In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

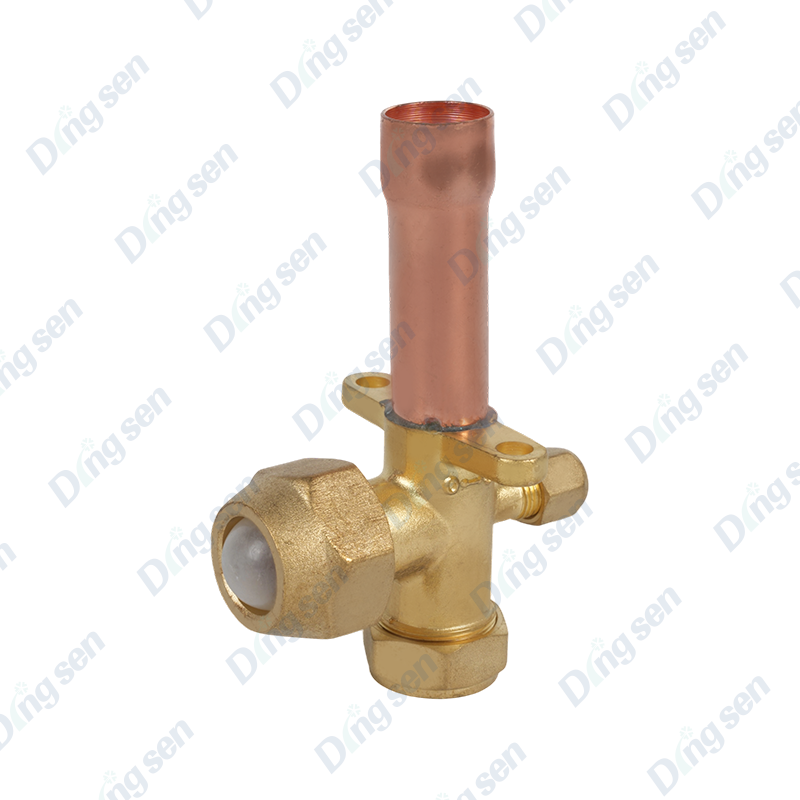

READ MORECylinder valve

Cylinder valves are the core control components of gas cylinders, used to precisely open and close gas output. They also provide pressure stabilization and leak prevention, ensuring safe gas storage and use.

Compatible with various gas cylinders, including oxygen, acetylene, and refrigerant, they meet the gas control needs of industrial, medical, and refrigeration applications.

Manufactured from high-strength alloys, they undergo pressure and seal testing to ensure reliable performance.

Service includes pre-sales selection and after-sales maintenance guidance. Advantages include precise volume control, excellent sealing, high-pressure resistance, and a wide range of compatibility.

Cylinder valves are the core control components of gas cylinder storage and delivery systems. Their core advantage lies in "safety control + multi-functional integration." Constructed from a single piece of high-strength alloy, they withstand long-term corrosion from gases like oxygen, acetylene, propane, and refrigerants. They also feature a precision pressure-stabilizing mechanism that stably regulates high-pressure gas within the cylinder to the required pressure for downstream equipment, preventing equipment damage or safety risks caused by sudden pressure fluctuations. A multi-layer sealing design (including corrosion-resistant gaskets and valve core sealing rings) eliminates gas leaks at the source. The valve core structure is optimized for different gas characteristics. For example, oxygen cylinder valves are oil-free, while acetylene cylinder valves are equipped with flashback arresters. Compatible gases include industrial gases, medical gases, refrigeration refrigerants, and specialty gases. Multiple connection methods, including threaded and flanged, are supported, accommodating cylinder interfaces from DN10 to DN50. Some models feature integrated flow metering for real-time monitoring of gas output. The operating end utilizes a non-slip handwheel or knob design, ensuring uniform opening and closing torque for precise control. Applications encompass a wide range of applications, including industrial manufacturing (e.g., oxygen/acetylene cylinders for welding and cutting), medical (e.g., medical oxygen cylinders), refrigeration (e.g., refrigerant cylinders), and laboratories (e.g., specialty gas cylinders). Whether in workshop production, hospital emergency response, or refrigerant refueling for refrigeration equipment, these valves provide safe and stable control for gas storage and transportation, making them a key component for ensuring safe gas use.

-

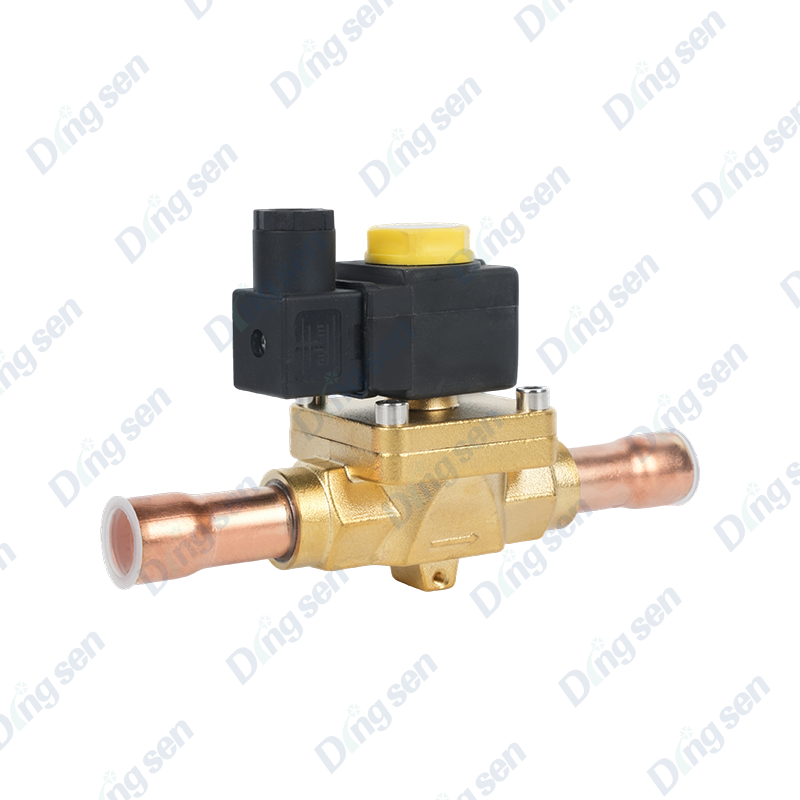

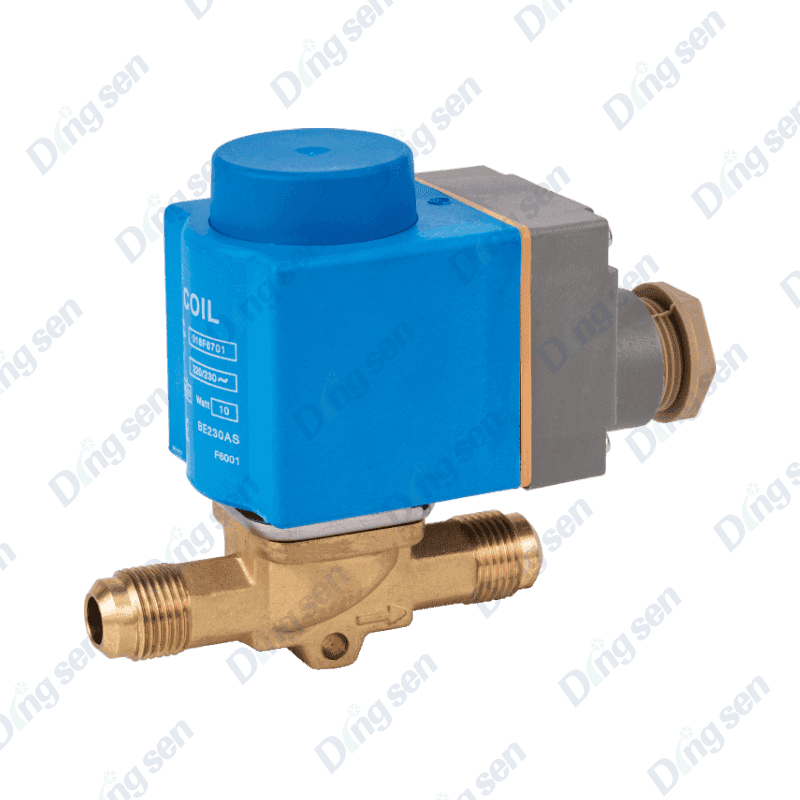

EVR solenoid valves are key components in refrigeration and air conditioning, co...

-

The air conditioning three-way valve is a key component for switching and contro...

-

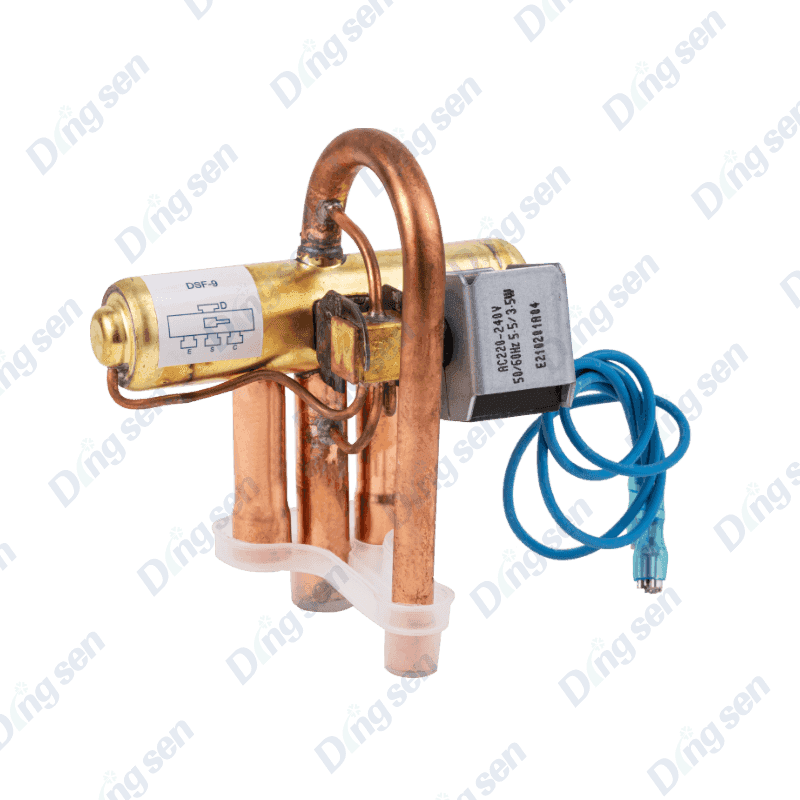

A four-way reversing valve is a key component for switching the flow of fluids (...

-

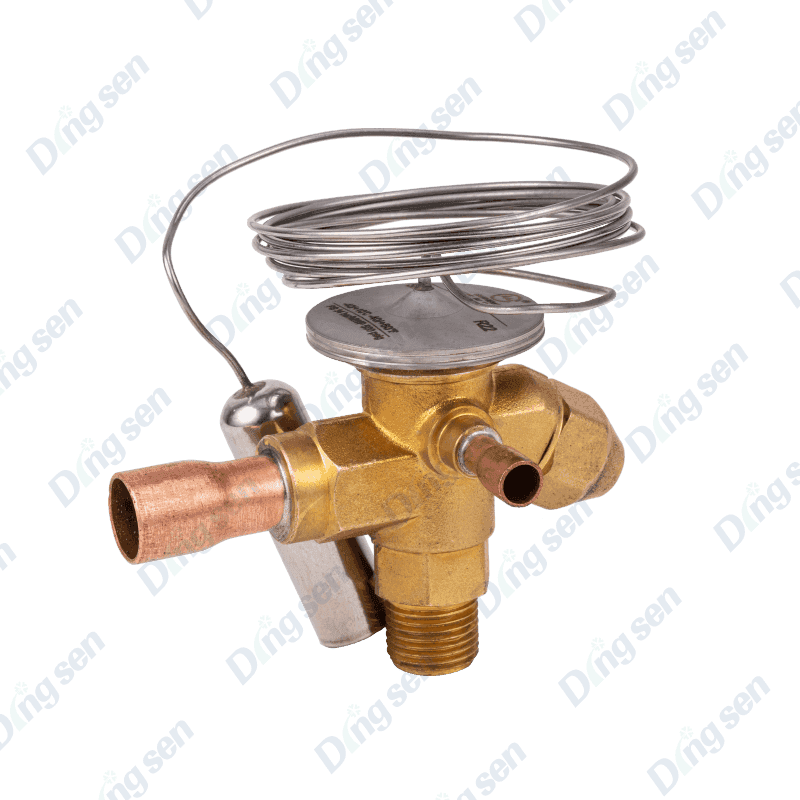

The thermal expansion valve features a compact body constructed of brass or stai...

-

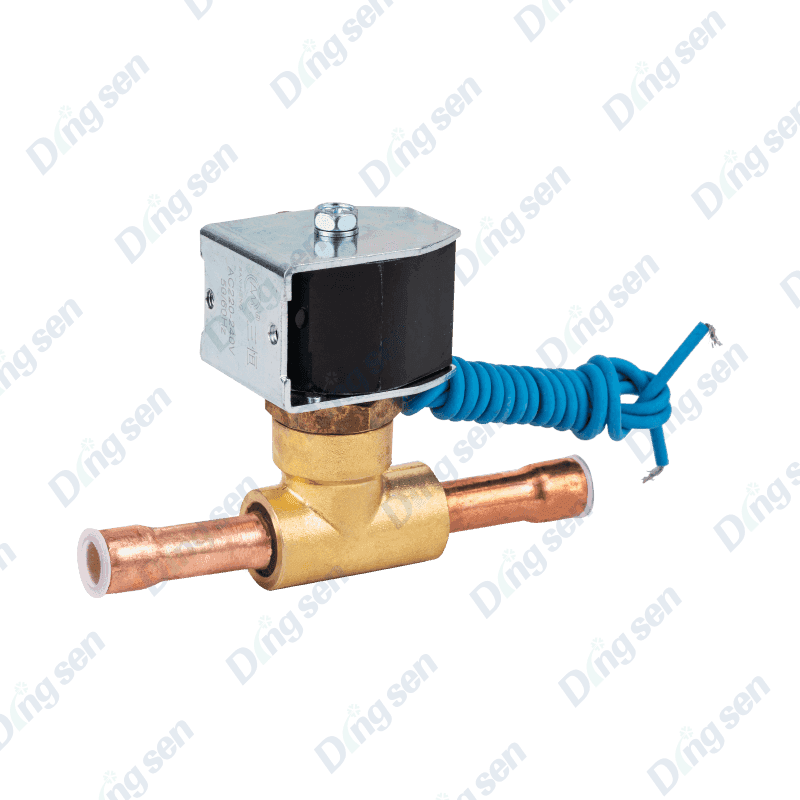

The FDF type solenoid valve is a highly reliable valve designed specifically for...

-

The EVR type solenoid valve features a split upper and lower structure, with a b...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى