Are there significant differences between thickened air conditioner nuts and ordinary nuts?

In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high pressure; while thickened air conditioner nuts, by increasing wall thickness and optimizing brass density, can withstand the higher working pressure of new refrigerants, effectively preventing refrigerant leakage. For household or commercial air conditioning systems that require long-term stable operation, choosing high-quality thickened fittings is key to avoiding expensive repair costs later on.

Core Difference: Why does "thickness" determine safety?

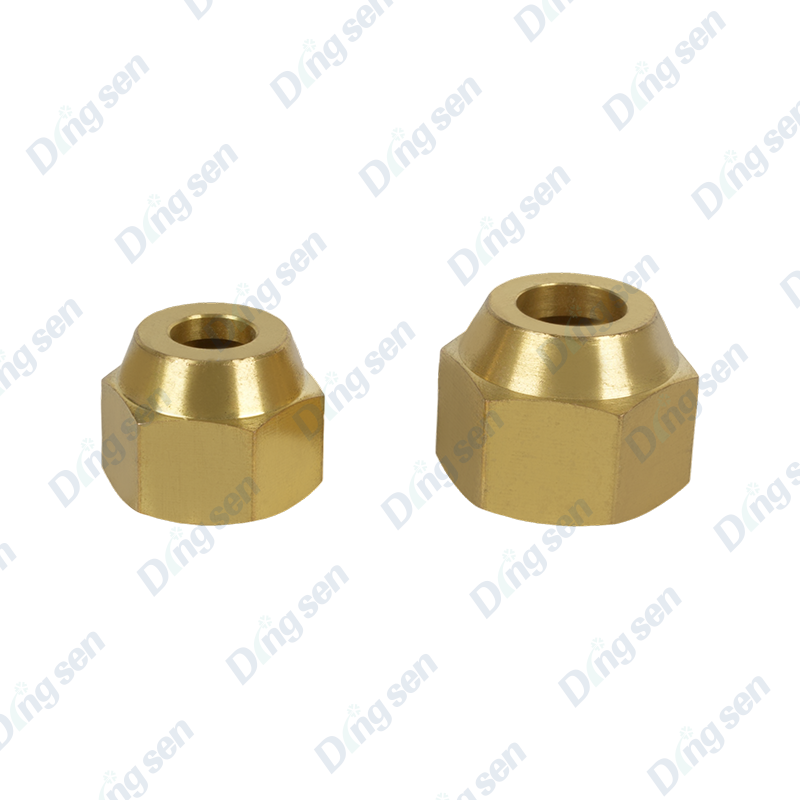

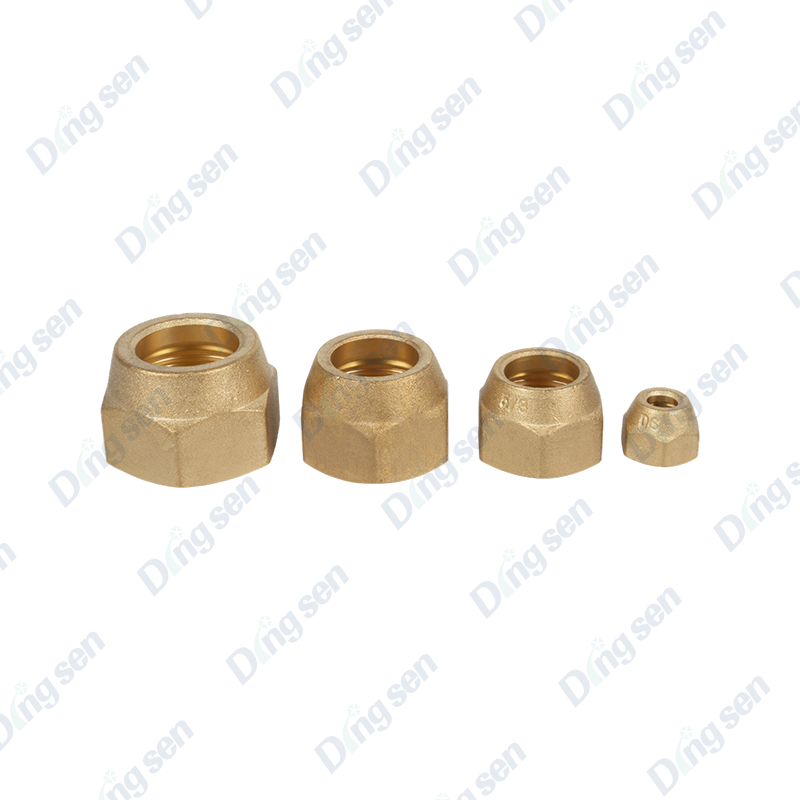

As the core fasteners connecting the indoor and outdoor copper pipes of the air conditioner, air conditioner nuts (commonly known as flare nuts) bear enormous system pressure.

