In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

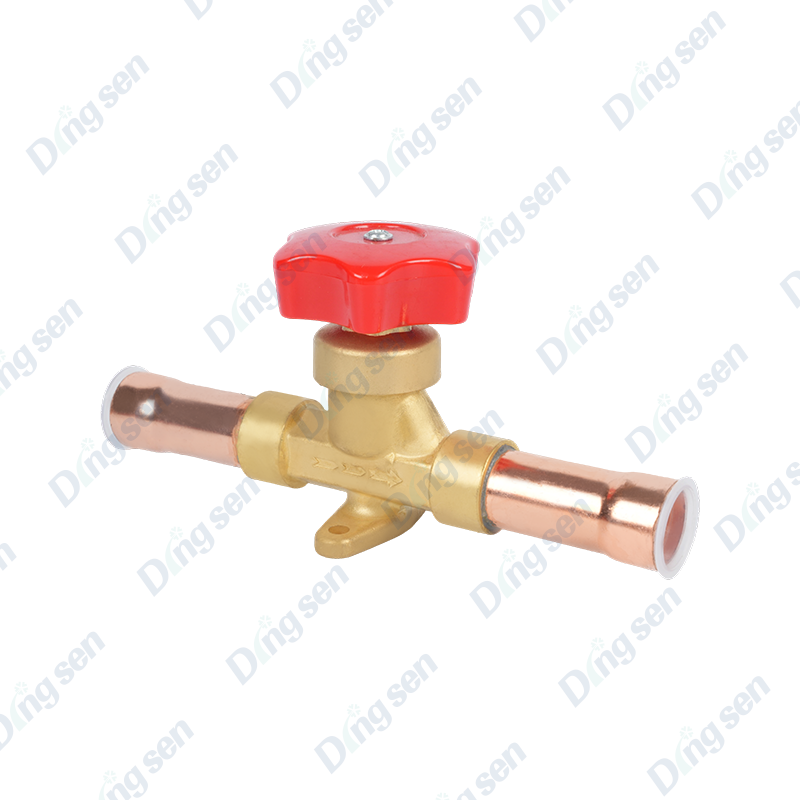

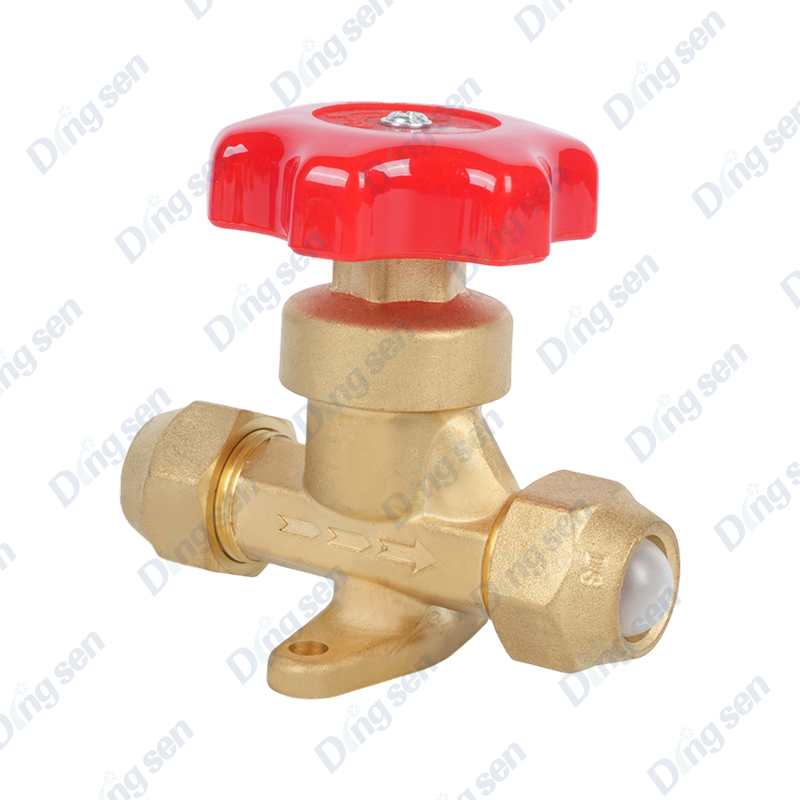

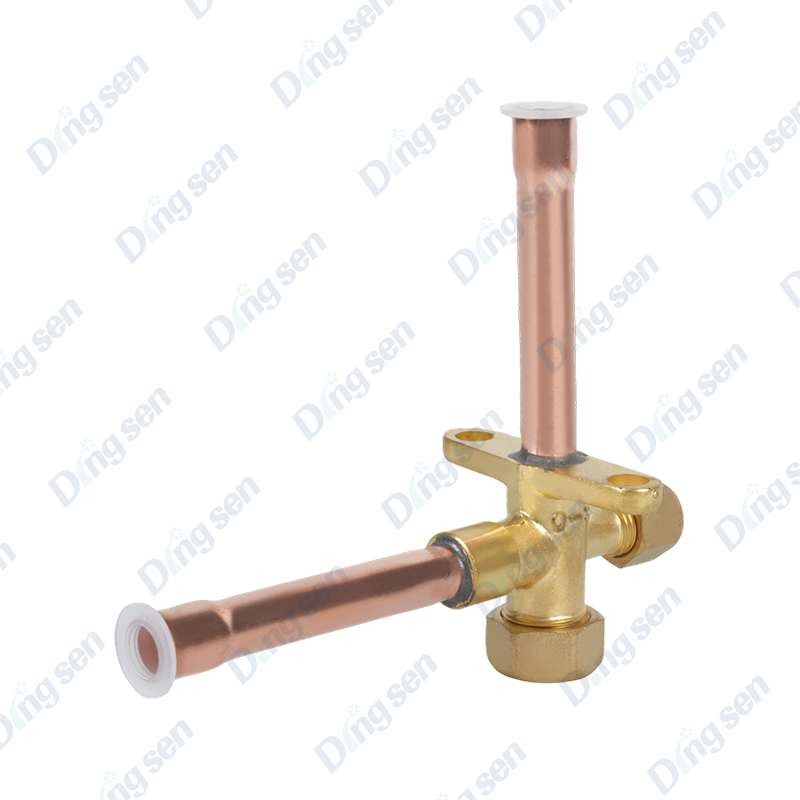

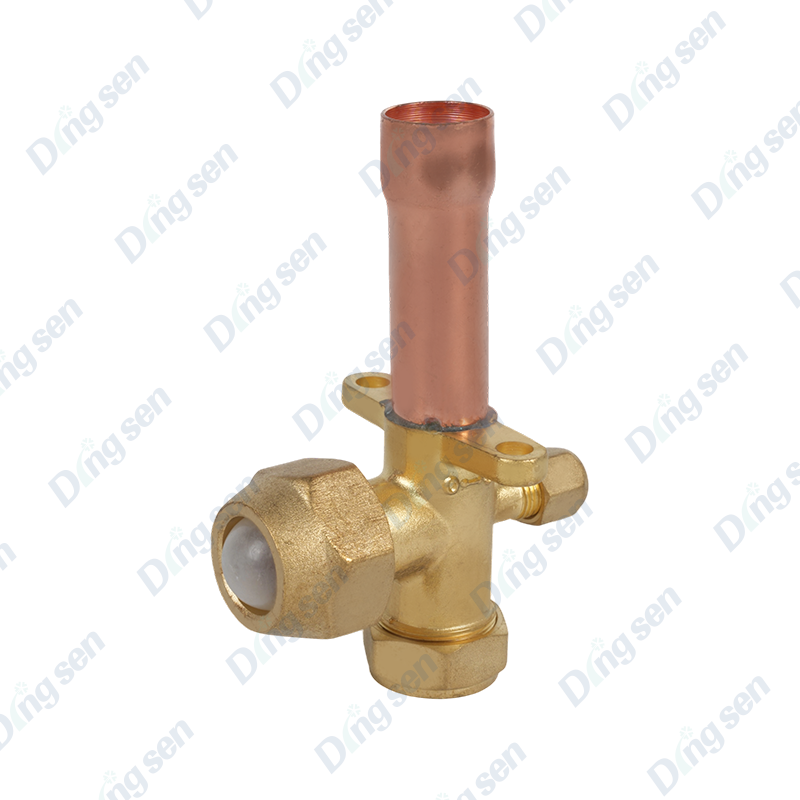

READ MOREDiaphragm-type hand valve

Diaphragm-type hand valves are manual flow control components for refrigeration systems. They precisely control the flow of media and flow rate by manually rotating the diaphragm opening, suitable for unidirectional flow.

They are used in liquid and air intake lines in refrigeration, refrigeration, and air conditioning systems.

Manufactured using corrosion-resistant materials according to standards, they undergo sealing and pressure resistance testing.

Pre-sales selection and after-sales maintenance guidance are provided, offering precise adjustment, excellent sealing, easy operation, and a long service life.

