In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

READ MORECharging valve

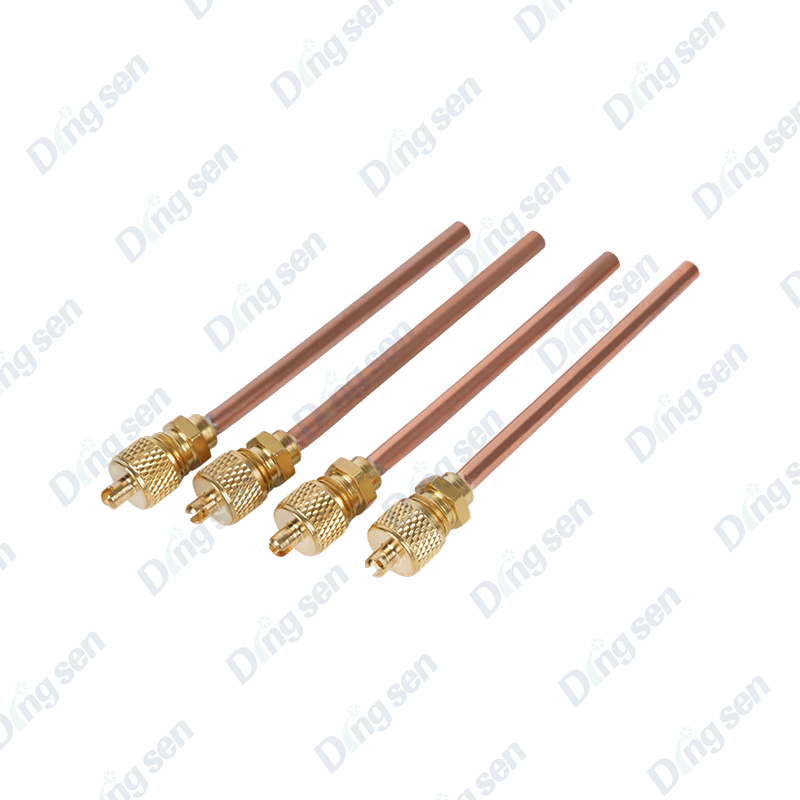

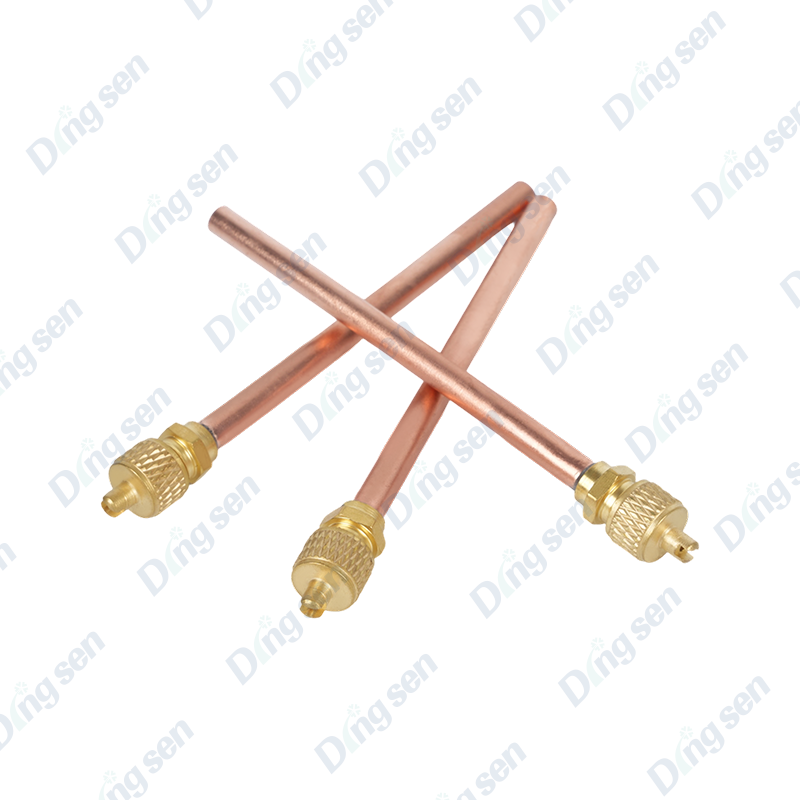

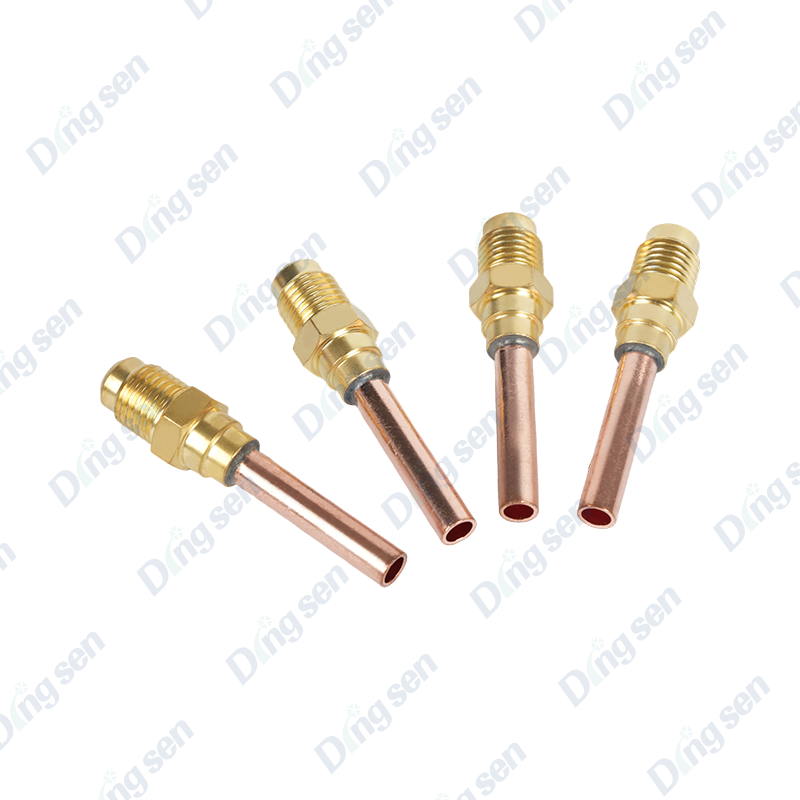

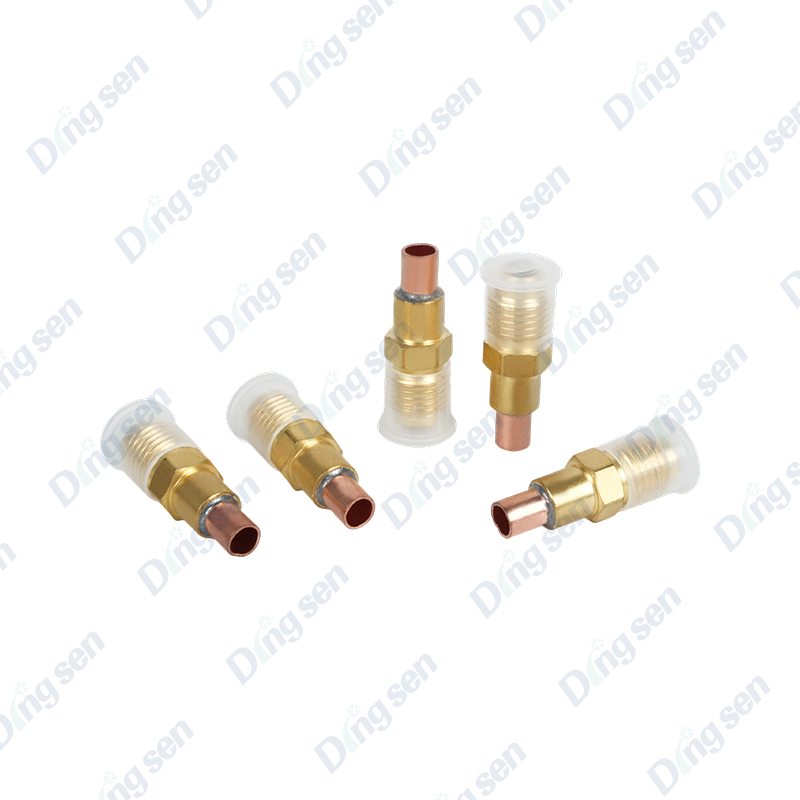

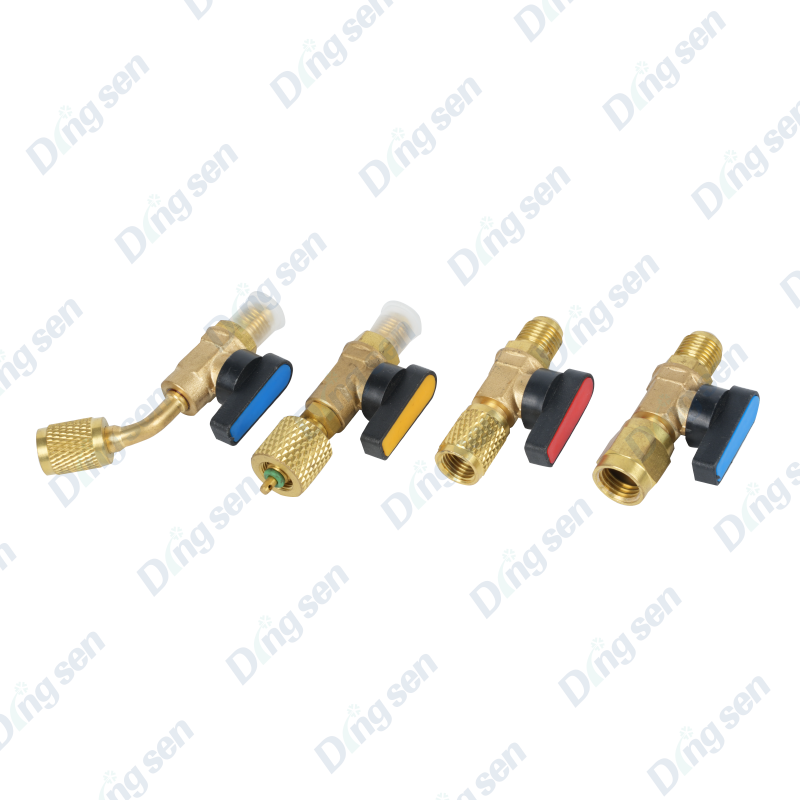

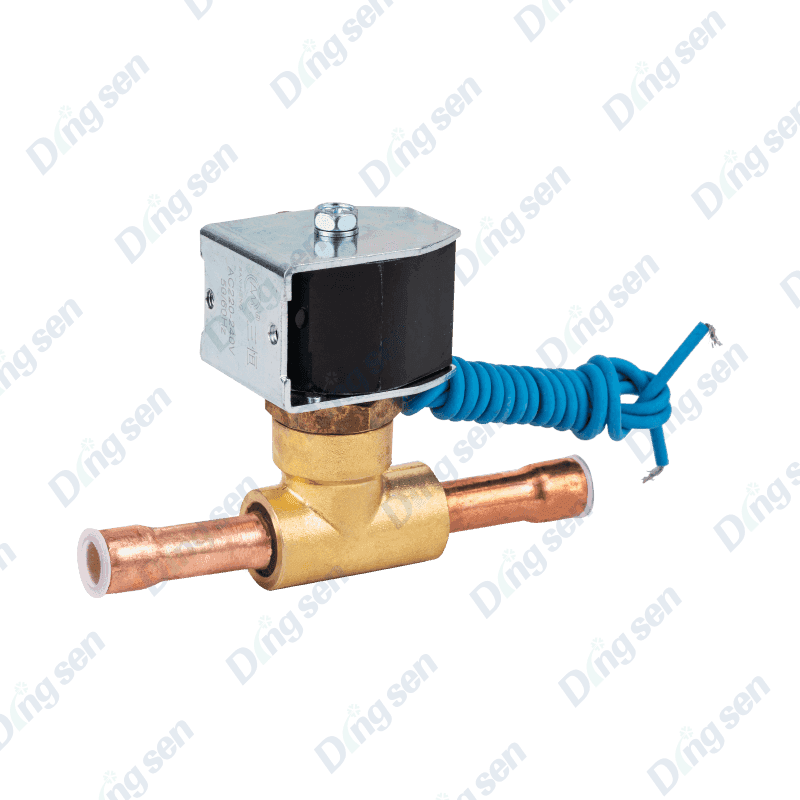

Charging valves are specialized control components for refrigerant charging in refrigeration systems. They precisely control the refrigerant charge volume and provide a leak-proof seal, ensuring a safe and efficient charging process.

