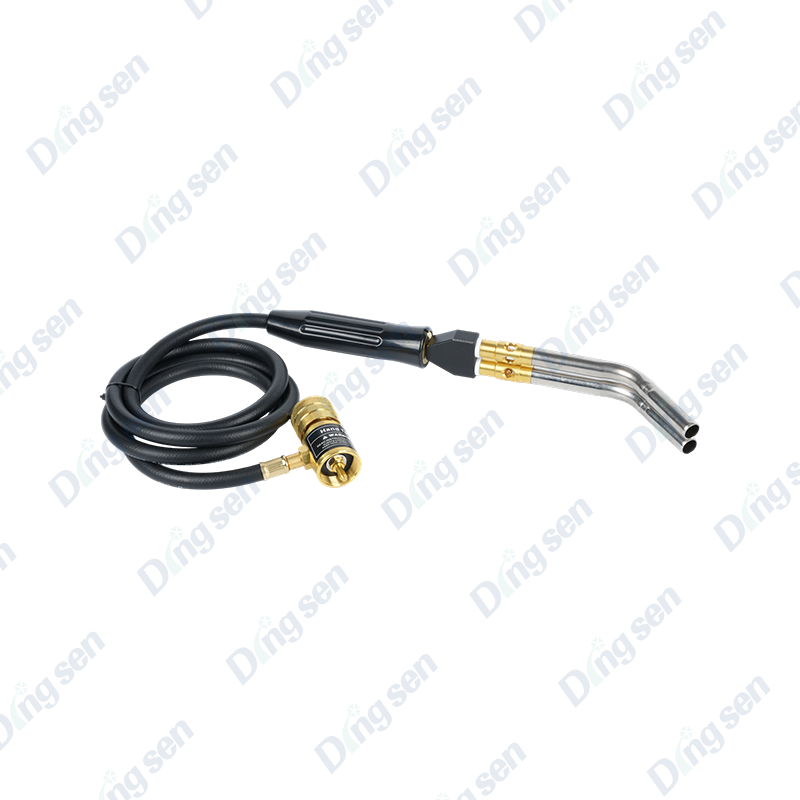

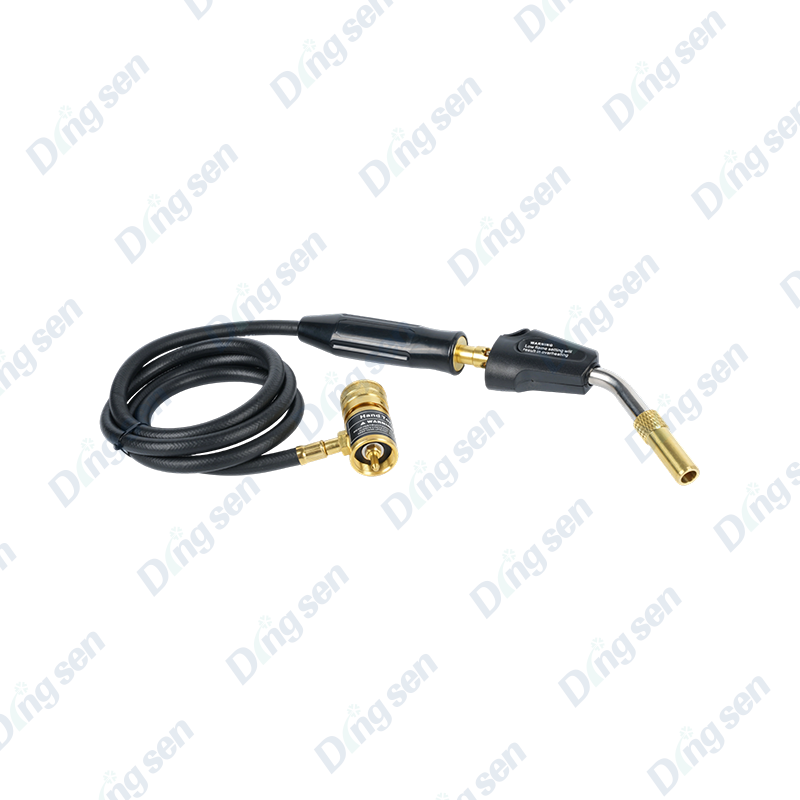

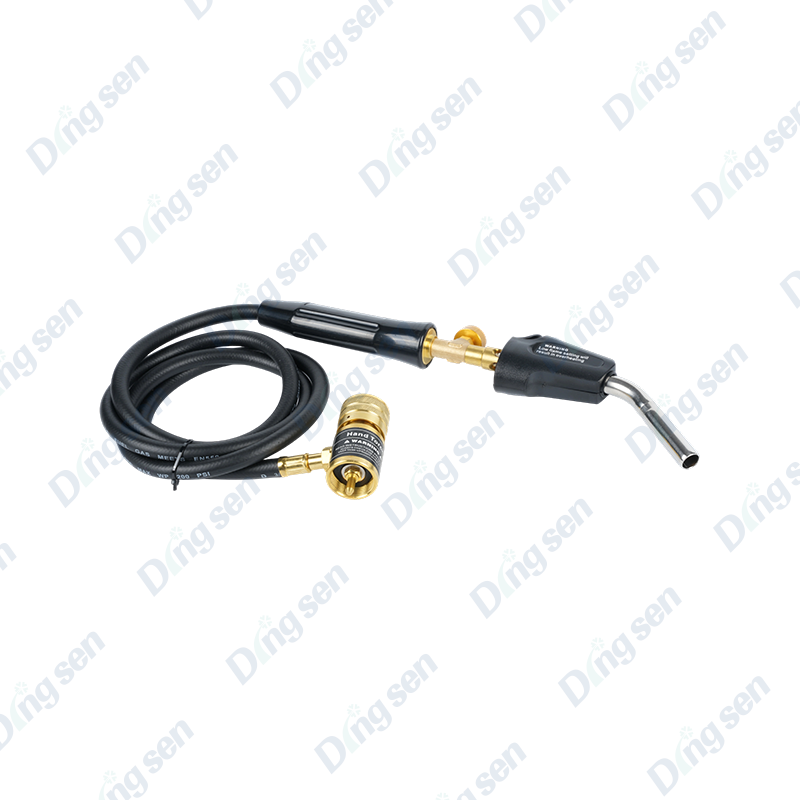

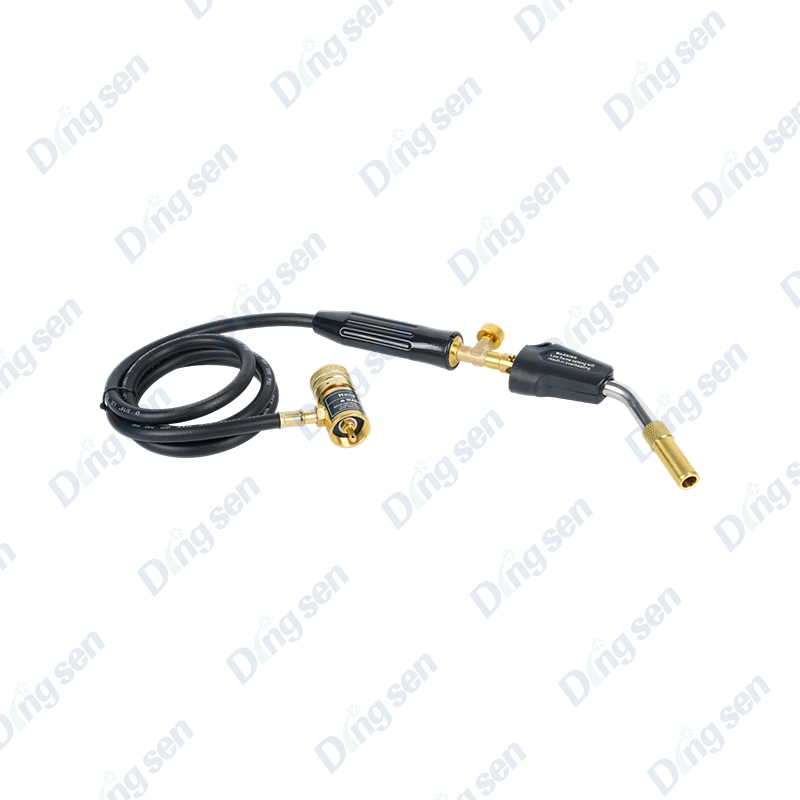

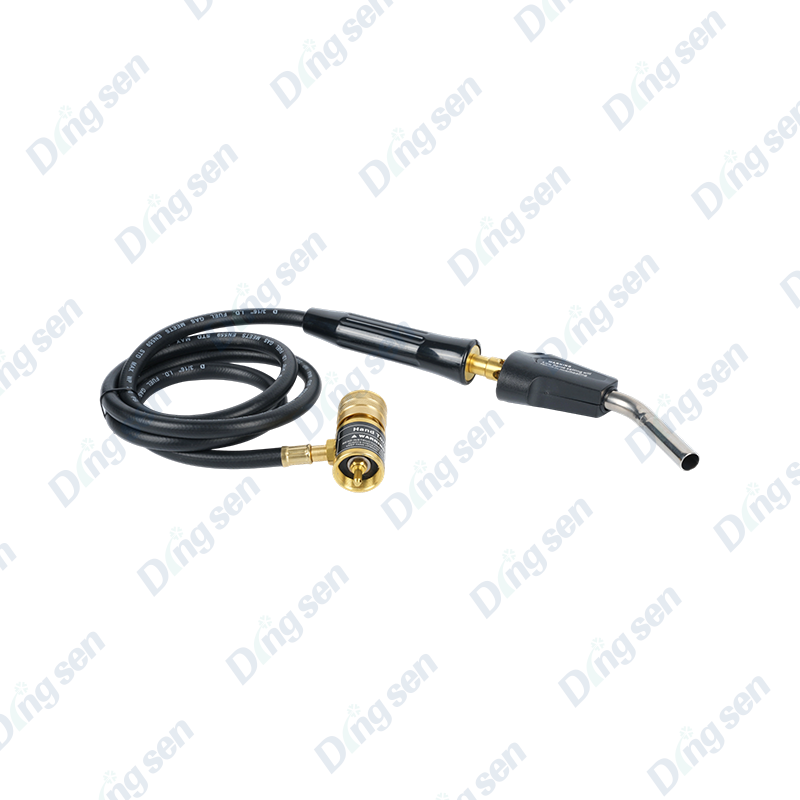

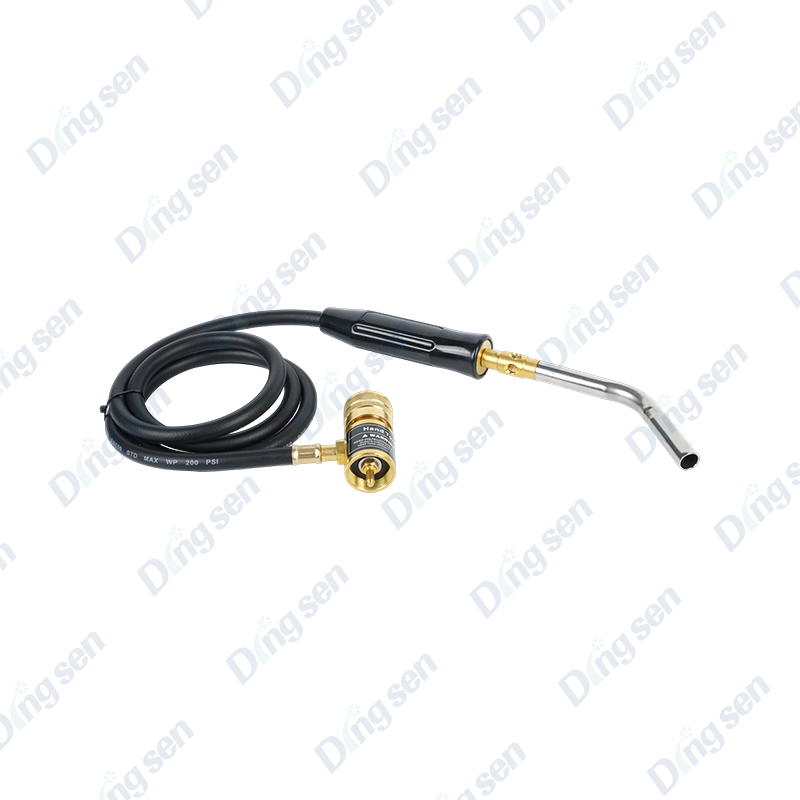

This series of oxygen-free welding torches is a professional tool designed for high-performance maintenance of refrigeration equipment and copper pipe connections. Utilizing oxygen-free combustion technology, it is compatible with liquefied petroleum gas (LPG) or propane fuels, combining portability and superior welding efficiency, making it an ideal choice for the high-end market.

I. Superior Quality Stems from Strict Control

Our quality control is highly consistent with your company's standards for its products:

Quality Foundation: We possess our own testing laboratory equipped with state-of-the-art and comprehensive testing equipment, ensuring that every oxygen-free welding torch leaving the factory undergoes rigorous performance and safety verification.

High-End Material Guarantee: Strict control over the price, quality, and supply of raw materials lays a solid foundation for the continuous production of high-quality products that meet international standards.

Compliance with International Standards: Our product design and manufacturing strictly adhere to international standards, primarily exporting to markets with extremely high quality requirements, such as Europe, America, and Japan.

II. Performance Tiers and Technical Highlights

As a high-efficiency handheld welding torch, we offer solutions at different levels:

Entry-level: Focused on basic maintenance, ensuring high flame stability, suitable for welding copper pipes with diameters ranging from 6mm to 12mm.

Intermediate-level: Equipped with an adjustable flame knob, applicable to copper pipes with diameters from 12mm to 20mm.

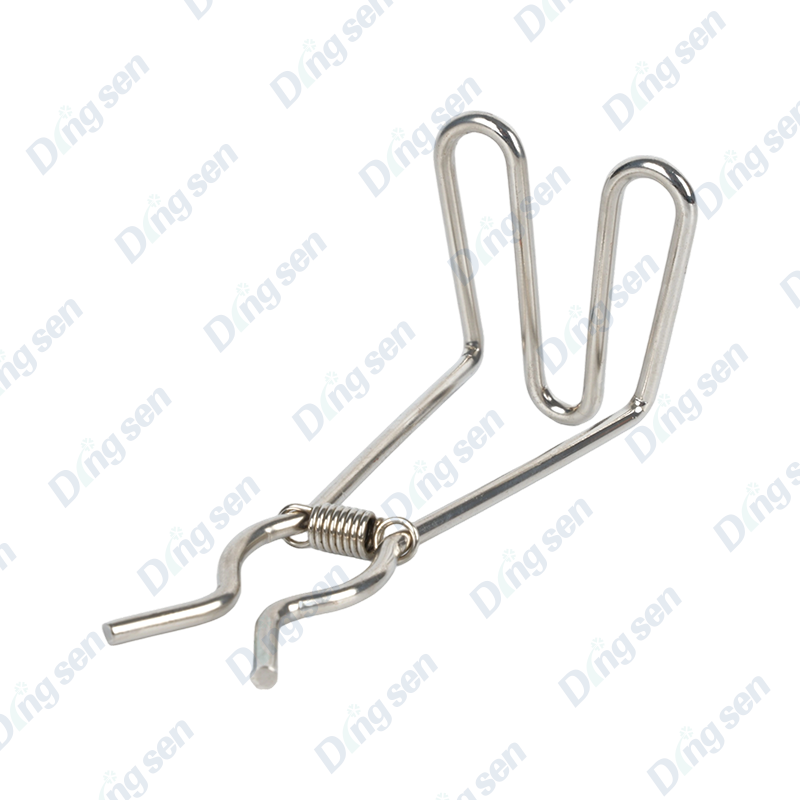

Professional-level: Designed for complex working conditions, including a backfire prevention device and a high-temperature resistant brass welding torch head, representing our high-end manufacturing capabilities.

III. Core Advantages and Operational Flexibility

Single Fuel System: Eliminates the need for oxygen cylinders, significantly simplifying carrying and operation, and improving on-site mobility.

Handheld Design Essence: All oxygen-free welding torch models feature optimized ergonomic design, ensuring stable operation for extended periods without fatigue when used as a handheld welding torch.

Fuel Performance Extension: Intermediate and professional-grade equipment is compatible with MAPP gas welding torch fuel, significantly increasing flame temperature and welding speed, especially suitable for rapid welding of high thermal conductivity copper pipes.

IV. Quality Assurance and Material Durability

Weld Quality: Optimized nozzle design ensures concentrated flame, achieving rapid and uniform heating of the copper pipe, guaranteeing high weld smoothness and excellent airtightness.

Material Guarantee: Key components of the welding torch (such as the nozzle) are made of corrosion-resistant and high-temperature-resistant special metal materials, ensuring long-term reliable operation of the equipment under frequent use.

Rapid Response System: The company employs a comprehensive ERP system, providing 24/7 availability and extremely fast response to orders and demands. Processing can be completed within 15-30 minutes, ensuring rapid delivery capabilities for international clients.

Fuel Compatibility: Advanced models support MAPP gas welding torch mode, further enhancing the operational efficiency of professional customers under demanding deadlines.

en

en  Español

Español عربى

عربى