1. Difference in Pressure Bearing Capacity

Modern inverter air conditioners generally use environmentally friendly refrigerants, whose system pressure is about 1.6 times higher than traditional refrigerants. Ordinary air conditioner nuts are prone to stress fatigue in weak areas under long-term high-pressure vibration. Thickened air conditioner nuts increase the thickness of the thread root, easily coping with high-pressure impact and ensuring that the flared connection remains tight and secure.

2. Material and Processing Technology

Ordinary nuts: Mostly made of ordinary cast brass or recycled copper, which may contain pores and have low tensile strength.

Thickened air conditioner nuts: High-quality manufacturers usually select HPb59-1 refined brass and process it using cold forging or hot stamping. This process makes the metal molecular structure tighter, the threads more precise and wear-resistant, and less prone to stripping even after multiple disassemblies.

Preventing Refrigerant Leaks: The "practical" advantages of thickened nuts

Refrigerant leakage is a "chronic problem" in the air conditioning industry, and 90% of leaks occur at the joints.

Mitigating Thermal Expansion and Contraction: When the air conditioner switches between cooling and heating modes, the copper pipes undergo frequent thermal expansion and contraction. The thermal expansion coefficient of thickened air conditioner nuts is closer to that of copper pipes, and the thicker cavity can absorb the deformation stress caused by temperature differences, preventing the nut from cracking due to excessive contraction in severe winter conditions.

Higher tightening torque: Installation workers often apply more force with the wrench to ensure a proper seal. Ordinary nuts, due to their thin walls, are prone to "lateral fracture" from excessive force; the thickened design allows for a greater installation torque, ensuring the pressure on the sealing surface meets the standard.

How to identify high-quality air conditioner nuts?

As a professional manufacturer of air conditioner nuts, we recommend paying attention to the following three points when purchasing:

Weight: For nuts of the same specification, the thickened version is noticeably heavier.

Appearance: High-quality nuts have a uniform light yellow surface (the natural color of brass), with clear threads and no burrs.

Inner chamfer: The smoothness of the chamfered edge at the flared connection directly affects the tightness of the fit with the copper pipe.

Although the unit price of thickened air conditioner nuts is slightly higher than that of ordinary models, considering the cost of a service call and refrigerant refill required for a leak repair, using high-quality air conditioner nuts is extremely cost-effective.

-

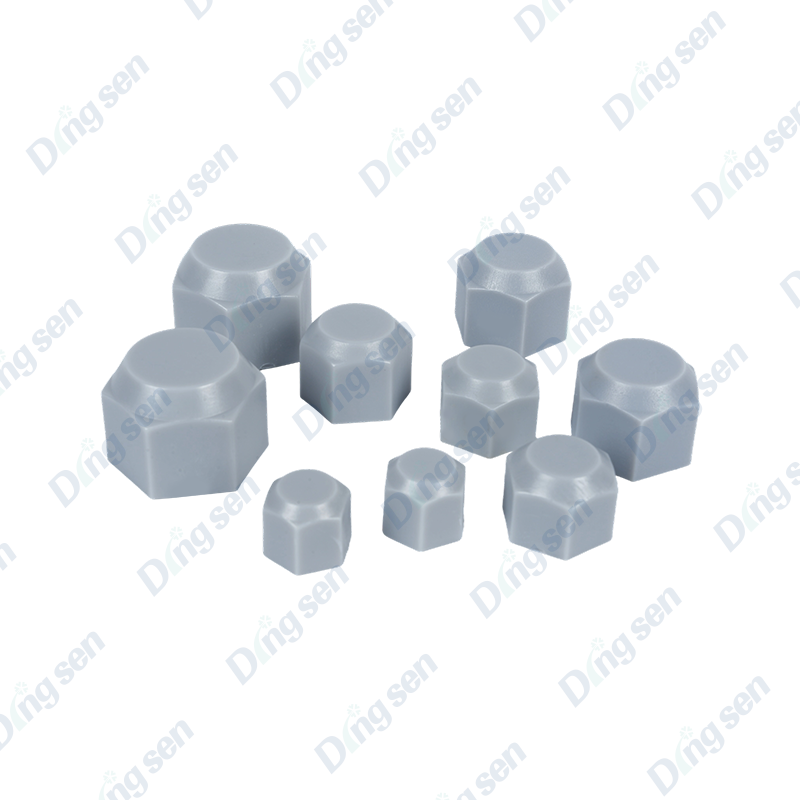

Air conditioning plastic nuts are lightweight seals for connecting copper pipes ...

-

Air conditioning reducing nuts are sealed connectors for connecting copper pipes...

-

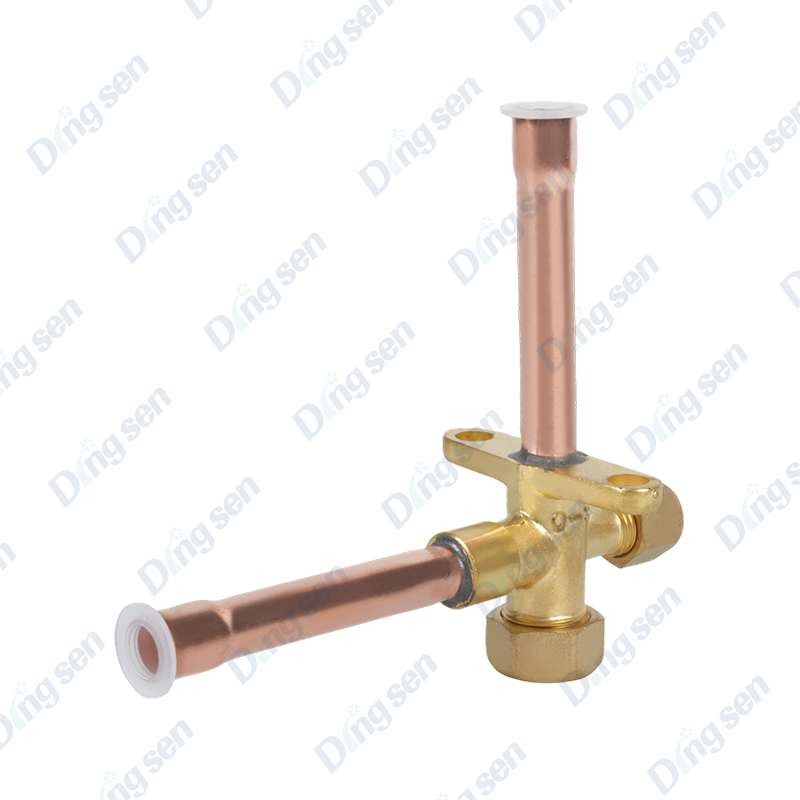

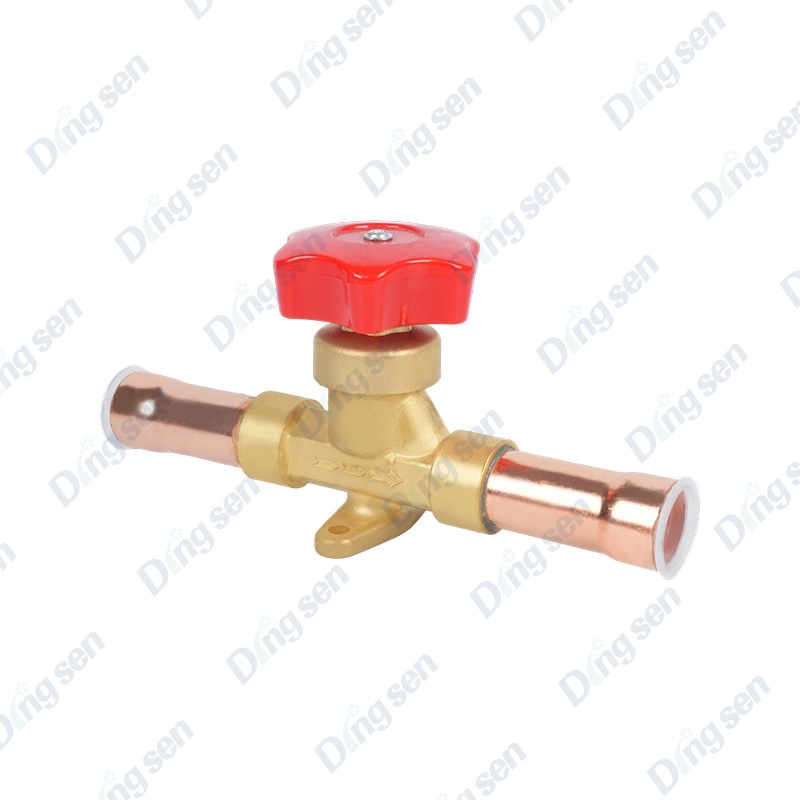

The air conditioning three-way valve is a key component for switching and contro...

-

Air conditioning nuts are core fasteners for connecting copper pipes in air cond...

-

Diaphragm-type hand valves are manual flow control components for refrigeration ...

-

The car air conditioning fluorine charging guage is a dedicated instrument for r...

en

en  Español

Español عربى

عربى