They are suitable for refrigerant charging lines in air conditioners, refrigeration equipment, and refrigeration units, meeting diverse charging requirements.

Manufactured from corrosion-resistant materials, they undergo precision machining, sealing, and pressure testing to ensure reliable performance.

Service includes pre-sales selection and after-sales maintenance guidance. Advantages include precise control, excellent sealing, wide compatibility, and easy operation.

Charging valves are specialized, one-way service valves with a valve core in refrigeration systems. Their core function is to provide precise control for refrigerant charging and maintenance in the system, while ensuring unidirectional flow and preventing reverse leakage. They are critical components for the maintenance and operation of refrigeration, refrigeration, and air conditioning equipment.

This product is widely used in key piping systems in refrigeration equipment, refrigeration units, residential and commercial air conditioners, and other air conditioning systems. Whether performing initial refrigerant charging, subsequent replenishment, or pressure testing during system maintenance, it provides stable performance and adapts to operational needs under diverse operating conditions. In terms of performance and design, the charging valve offers multiple core advantages: It utilizes imported valve cores made of rigorous materials and craftsmanship, ensuring stable and reliable performance over long-term use and reducing the risk of failure. Its innovative double-seal structure eliminates refrigerant leaks at the source, ensuring operational safety and system efficiency. It can accommodate copper tubes of varying lengths and hardnesses to meet specific installation requirements, enhancing piping compatibility. The knurled design of the valve cap increases hand friction, eliminating the need for additional tools during installation and removal, making operation convenient and efficient, significantly reducing the workload for maintenance personnel.

-

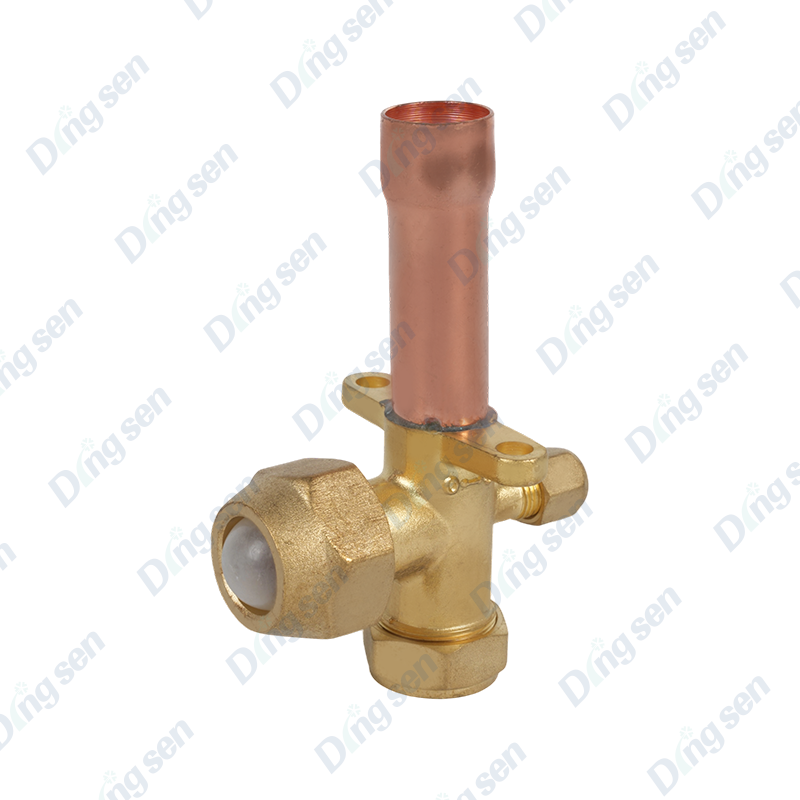

Charging Ball Valve is a core control component in the refrigeration, chemical, ...

-

Air conditioning refrigerant ball valve are core components for fluid control in...

-

The air conditioning three-way valve is a key component for switching and contro...

-

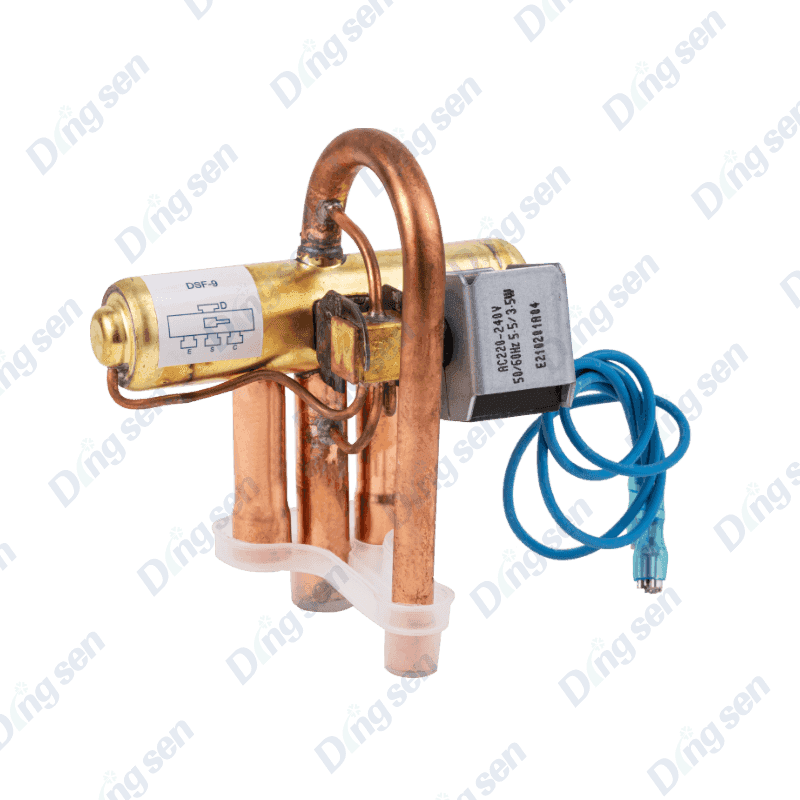

A four-way reversing valve is a key component for switching the flow of fluids (...

-

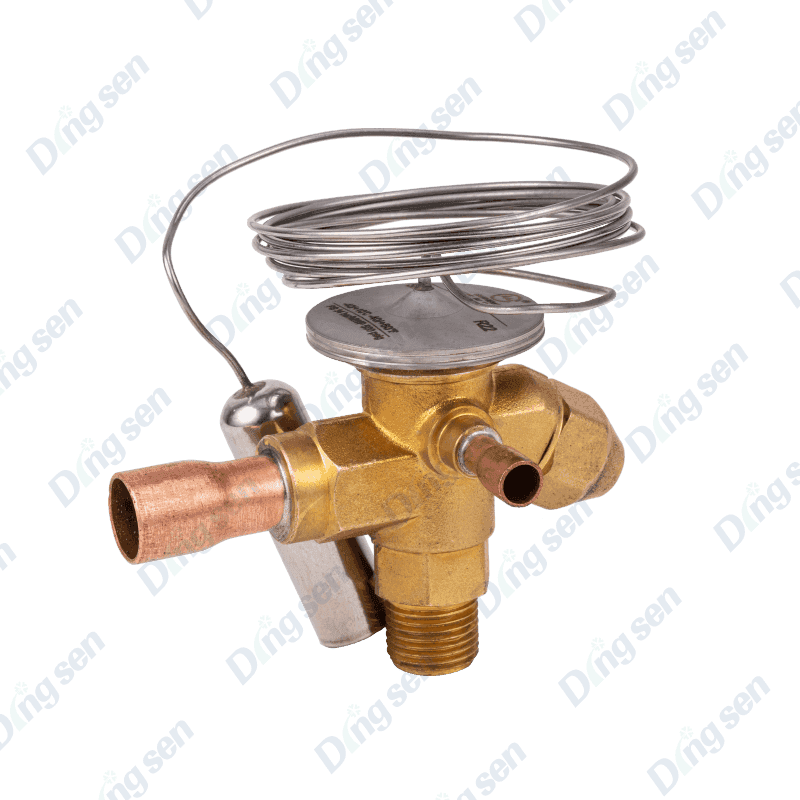

The thermal expansion valve features a compact body constructed of brass or stai...

-

The FDF type solenoid valve is a highly reliable valve designed specifically for...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى