In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

READ MOREOil-filled pressure gauge

Oil-filled pressure gauges are specialized pressure monitoring instruments. Built-in damping oil suppresses pointer jitter, ensuring accurate readings. They are suitable for pressure monitoring in refrigeration, hydraulic, and other systems, ensuring safe equipment operation.

They are suitable for pressure monitoring pipelines in air conditioners, refrigeration units, and hydraulic equipment, meeting measurement needs in various scenarios.

They are manufactured with a shock-resistant housing and high-precision movement, and undergo pressure calibration and vibration testing to ensure reliable performance.

Service includes pre-sales selection and after-sales calibration guidance. Advantages include accurate readings, strong shock resistance, a wide range of compatibility, and a long service life.

Oil-filled pressure gauges are high-precision pressure monitoring instruments specifically designed for industrial and refrigeration applications. Their core advantage lies in their built-in high-quality damping oil, which effectively suppresses pointer jitter caused by system pressure fluctuations and equipment vibration. This ensures stable and accurate readings under dynamic conditions, avoiding the reading errors caused by pointer jitter associated with traditional pressure gauges and providing reliable data support for system pressure monitoring. The gauge features a shock-resistant and pressure-resistant housing made of stainless steel or brass, withstanding operating temperatures ranging from -40°C to 80°C and high pressure environments (with a range of 0 to 60 MPa), making it suitable for use with corrosive media. Its built-in high-precision copper alloy movement, subjected to multiple rounds of pressure calibration and fatigue testing, boasts a service life 1.5 times that of conventional pressure gauges. Its dial features an anti-glare glass panel and clear graduations, with an optional luminous pointer for easy reading in dimly lit environments. It supports radial and axial mounting options to accommodate diverse piping layouts. Its wide range of applications includes pressure monitoring in refrigeration systems (air conditioners, refrigeration units, industrial refrigeration equipment), hydraulic systems (hydraulic machine tools, construction machinery), pneumatic systems, and pressure tanks. Whether testing refrigerant pressure in refrigeration systems, monitoring the operating pressure of hydraulic equipment, or maintaining pressure in industrial pipelines, it consistently performs, providing accurate pressure data for safe equipment operation and fault prediction, helping to reduce operational costs and safety risks.

-

The Air Conditioner Fluorine Filling Pressure Gauge is a dedicated instrument fo...

-

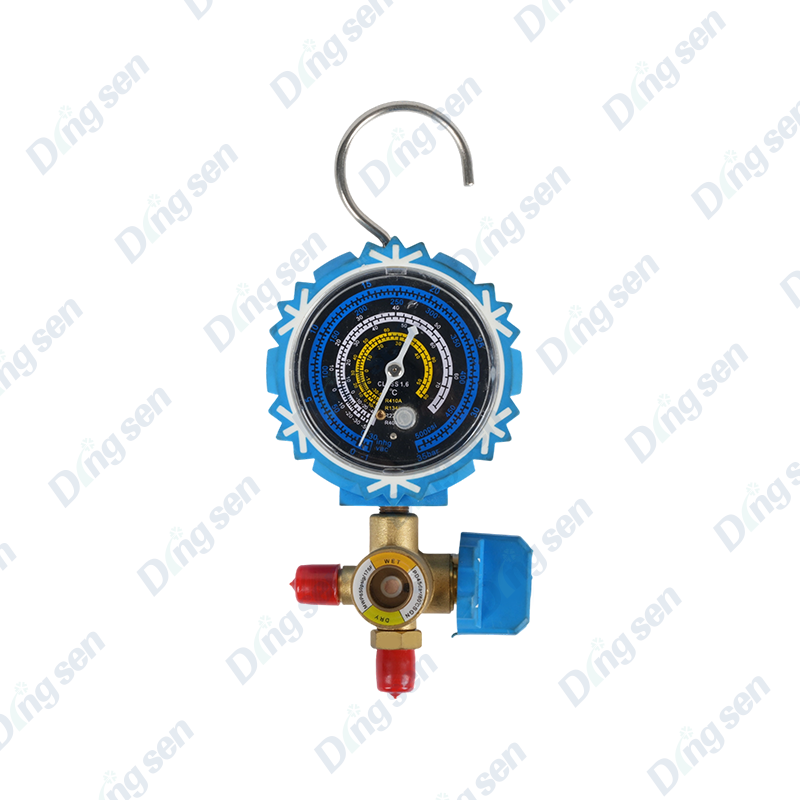

The refrigerant single gauge is a specialized instrument for refrigerant system ...

-

The Nitrogen Pressure Retention Kit is a pipeline leak testing tool set that inc...

-

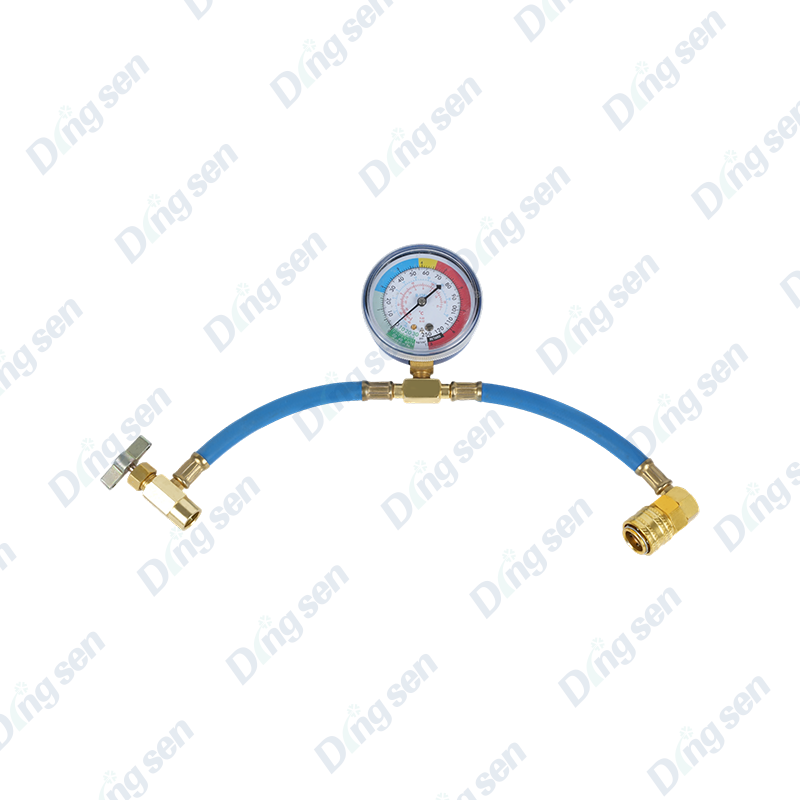

Pressure gauge automotive air conditioning filling system are designed specifica...

-

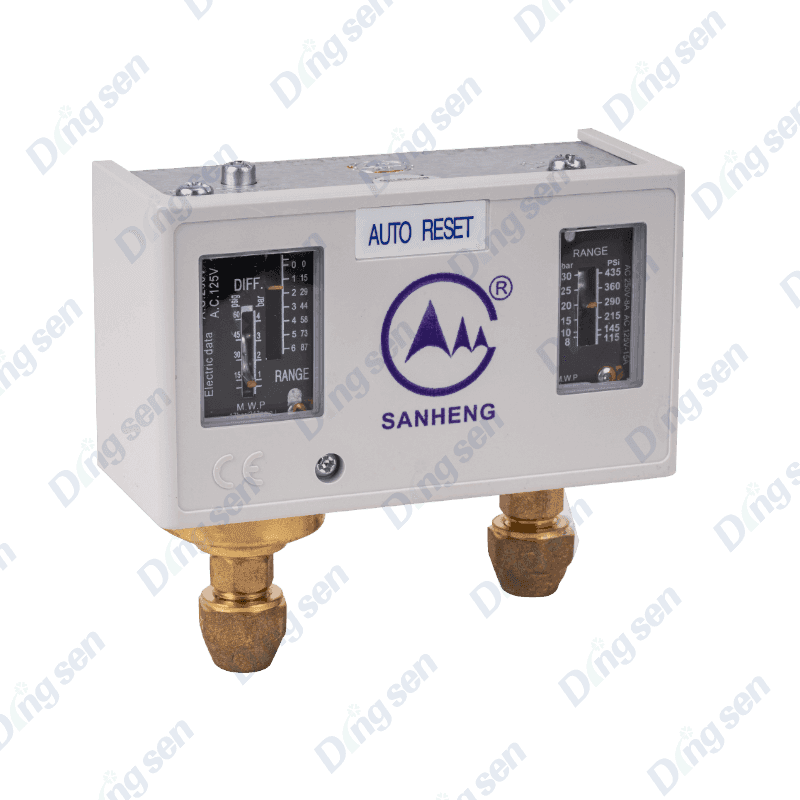

The refrigeration pressure controller features a rectangular box with a white, c...

-

Refrigerant and refrigeration oil filler is a special device for replenishing me...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى