In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

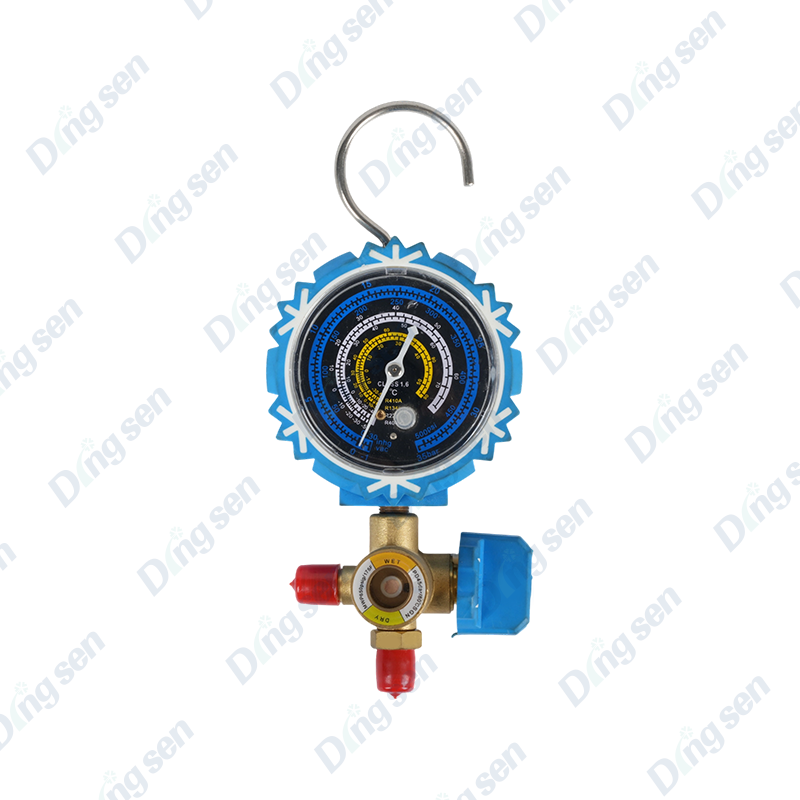

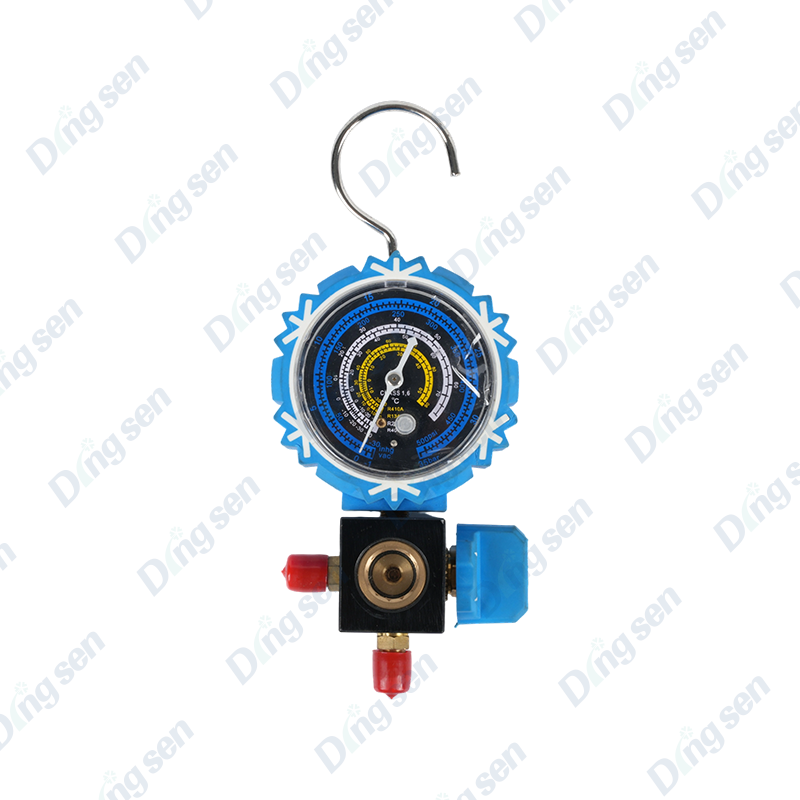

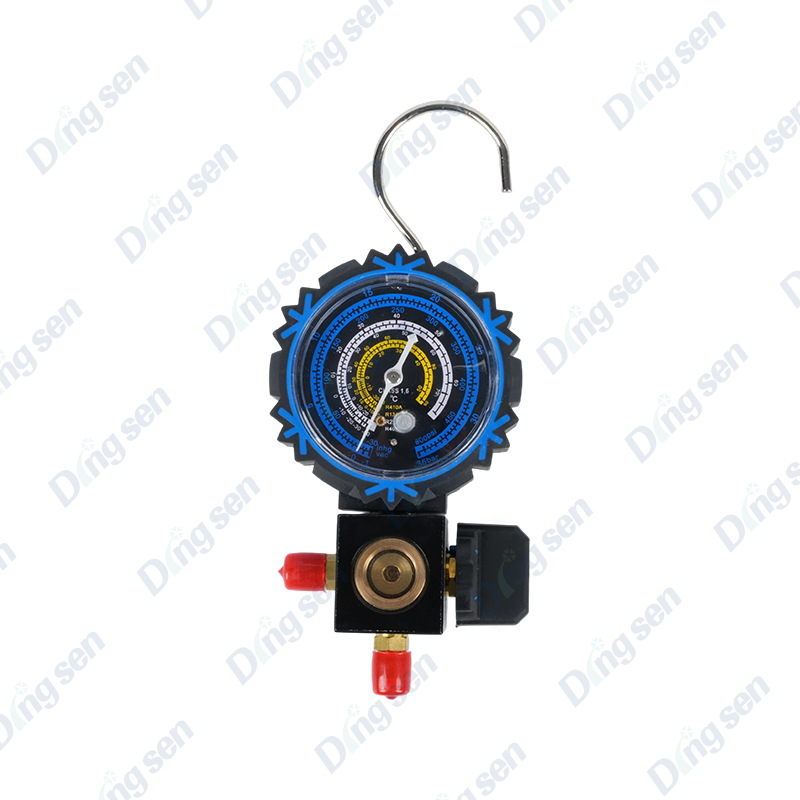

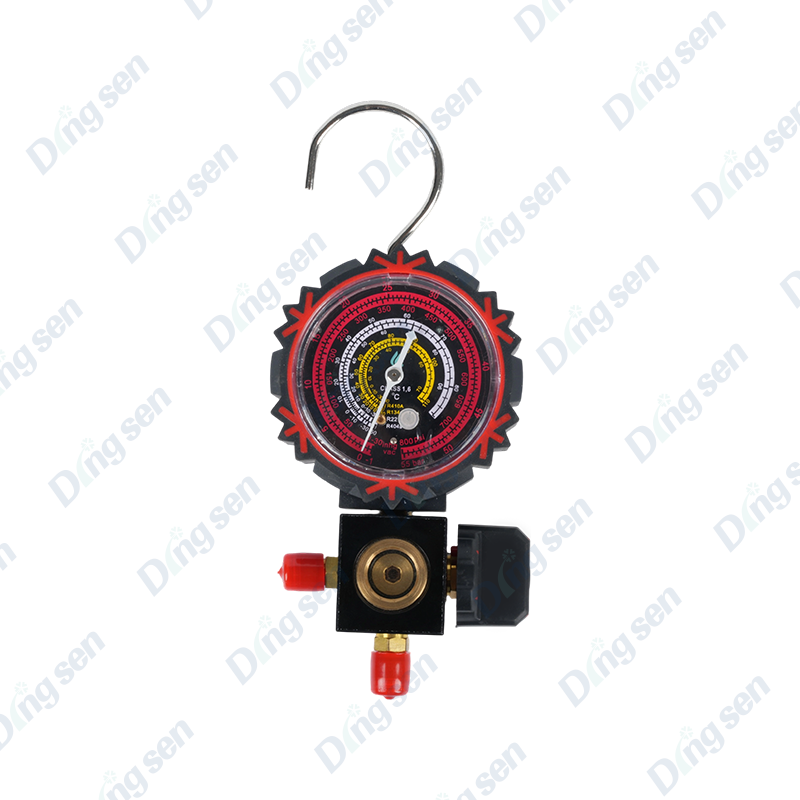

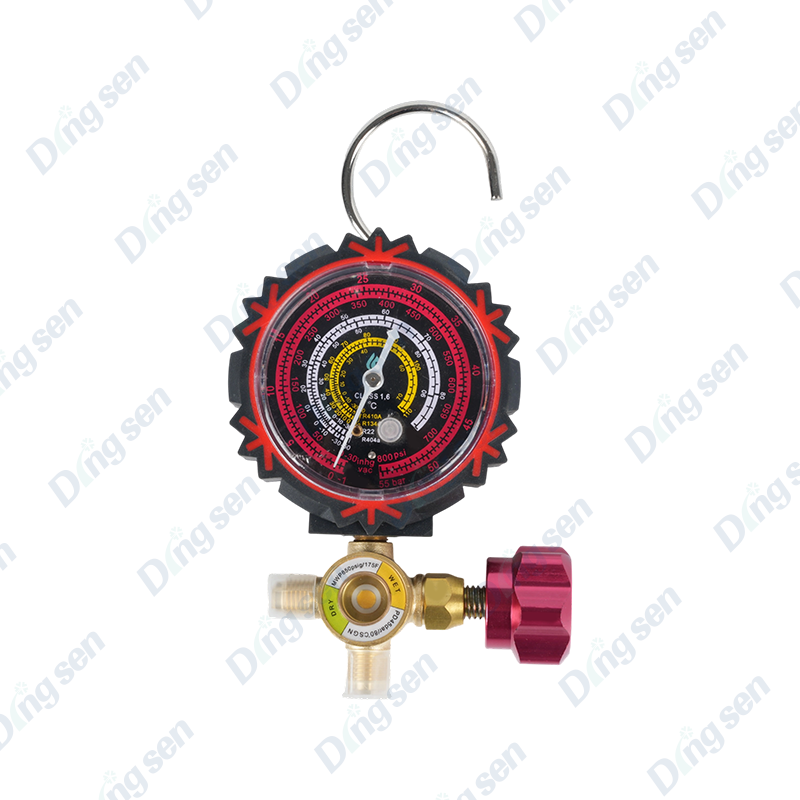

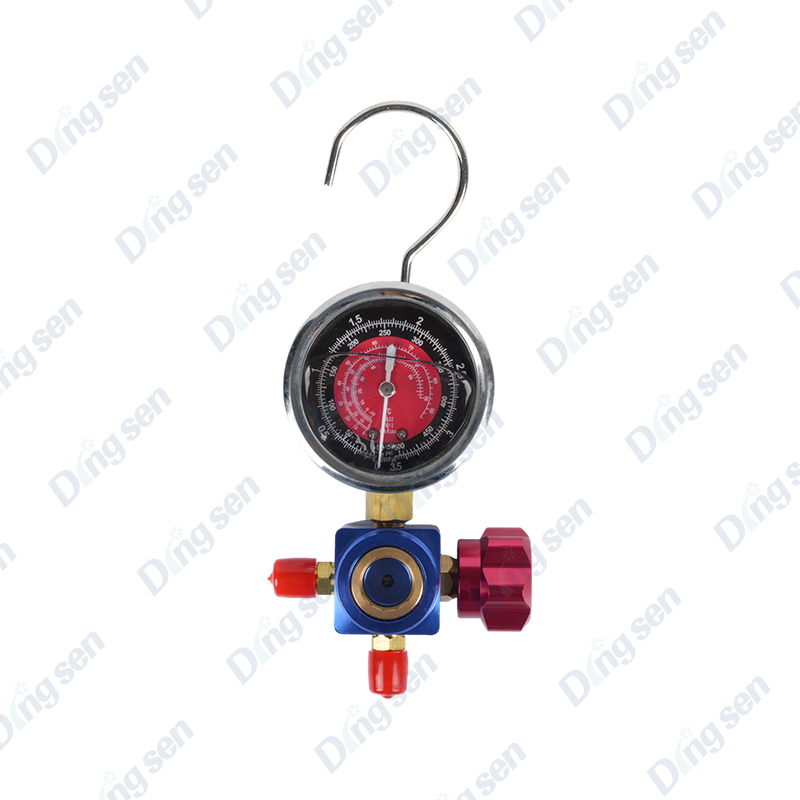

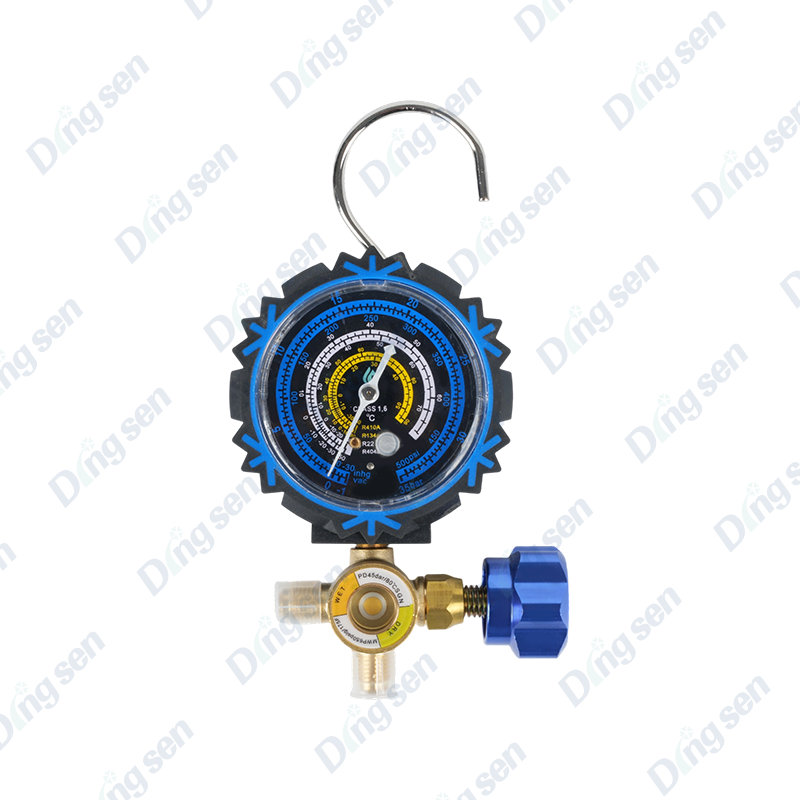

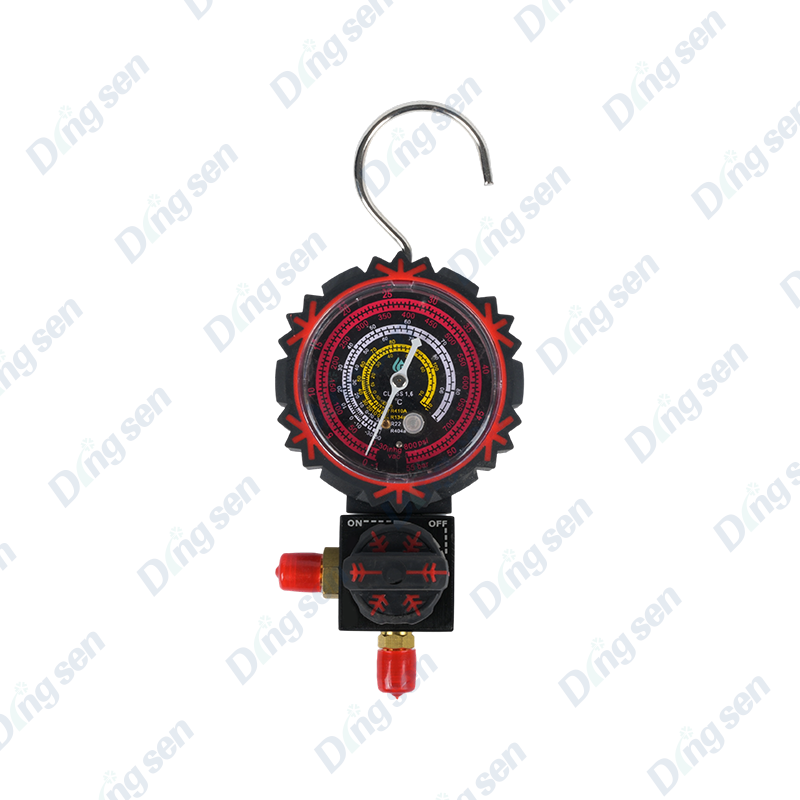

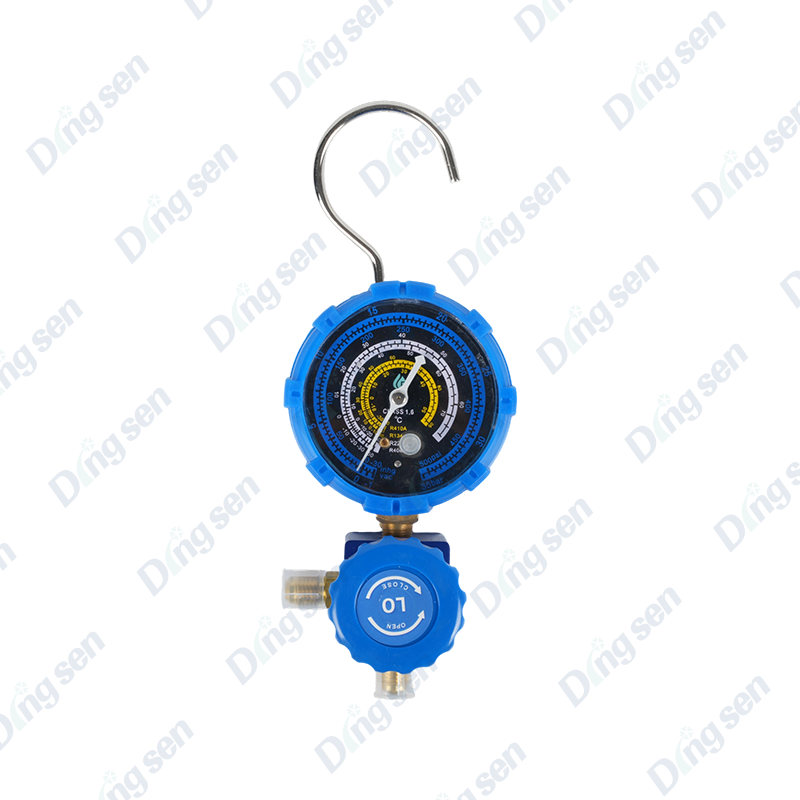

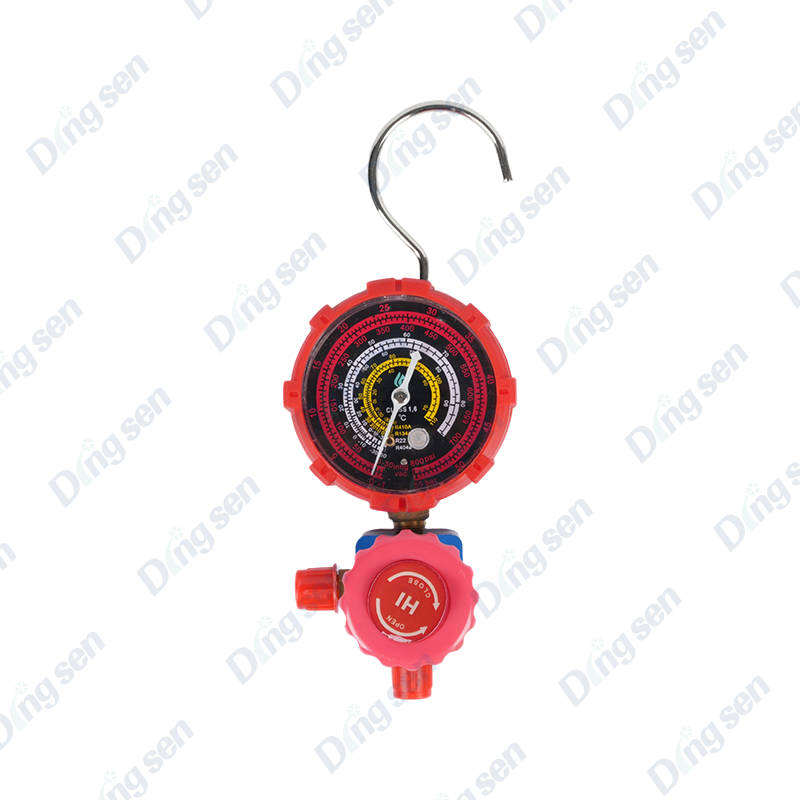

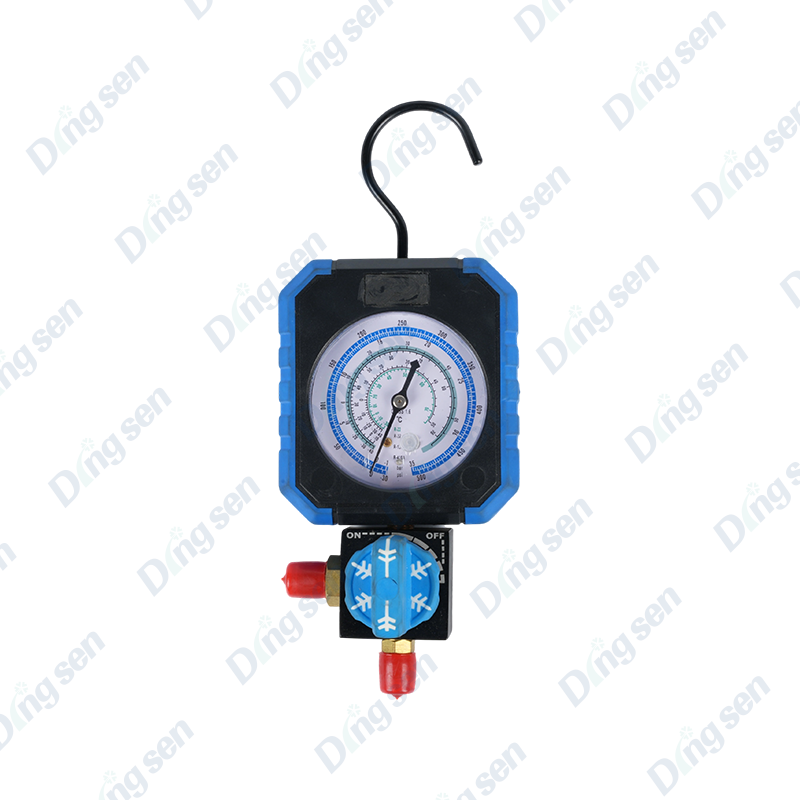

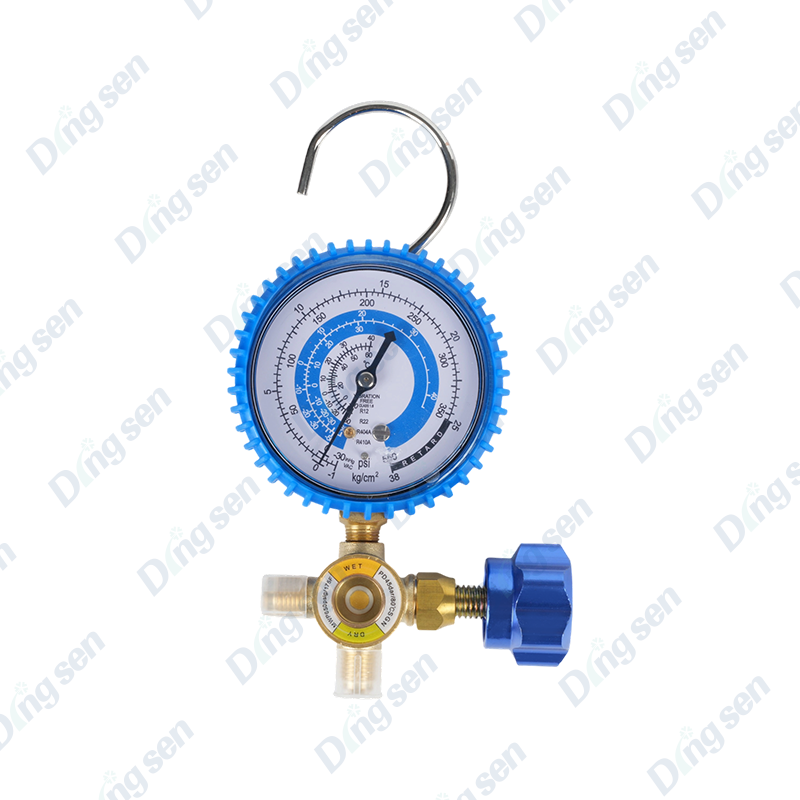

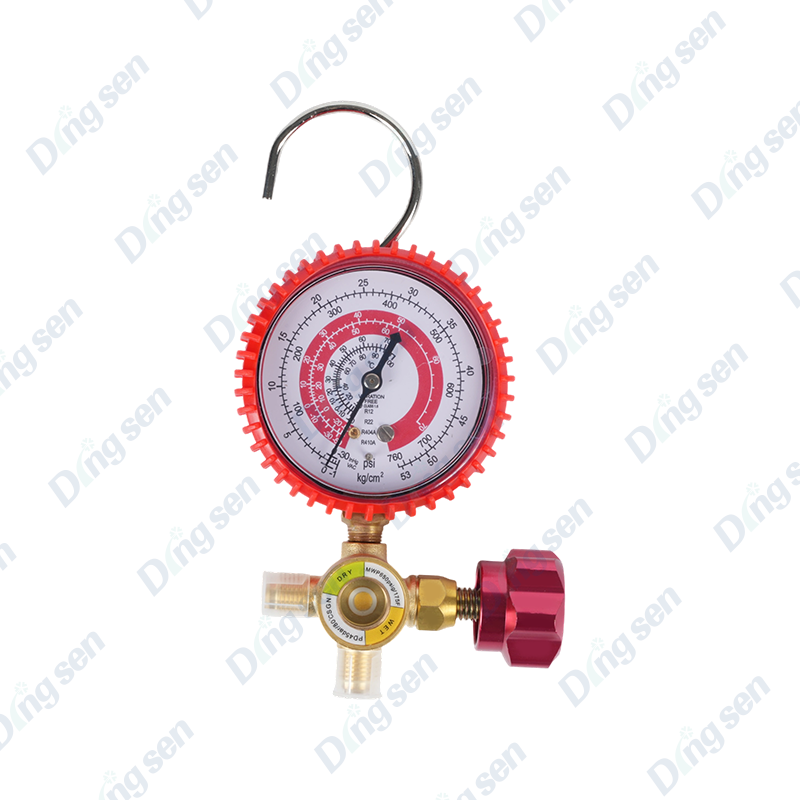

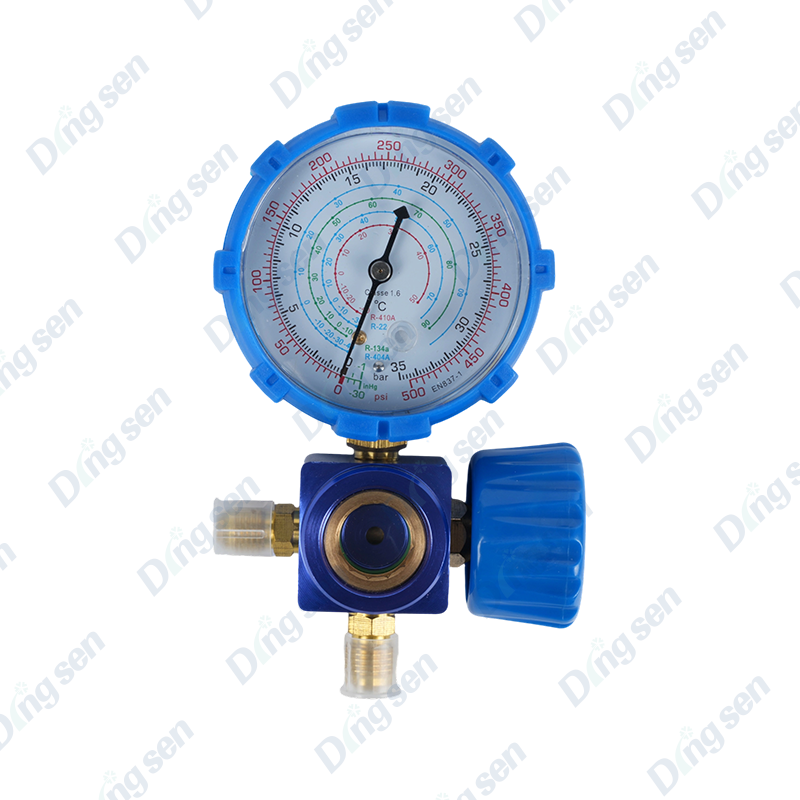

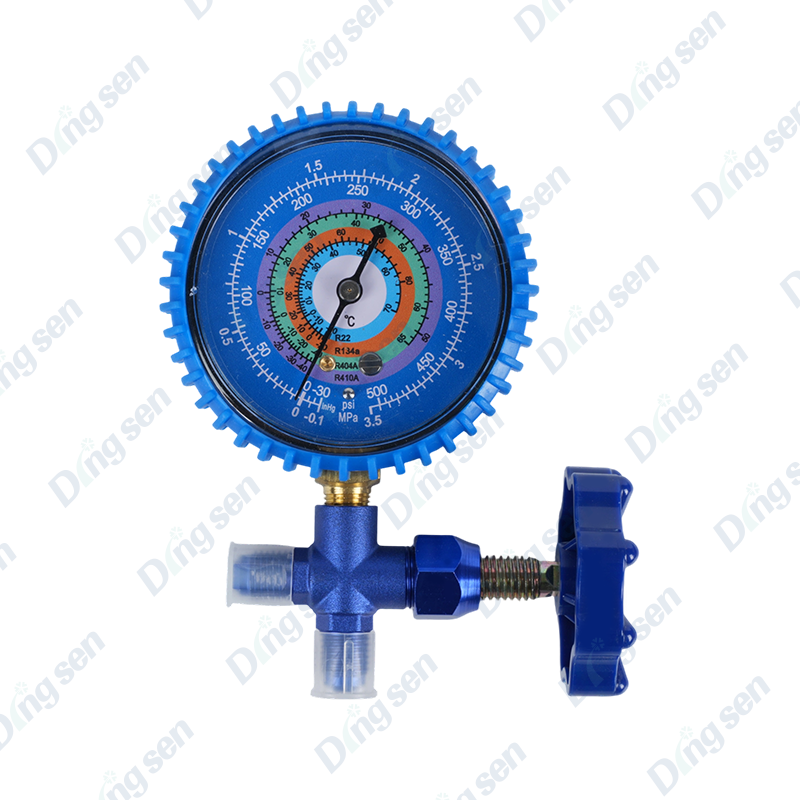

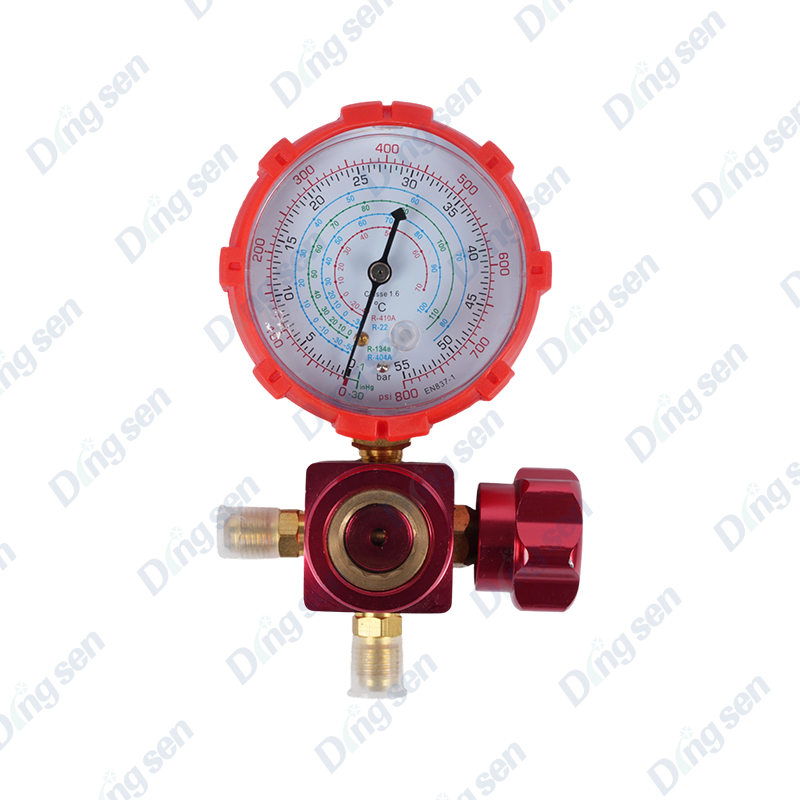

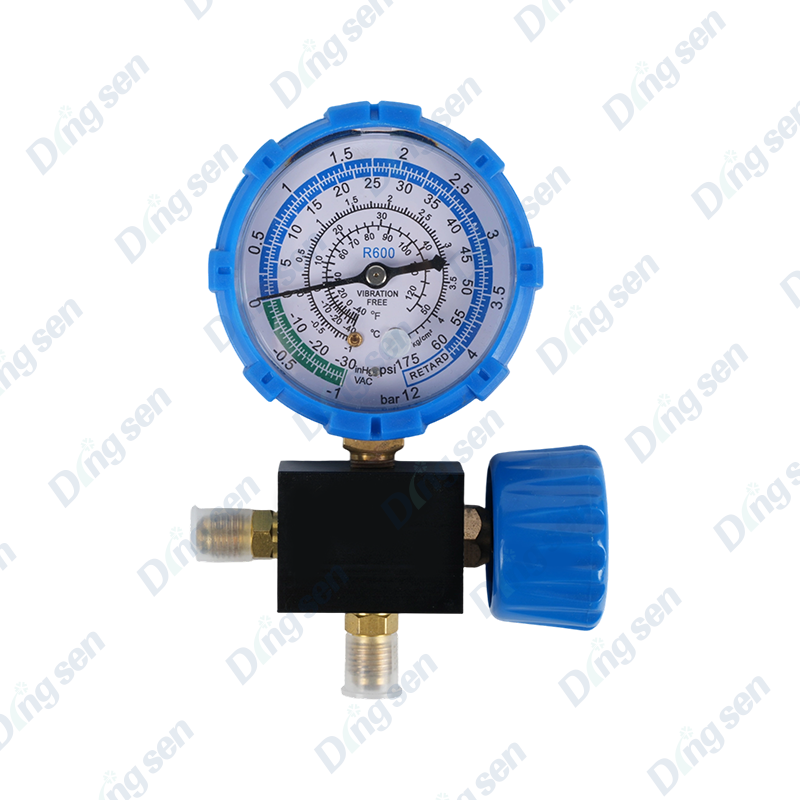

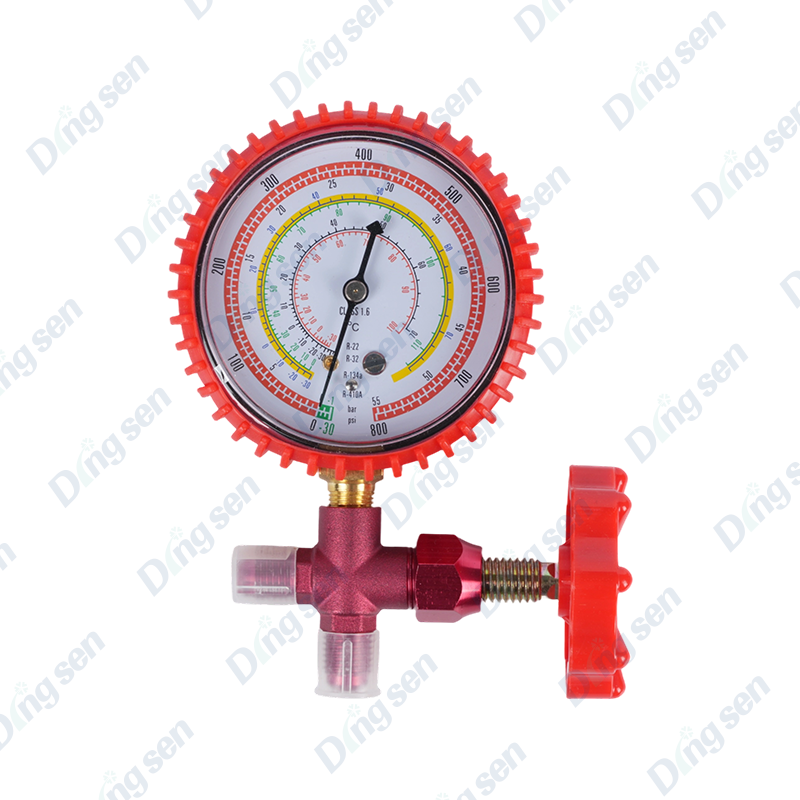

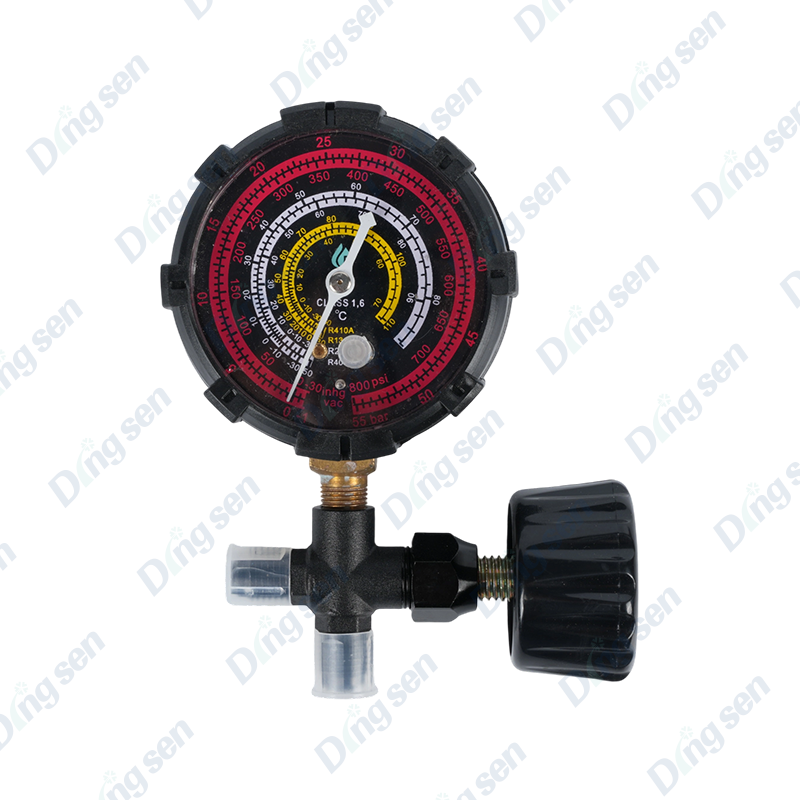

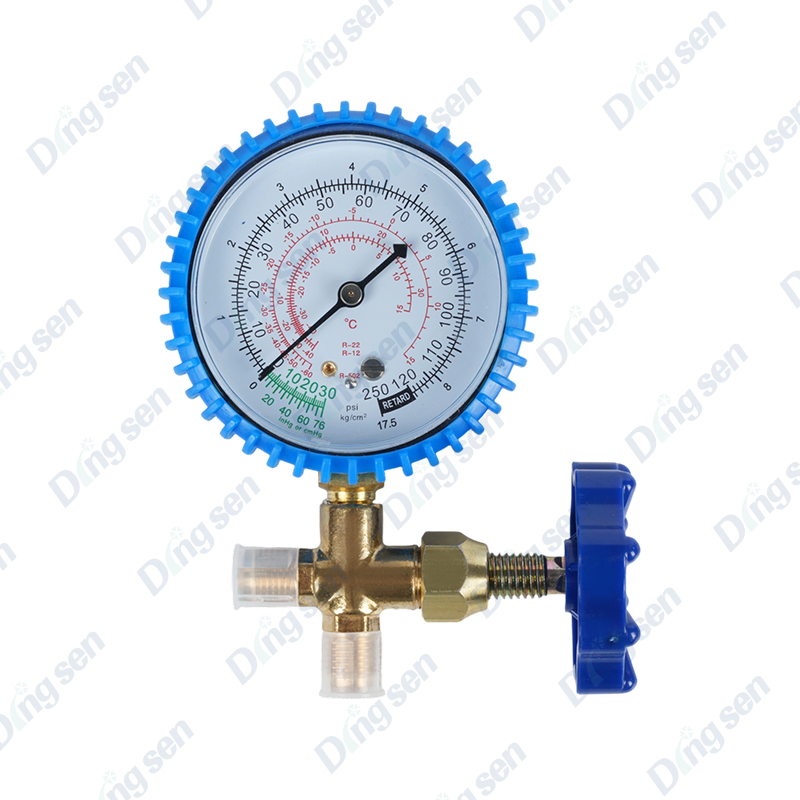

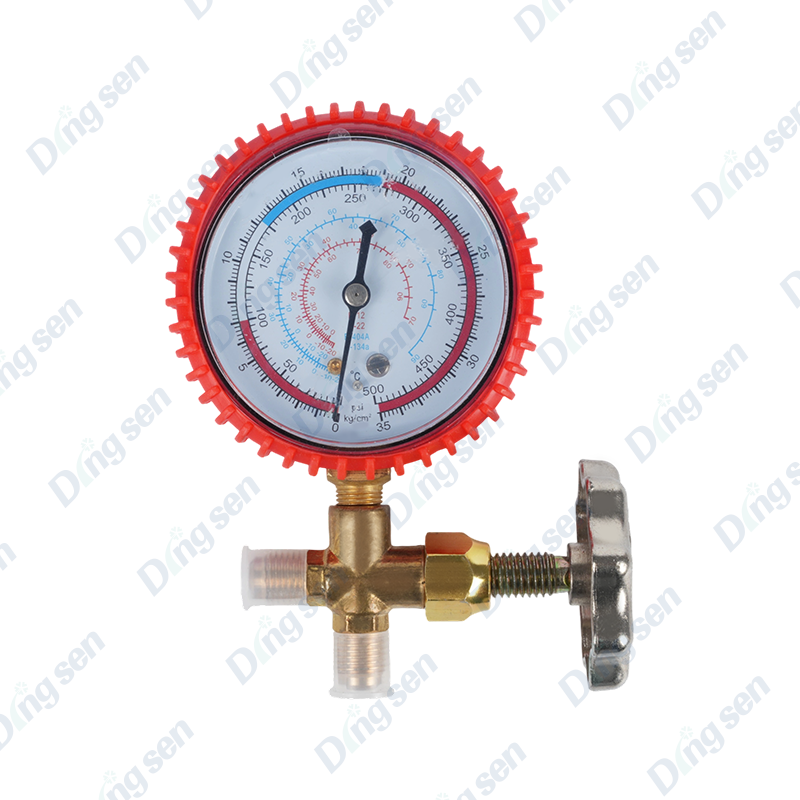

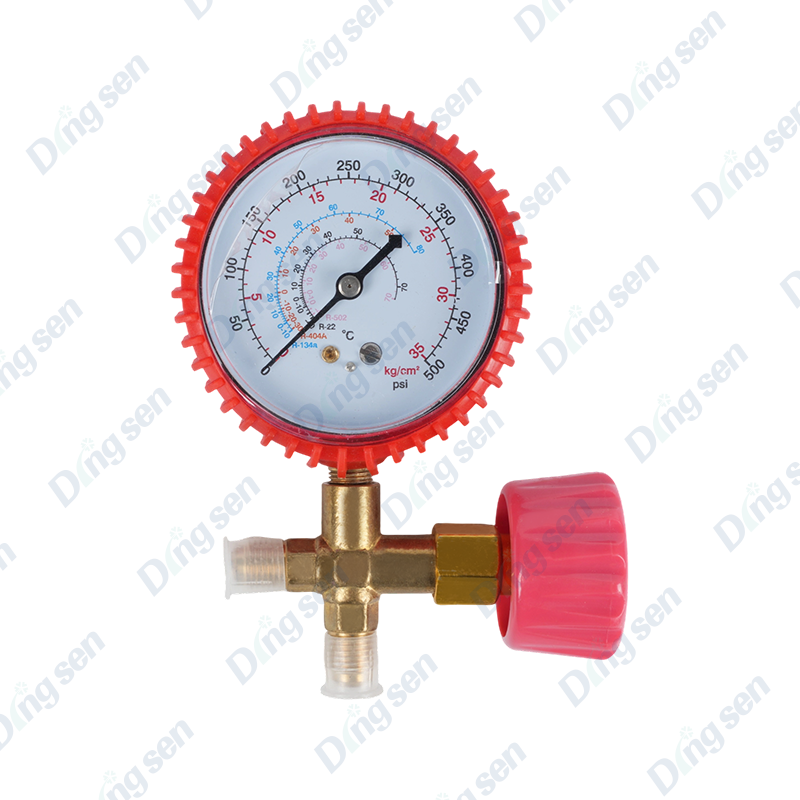

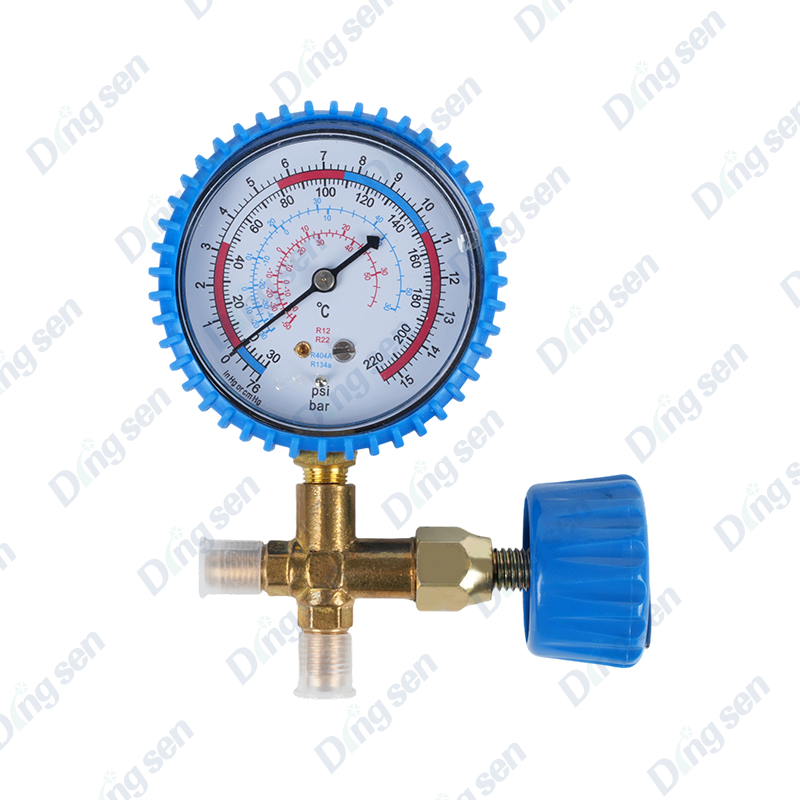

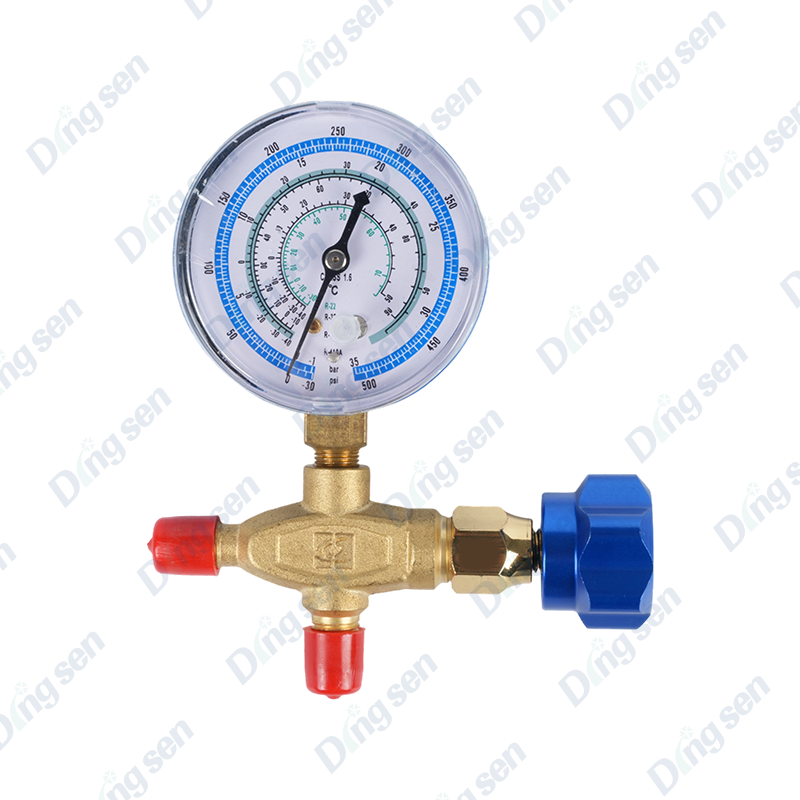

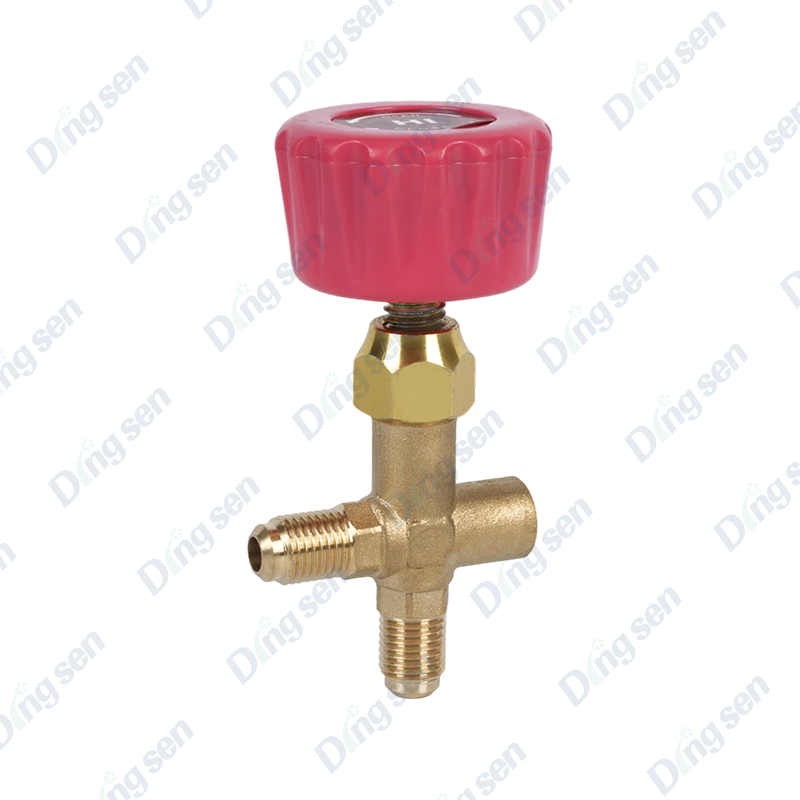

READ MORERefrigerant single gauge

The refrigerant single gauge is a specialized instrument for refrigerant system pressure monitoring. It accurately monitors single-line pressure, assists in determining refrigerant charge and system leaks, and ensures equipment cooling efficiency.

It is suitable for refrigerant systems such as air conditioners, refrigeration units, and automotive air conditioners, meeting repair, maintenance, and testing needs.

It is manufactured with a corrosion-resistant housing and high-precision movement, and undergoes pressure calibration and leak testing to ensure reliable performance.

Our service includes pre-sales selection and after-sales calibration guidance. Advantages include accurate readings, wide compatibility, ease of operation, and durability. The refrigerant meter is a precision instrument designed specifically for refrigerant system pressure monitoring. Its core advantages lie in its high accuracy and adaptability. Built with a high-precision copper alloy movement and sensitive pressure-sensing elements, it provides real-time and stable pressure monitoring of a single refrigerant system line (high-pressure or low-pressure side). Combined with the temperature-pressure curves for mainstream refrigerants (R22, R410A, R32, R134a, etc.) indicated on the dial, it can quickly assist in determining whether the refrigerant charge meets the required level and whether there are any leaks in the system. This provides accurate data support for refrigerant system maintenance and repair, preventing equipment failures caused by misjudgment of pressure. The housing is made of corrosion-resistant stainless steel or high-strength brass, and the surface has been treated with anti-oxidation to withstand a wide operating temperature range of -30°C to 70°C and corrosion from the refrigerant medium. The dial is equipped with an anti-glare tempered glass panel, with clear scales and pressure units marked. Some models include luminous hands for clear readings even in dim environments. The interface adopts a standardized quick-connect design, which is compatible with most refrigerant system connectors on the market and can be quickly connected without the need for additional adapters, making operation convenient. At the same time, a built-in overpressure protection structure automatically buffers when the pressure exceeds the range to prevent damage to the instrument. Application scenarios cover a wide range of refrigerant systems, including household/commercial air conditioners, industrial refrigeration units, automotive air conditioners, and refrigeration equipment. Whether it is fault detection by professional maintenance agencies, regular maintenance of corporate equipment, or simple maintenance by individual users, it can effectively play a role in pressure monitoring, helping to improve the efficiency and accuracy of refrigerant system operation and maintenance, and ensure stable equipment operation.

-

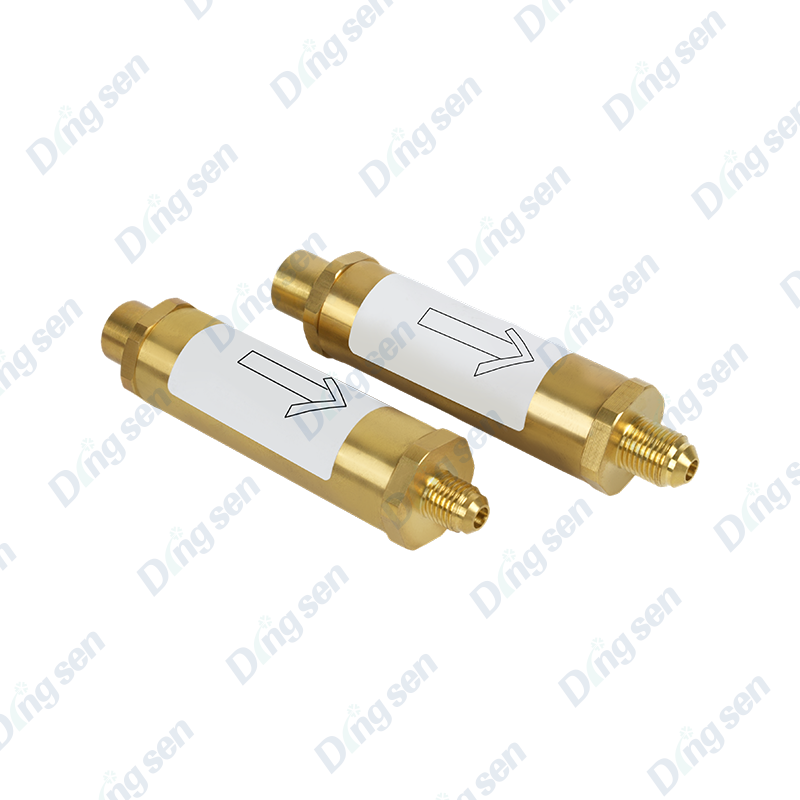

The refrigerant gas-liquid separator is a core separation component in refrigera...

-

Refrigerant and refrigeration oil filler is a special device for replenishing me...

-

Refrigerant vaporizer are key components in refrigeration systems, rapidly atomi...

-

The Refrigerant rapid injection pump automotive air conditioning filling system ...

-

The refrigerant leak detector is a specialized device for detecting leaks in ref...

-

The Air Conditioner Fluorine Filling Pressure Gauge is a dedicated instrument fo...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

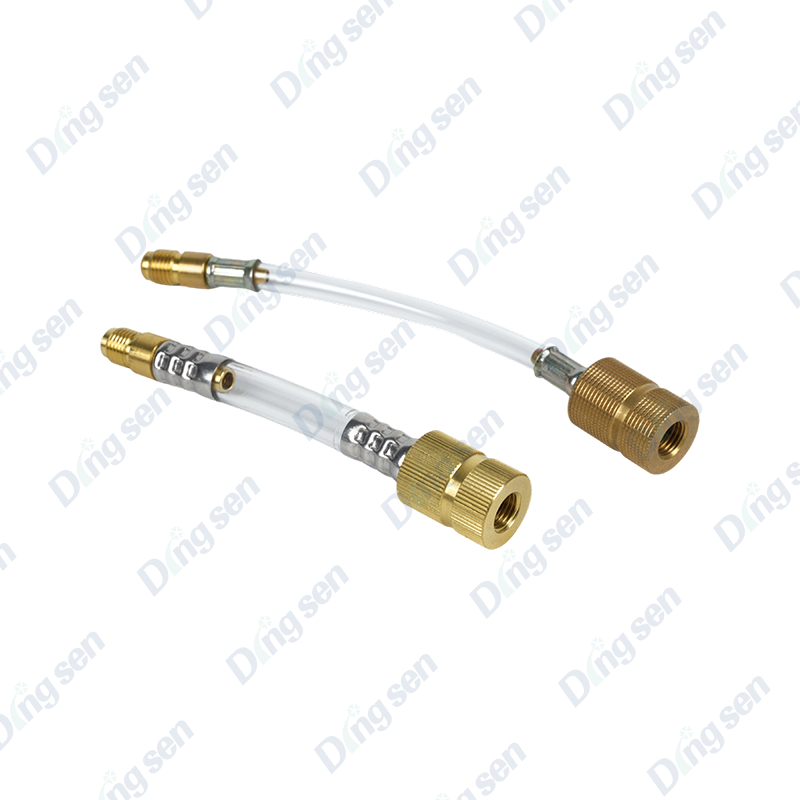

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى