In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

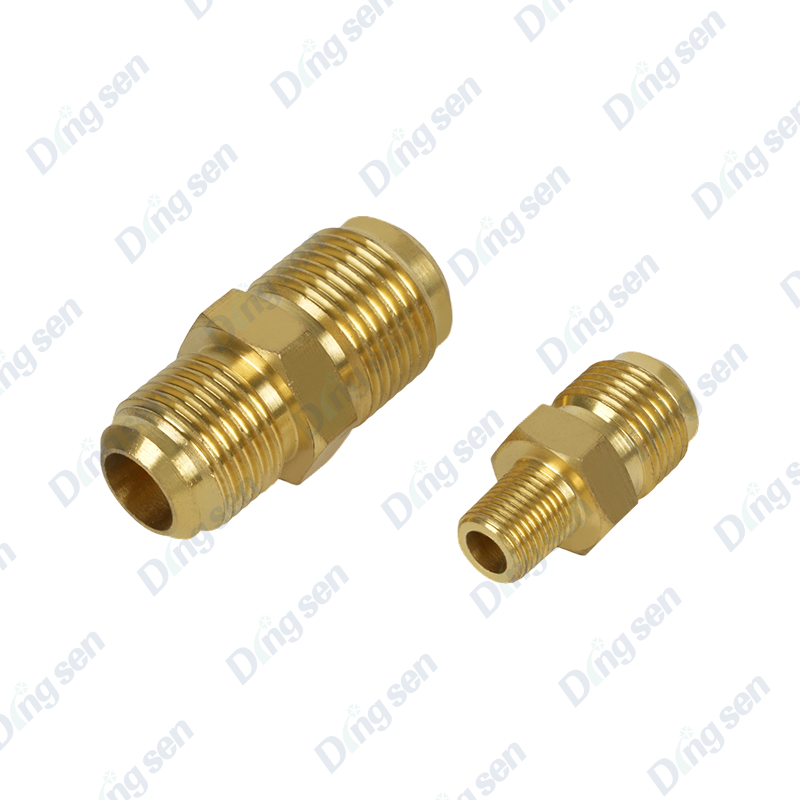

READ MOREAir conditioning copper pipe female-male connector

Air conditioning copper pipe female-male connector are core fittings for connecting male and female connectors on air conditioning piping. With a male connector on one end and a female connector on the other, they precisely connect copper tubes with different connector types, ensuring refrigerant transmission and preventing leaks.

They are suitable for connecting new and old air conditioning units, repairing pipes, and when connector types don't match.

Made of brass, precision-turned and seal-tested, they feature refrigerant-resistant sealing rings and are compatible with multiple refrigerants.

Our service includes selection guidance. Advantages include precise fit, excellent sealing, corrosion resistance, and easy installation. The air conditioning copper pipe male-to-female adapter is a key fitting for resolving interface mismatches in air conditioning piping systems. Its core advantages include "male-female compatibility" and long-lasting leak-proof sealing. Made of high-quality H62/H65 brass through cold heading, it features a male male connector and a female female connector. It accommodates copper pipes with various interface types. A refrigerant-resistant nitrile rubber seal is built into the inner wall, ensuring a tight fit around the copper pipe flare when tightened. The brass material offers excellent corrosion resistance and is suitable for air conditioning operating conditions ranging from -30°C to 120°C, preventing interface deformation or seal failure caused by temperature fluctuations. The product covers mainstream copper tube diameters from 6mm to 15.88mm and is compatible with various refrigerant systems, including R22, R410A, and R32. The male end features anti-slip knurling, while the female end features a hexagonal wrench slot, ensuring a secure grip and smooth operation during installation. Select models include connector markings to quickly distinguish between male and female ends, reducing misconnections. The sealing ring utilizes a one-piece vulcanization process, ensuring a tight fit against the inner wall of the connector to prevent loss. It complies with the connector standards of various domestic and international air conditioner brands. Applications include connecting old and new residential air conditioner units (e.g., connecting the female connector of an old unit to the male connector of a new one), repairing commercial central air conditioner piping (adapting damaged connectors to different connector types), adjusting pipe connectors during air conditioner relocation (where the original pipe type does not match the new installation location), and transitioning copper pipes with different connector specifications during engineering installations. This effectively resolves installation challenges caused by incompatible connector types while ensuring smooth and tight refrigerant transmission throughout the piping system, mitigating cooling efficiency losses and refrigerant leaks caused by improper connector fit.

