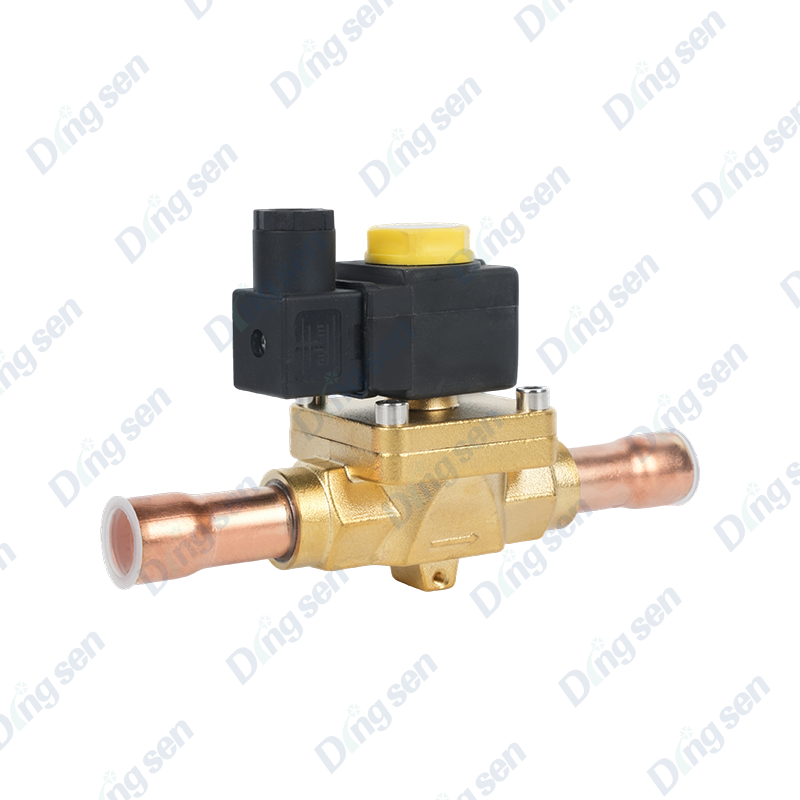

As a manufacturer specializing in high-quality copper fittings, we understand that the performance of air conditioning and refrigeration components directly determines the efficiency and lifespan of the entire system. Our copper fittings, with their excellent thermal conductivity and superior corrosion resistance, provide a reliable guarantee for your refrigeration projects.

Solid Foundation: Capacity, Quality, and Supply Chain Advantages

To ensure we can continuously provide the high-end market with a stable supply of high-quality copper fittings, we have built a strong operational foundation:

Stable Supply Guarantee and Quality Source: We have ample production capacity and strictly control the price, quality, and supply of raw materials. This rigorous supply chain management lays the most solid foundation for our continuous production of high-quality products.

Rapid and Efficient Operational Response: The company has deployed a comprehensive ERP system, available 24/7, ensuring rapid response and short response times to customer needs. Core processes can be completed within 15-30 minutes, greatly improving cooperation efficiency.

We focus on developing high-quality products for the high-end market. All our copper fittings strictly adhere to international standards, and our products are primarily exported to Europe, America, Japan, and other regions with extremely high quality requirements.

Superior Performance and Energy Efficiency:

We use high-purity copper as our core material to ensure optimal thermal conductivity, which directly impacts refrigeration efficiency and reduces system energy consumption. Choosing our copper pipes and fittings means choosing an energy-saving solution that meets international standards.

Exceptional Reliability and System Lifespan Guarantee:

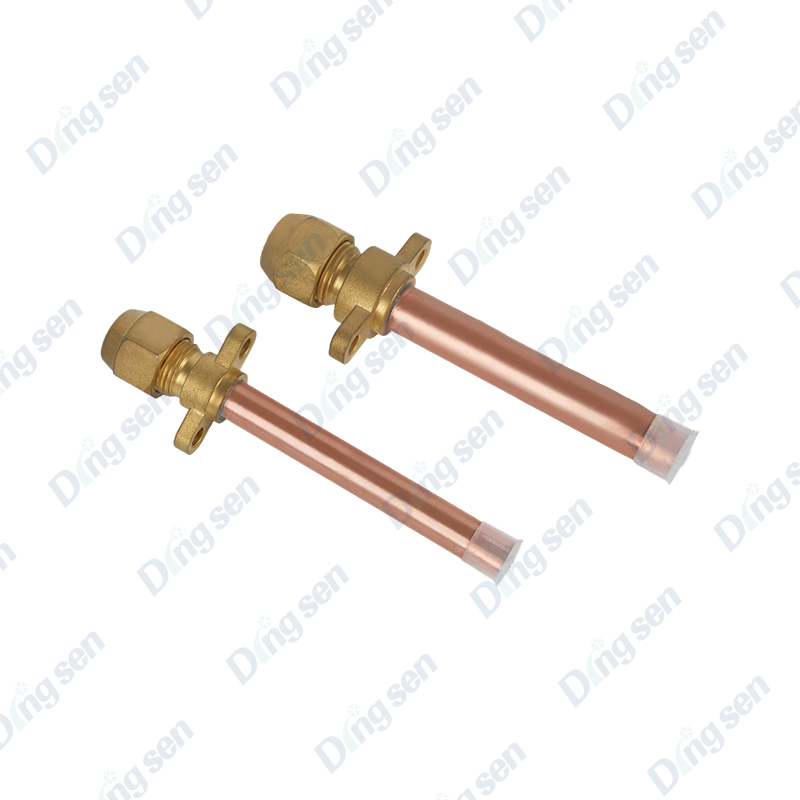

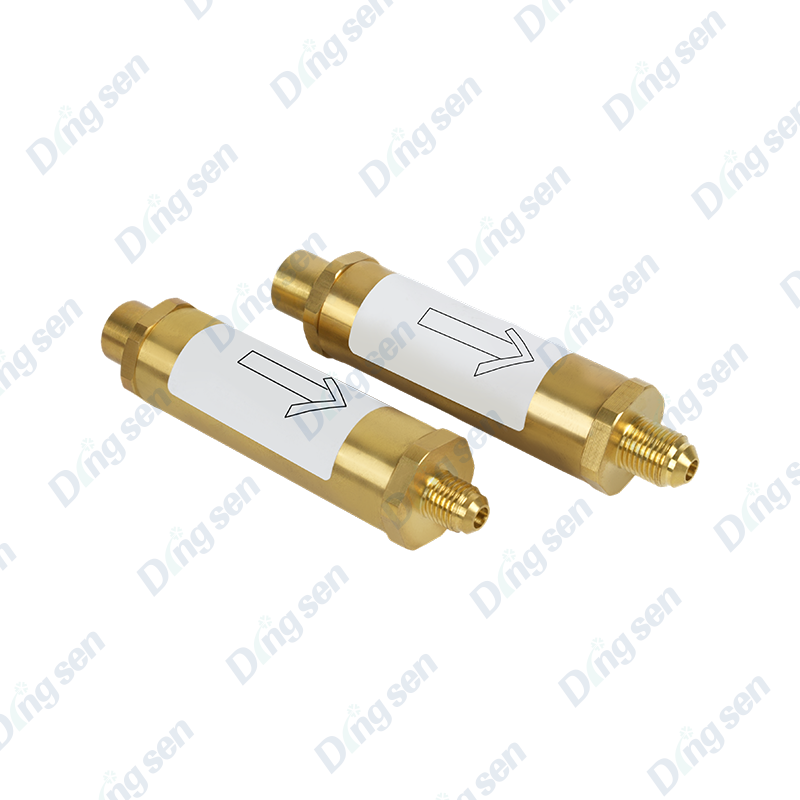

The corrosion resistance and high-pressure resistance of our copper fittings are crucial. Through sophisticated manufacturing processes, we ensure that our copper components can withstand long-term corrosion from the refrigerant and high-pressure environments within the system, guaranteeing system stability and extending the overall lifespan of the equipment.

Perfect Sealing and Airtightness of Connections:

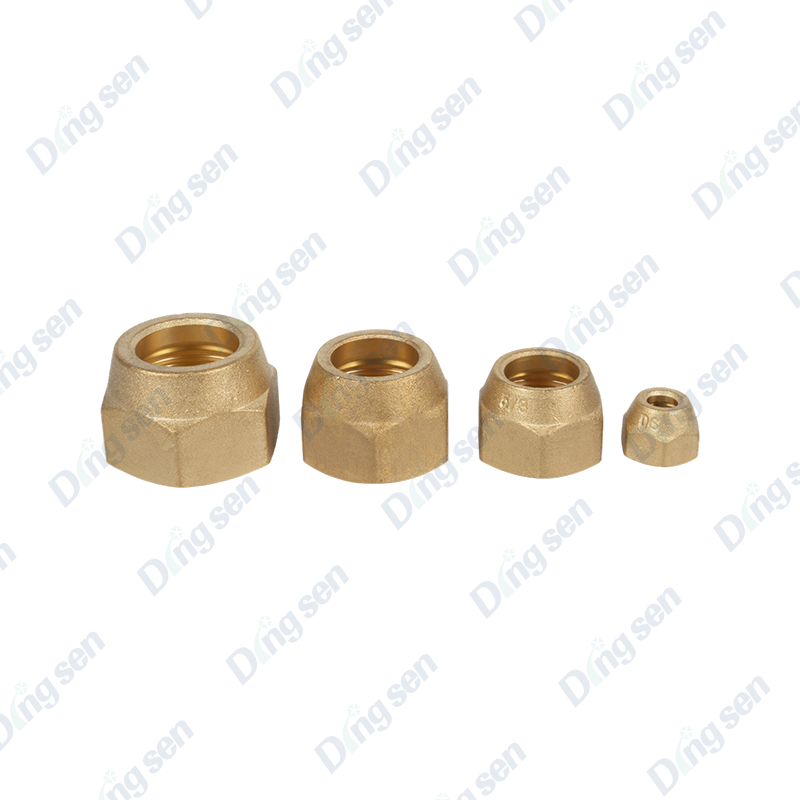

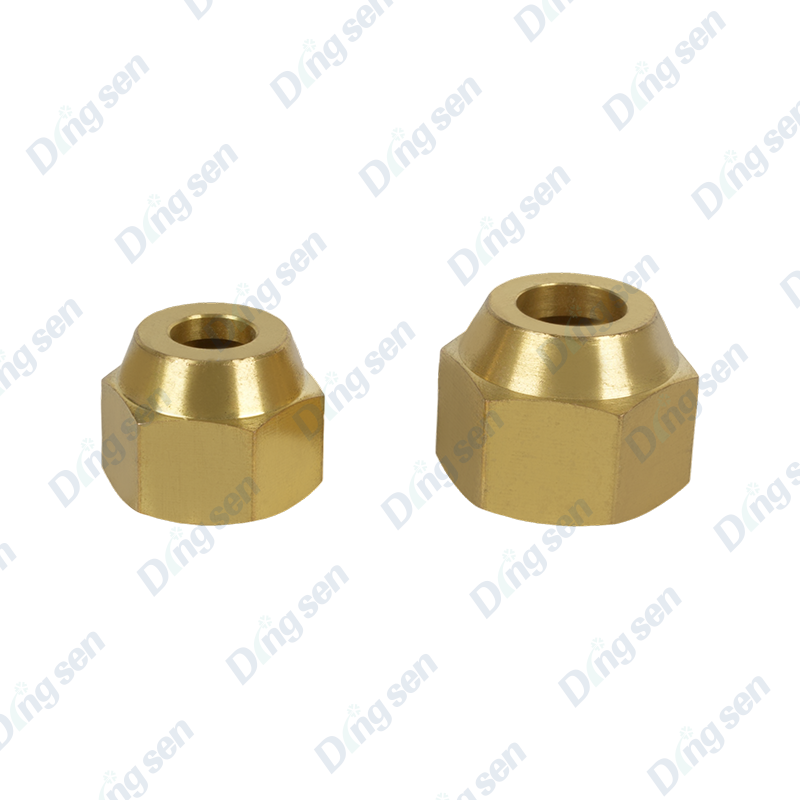

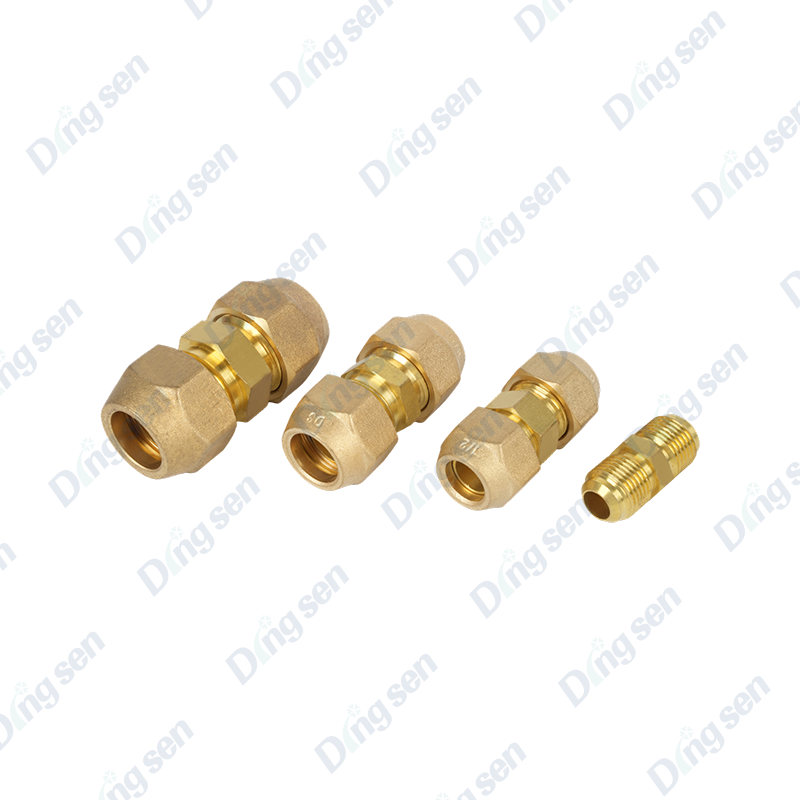

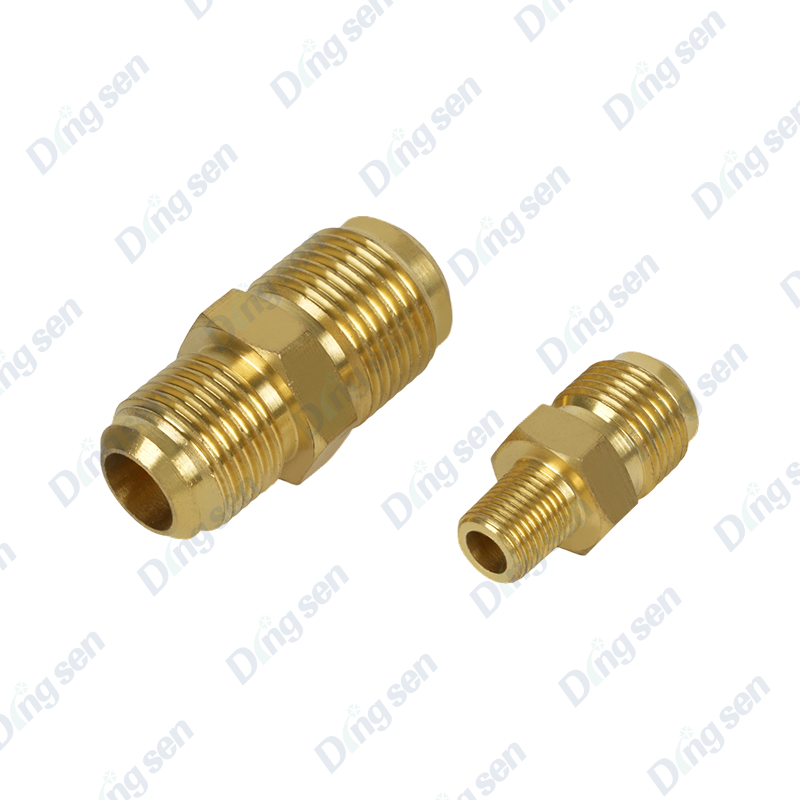

Airtightness is the lifeline for refrigeration piping. We use precision-machined fittings (such as copper tees and elbows) to ensure excellent weldability and achieve zero leakage. Precise tolerance control eliminates the risk of refrigerant leakage.

High-standard machining precision and surface finish:

We utilize CNC machining or precision extrusion technology to ensure that the dimensional accuracy and surface finish of every copper fitting reach leading levels, perfectly matching the installation requirements of various air conditioning accessories, including custom-made irregular-shaped copper fittings.

Choosing our copper fittings means gaining a partner with stable production capacity and efficient management, as well as high-quality copper fittings that are subject to strict raw material control and international standard certification, providing the most reliable guarantee for your high-end refrigeration projects.

en

en  Español

Español عربى

عربى