This diaphragm-type hand valve, a dedicated manual shutoff component for refrigeration systems, utilizes a diaphragm-actuated mechanism. Manual rotation of the diaphragm opening controls the flow of media and flow rate. It strictly restricts fluid flow to one direction, effectively preventing system pressure imbalances or component damage caused by refrigerant backflow. It ensures precise control of the flow direction and meets the needs of unidirectional flow control in various operating conditions. This hand valve is widely applicable in refrigeration systems, refrigerators, and air conditioning units. Specifically, it can be installed in the system's liquid pipeline (for precise control of refrigerant liquid delivery rate), suction pipeline (for stable regulation of return air flow to ensure efficient compressor operation), and hot gas pipeline (for controlling hot gas bypass to balance system temperature). This applies to a wide range of equipment, including residential central air conditioners, commercial refrigerated display cabinets, and small industrial cold storage, providing reliable support for media control in refrigeration systems.

In terms of interface specifications, this hand valve is divided into two categories: the first is a threaded connection (SAE), offering a full range of thread sizes from 1/4 SAE to 3/4 SAE, suitable for piping applications requiring easy disassembly, eliminating the need for specialized welding tools for installation and maintenance; the second is an open-end welded connection (ODF), covering interface sizes from 1/4" to 7/8", providing more stable sealing performance after welding and suitable for refrigeration pipelines with long-term operation and high sealing requirements. Both interface types can meet different installation environments and usage requirements.