-

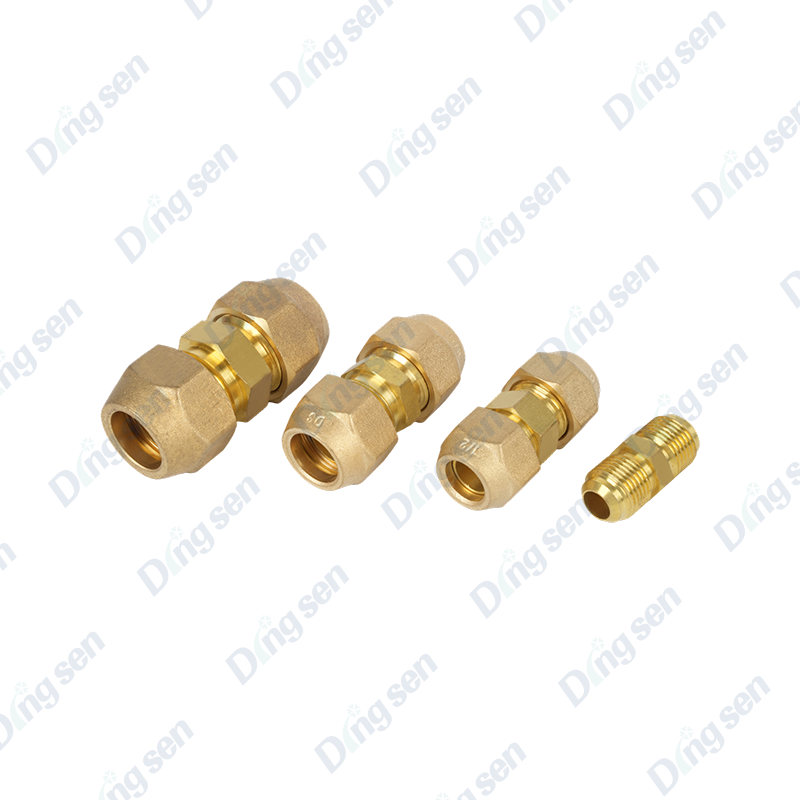

Air conditioning copper pipe duoble connector are core fittings for connecting t...

-

Air conditioning copper pipe reducing double joints are core fittings for connec...

-

Air conditioning pipe bandage strip is used to secure and protect the pipes conn...

-

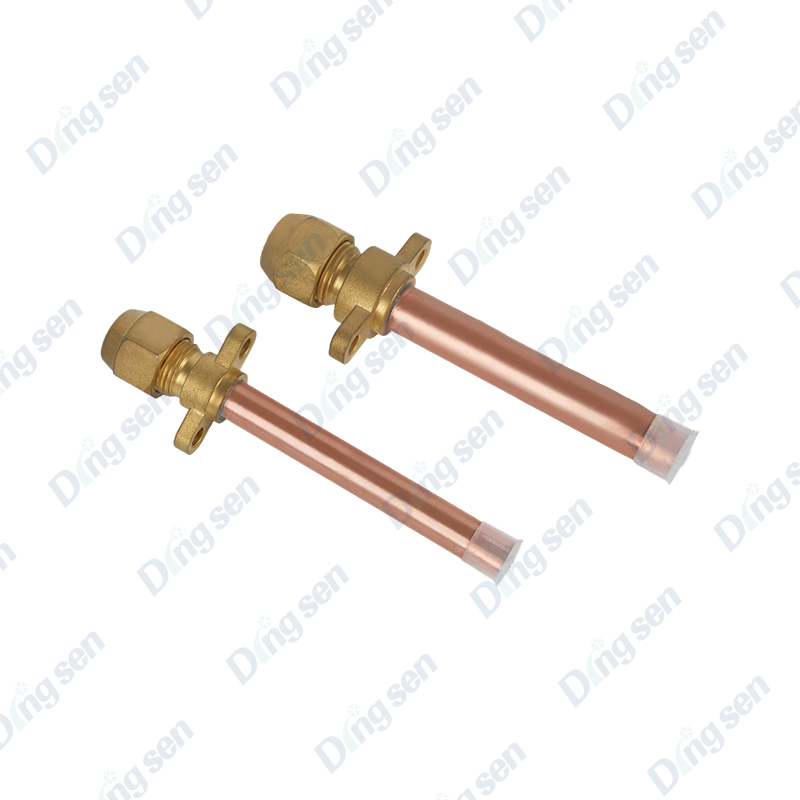

The hammerair conditioning copper pipe connector is a pipe connector designed sp...

-

The long air conditioning copper pipe connector is a metal connector designed sp...

-

The cup shaped air conditioning copper pipe connector is a high-performance acce...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى