What is the working principle of a cylinder valve?

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation of mechanical devices.

Specifically, when a solenoid coil or manual device triggers the valve to open, compressed air enters the cylinder through the inlet, pushing the piston to move. When the valve closes or reverses direction, the airflow direction changes, and the piston returns to its original position or moves in the opposite direction. This principle enables cylinder valves to play a crucial role in power transmission and precise control in industrial automation.

Core Structure and Working Process of a Cylinder Valve

A cylinder valve typically consists of a valve body, piston, seals, and a drive device (such as a solenoid). In a pneumatic system, when a control signal is sent to the valve, its internal channels rapidly switch to guide the airflow.

For example, in a double-acting cylinder valve, air alternately enters both ends of the cylinder to ensure the reciprocating motion of the piston; while a single-acting cylinder valve relies on spring force for return. This design not only improves the efficiency of pneumatic control but also ensures the stability of equipment under high temperature and high pressure environments. With the rapid development of industrial automation, the response speed and durability of cylinder valves have become key indicators for measuring their performance.

Types and Applications of Cylinder Valves

There are many types of cylinder valves, including solenoid valves, manual valves, and mechanical valves, each suitable for different scenarios. In manufacturing, solenoid cylinder valves, with their remote electrical control advantages, are widely used in assembly line robotic arms and packaging equipment; in the automotive industry, cylinder valves drive assembly tools to complete precision operations. Furthermore, hydraulic and pneumatic systems are often used in combination to meet higher load requirements.

In recent years, with the advancement of intelligent manufacturing, intelligent cylinder valves integrate sensors to monitor pressure and position in real time, further optimizing energy consumption and production safety. Related terms such as fluid control and actuators also highlight their core position in the field of automation.

Industry Trends and Technological Innovation

With the deepening of Industry 4.0, cylinder valve technology is developing towards higher efficiency and intelligence. New low-power cylinder valves utilize energy-saving materials, reducing air consumption; while IoT integration provides fault prediction capabilities, lowering maintenance costs. Simultaneously, miniature cylinder valves are emerging in medical devices and electronic equipment, demonstrating the expanding applications of precision engineering.

In the future, cylinder valves will be combined with artificial intelligence to achieve adaptive control, driving innovation in industrial automation solutions. These advancements not only improve production efficiency but also strengthen the market competitiveness of cylinder valves as key components.

Although the working principle of cylinder valves is based on simple pneumatic conversion, their design and technological evolution have profoundly impacted modern industry. From basic manufacturing to high-end intelligent systems, the efficient control and reliability of cylinder valves continue to drive automation progress.

-

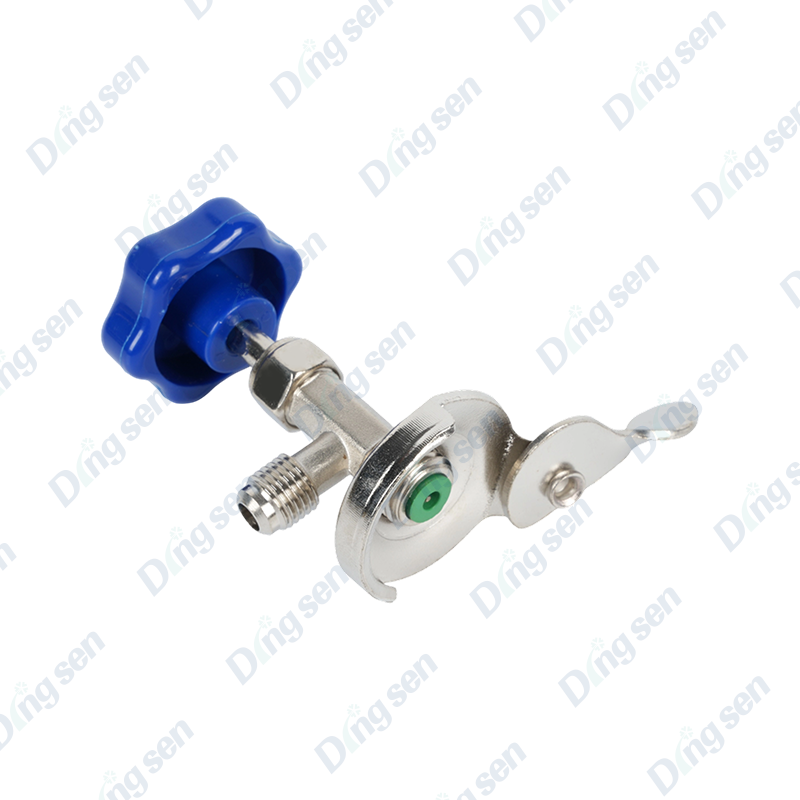

The dispensing valve refrigerant bottle opener is a metal valve-style bottle ope...

-

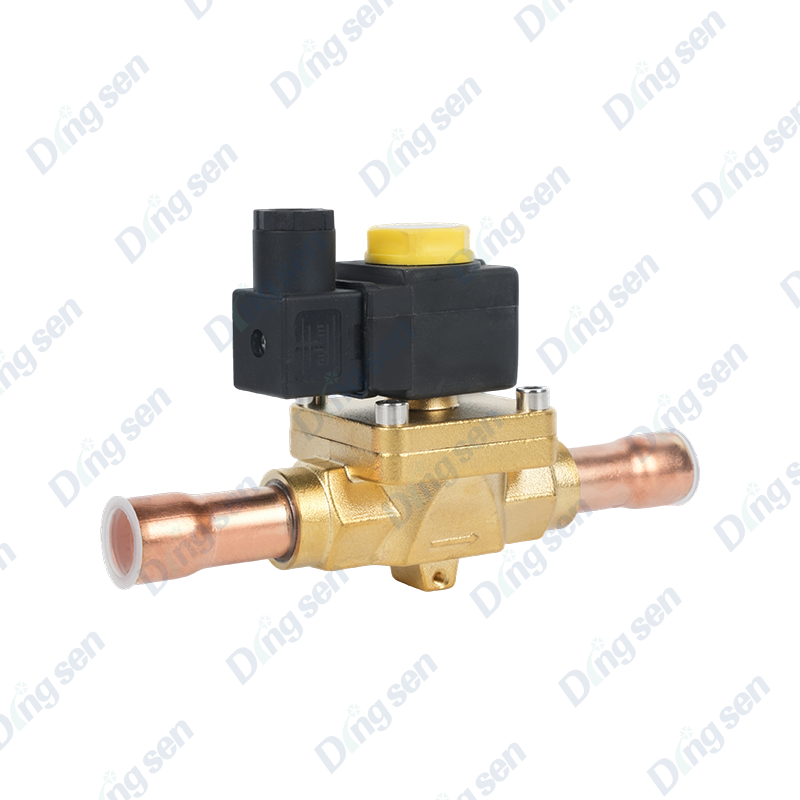

EVR solenoid valves are key components in refrigeration and air conditioning, co...

-

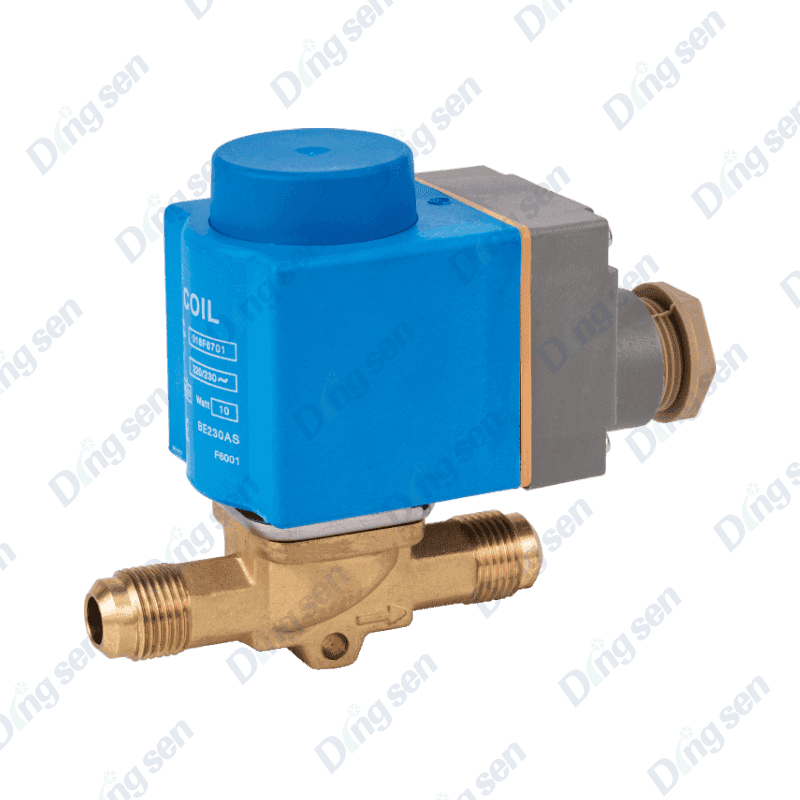

The EVR type solenoid valve features a split upper and lower structure, with a b...

-

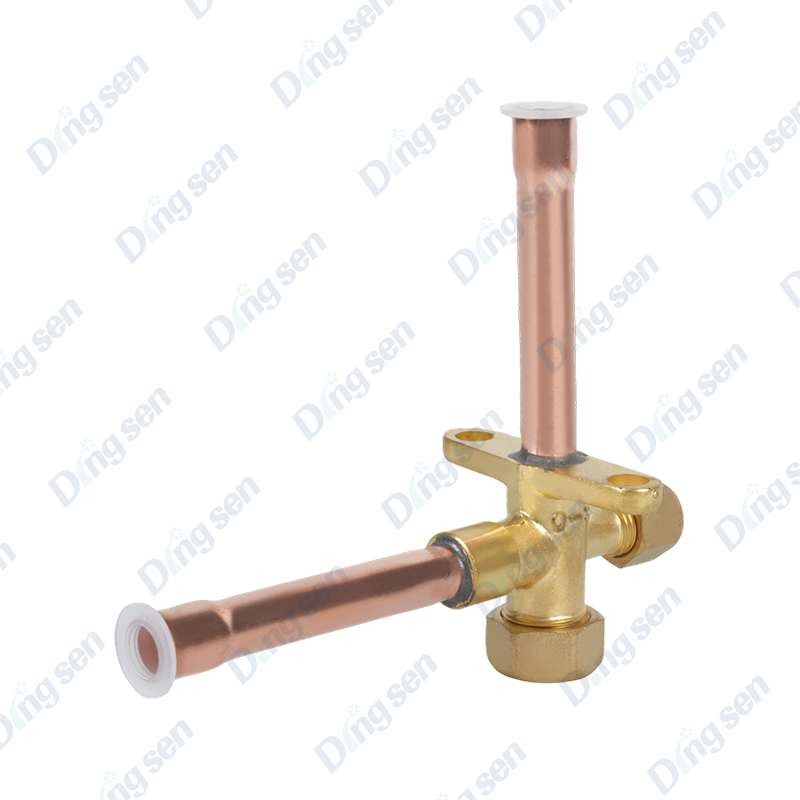

The Safety filling valve series is a safety control component during media filli...

-

The air conditioning three-way valve is a key component for switching and contro...

-

The air conditioning three-way valve is a key component for switching and contro...

en

en  Español

Español عربى

عربى