-

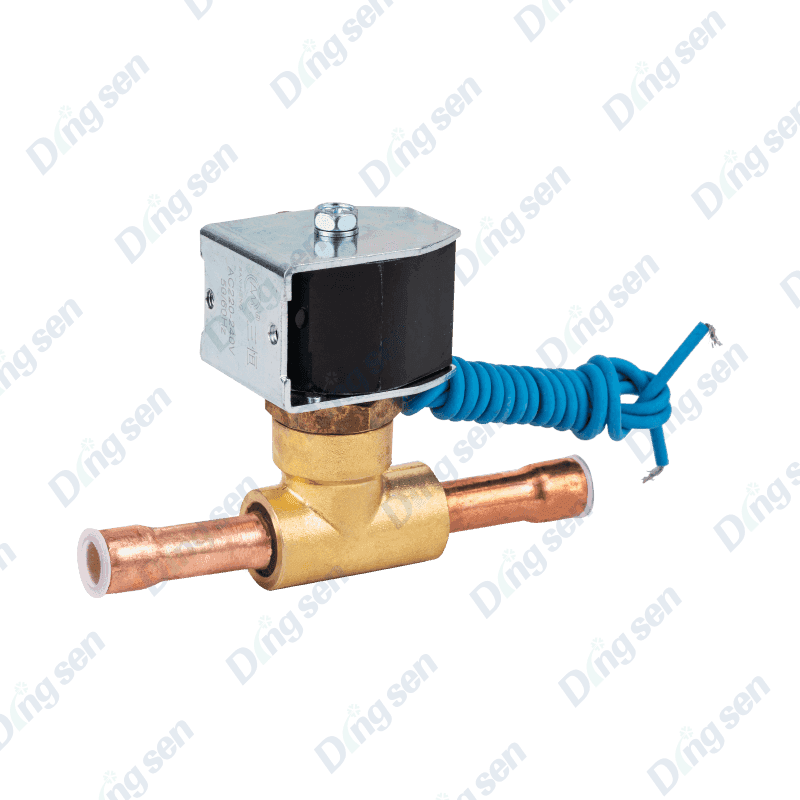

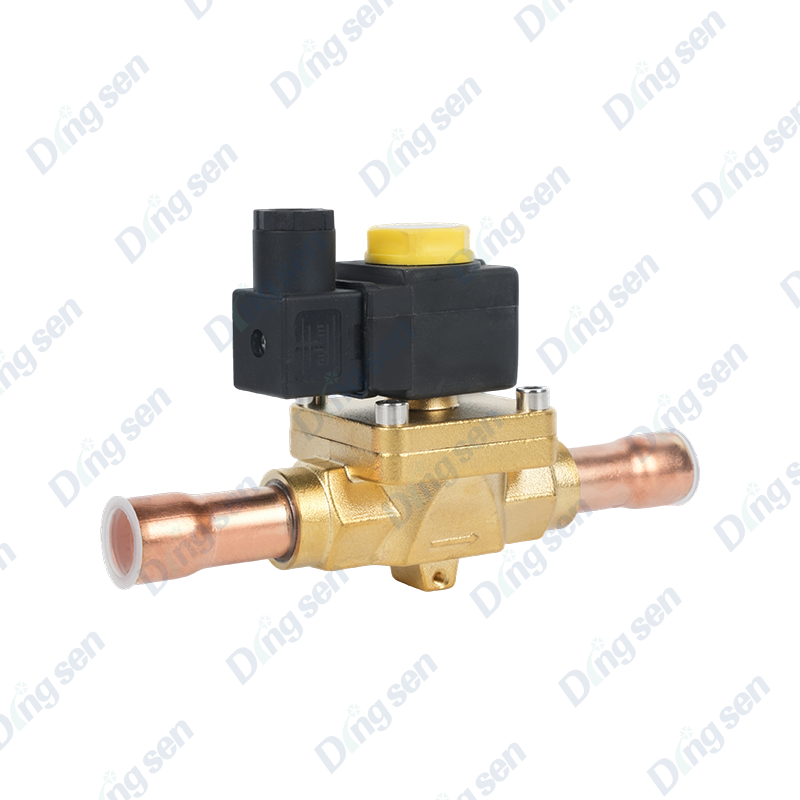

The FDF type solenoid valve is a highly reliable valve designed specifically for...

-

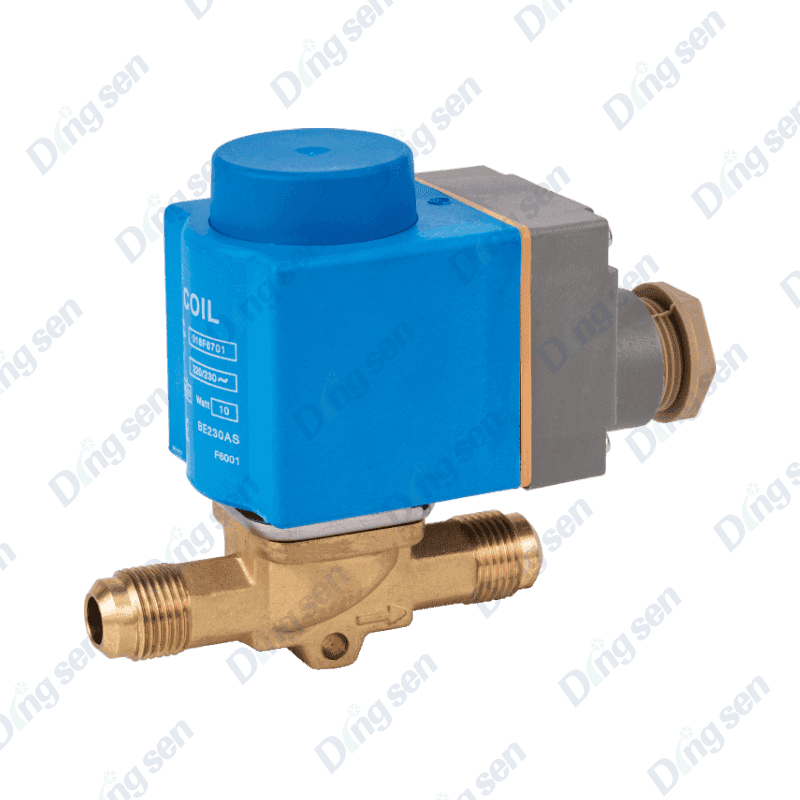

The EVR type solenoid valve features a split upper and lower structure, with a b...

-

The air conditioning three-way valve is a key component for switching and contro...

-

EVR solenoid valves are key components in refrigeration and air conditioning, co...

-

The air conditioning three-way valve is a key component for switching and contro...

-

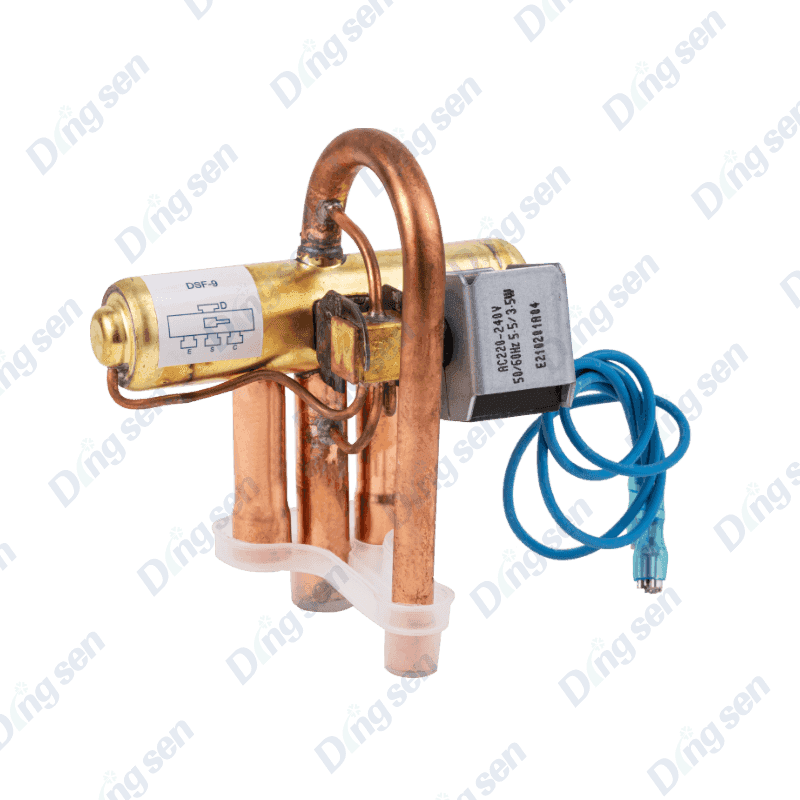

A four-way reversing valve is a key component for switching the flow of fluids (...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى