-head welding torch is useful not only for its ability to handle copper pipe welding of various diameters, but also for providing the refrigeration repair industry with a low-cost, high-safety, and high-efficiency solution through its innovative dual-nozzle structure and portable design.

-

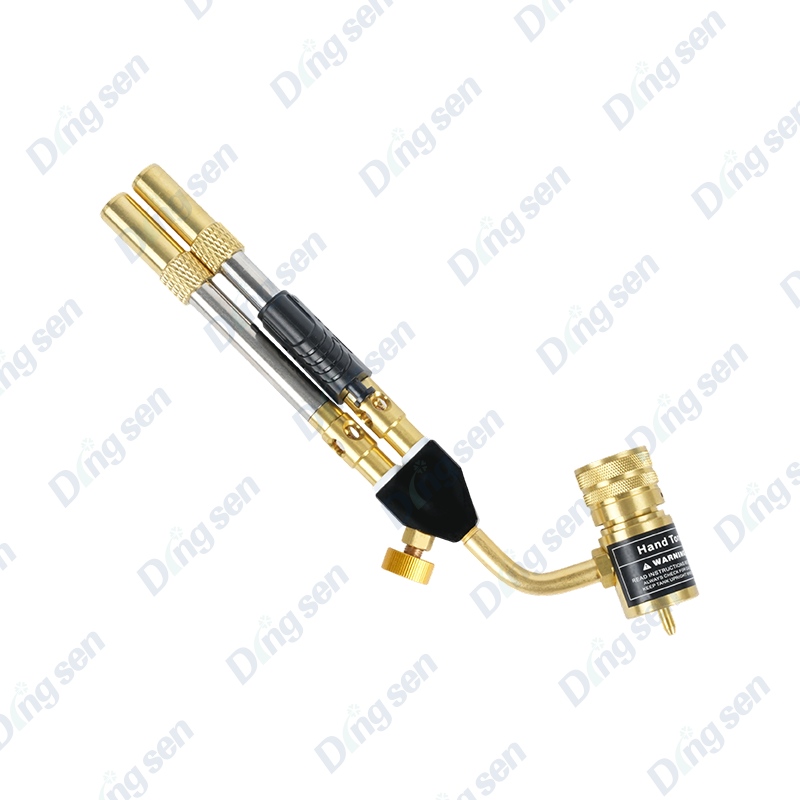

The GB-3T dual nozzle small welding gun is designed for precision operations suc...

-

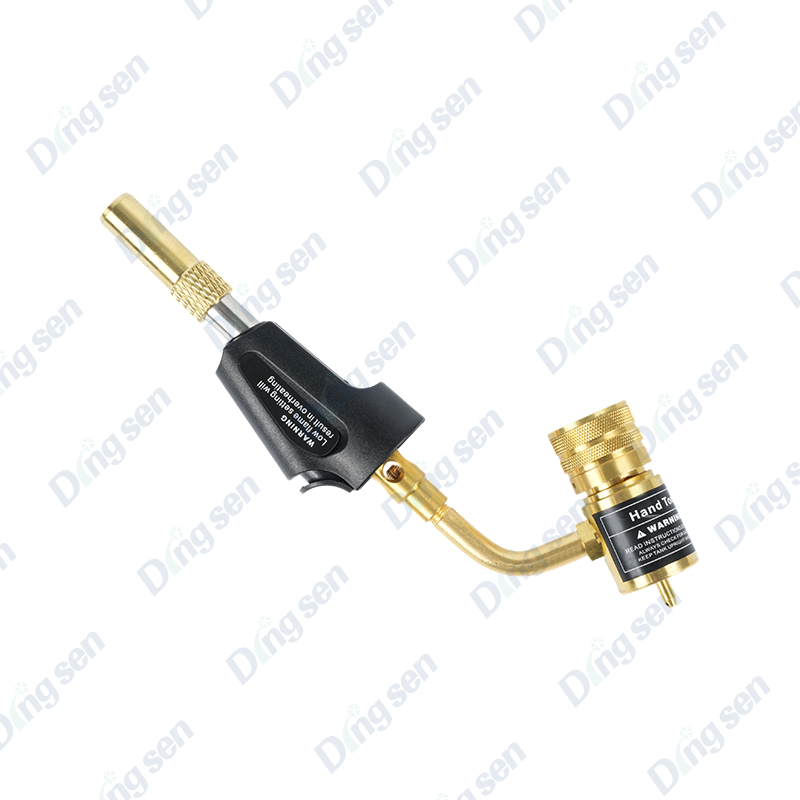

GB-1AT single head welding gun is specially designed for fine scenarios such as ...

-

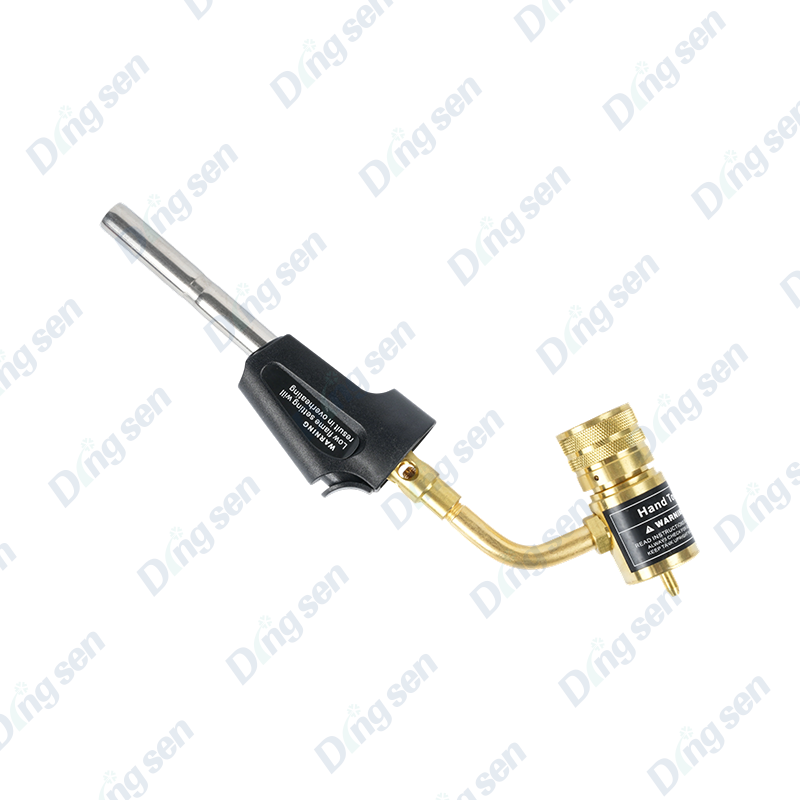

GB-1A single head welding gun focuses on fine welding scenarios such as air cond...

-

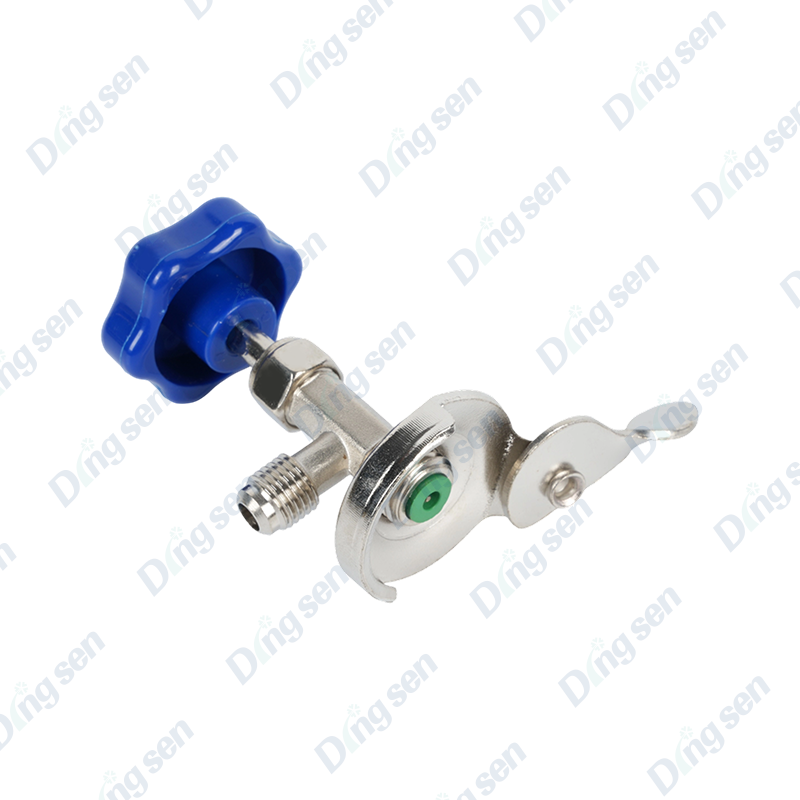

The dispensing valve refrigerant bottle opener is a metal valve-style bottle ope...

-

GB-7 welding gun focuses on medium to high-intensity scenarios such as air condi...

-

GB-1 welding gun is mainly used for lightweight welding scenarios such as air co...

en

en  Español

Español عربى

عربى