In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

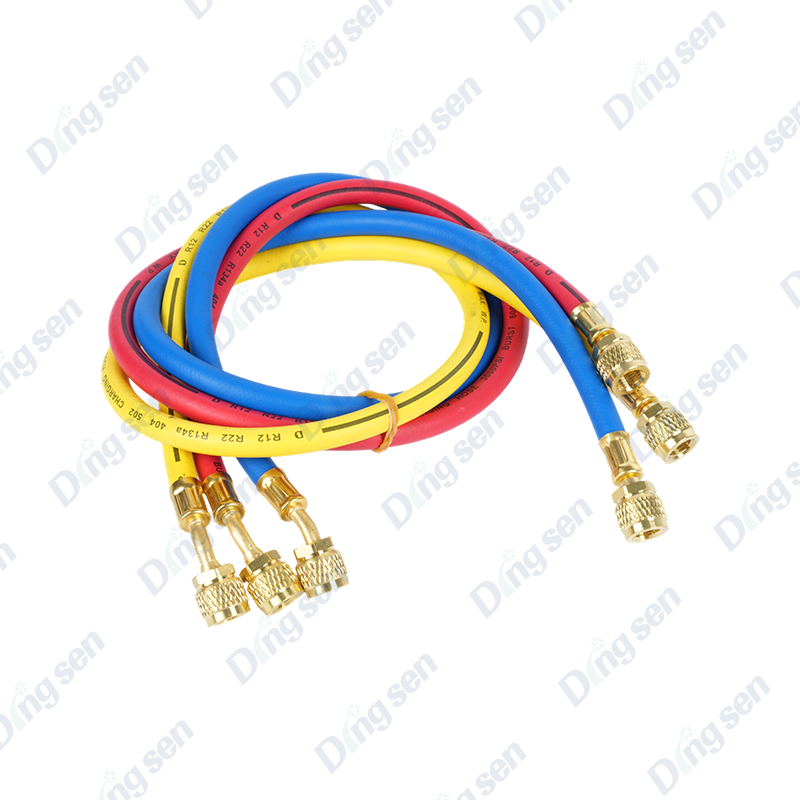

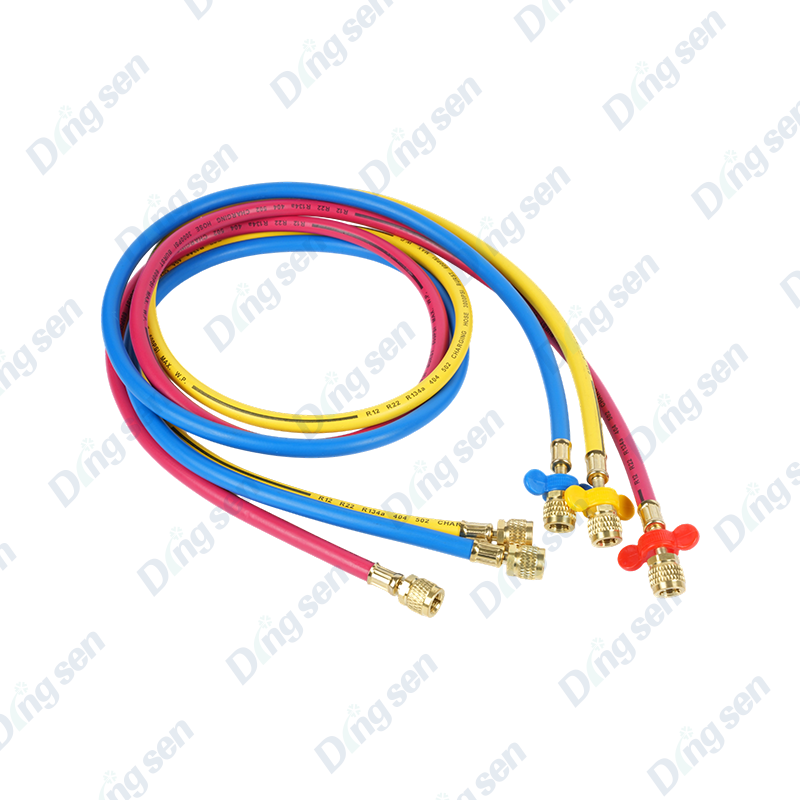

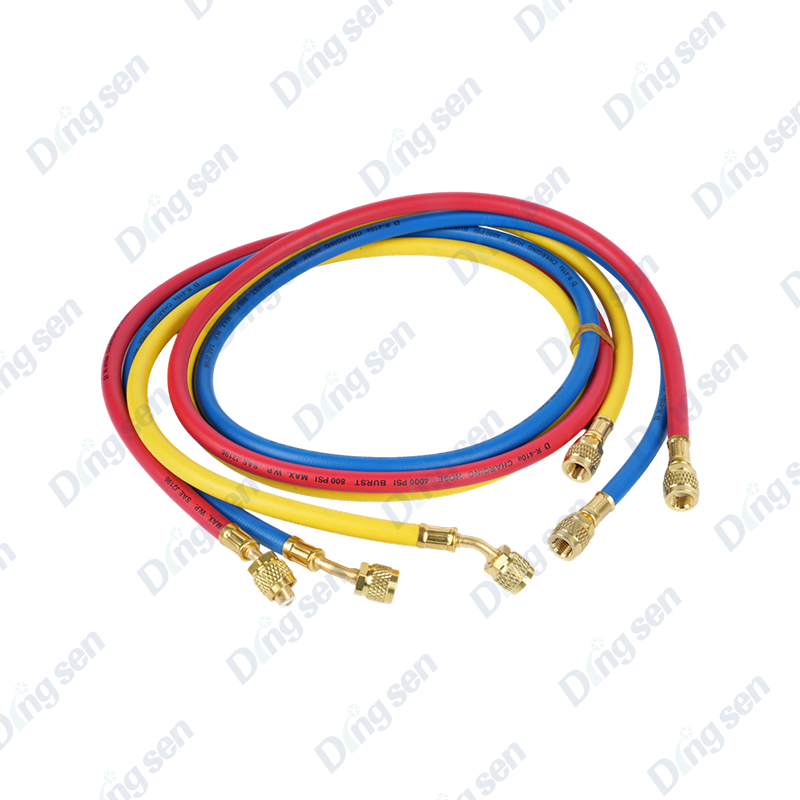

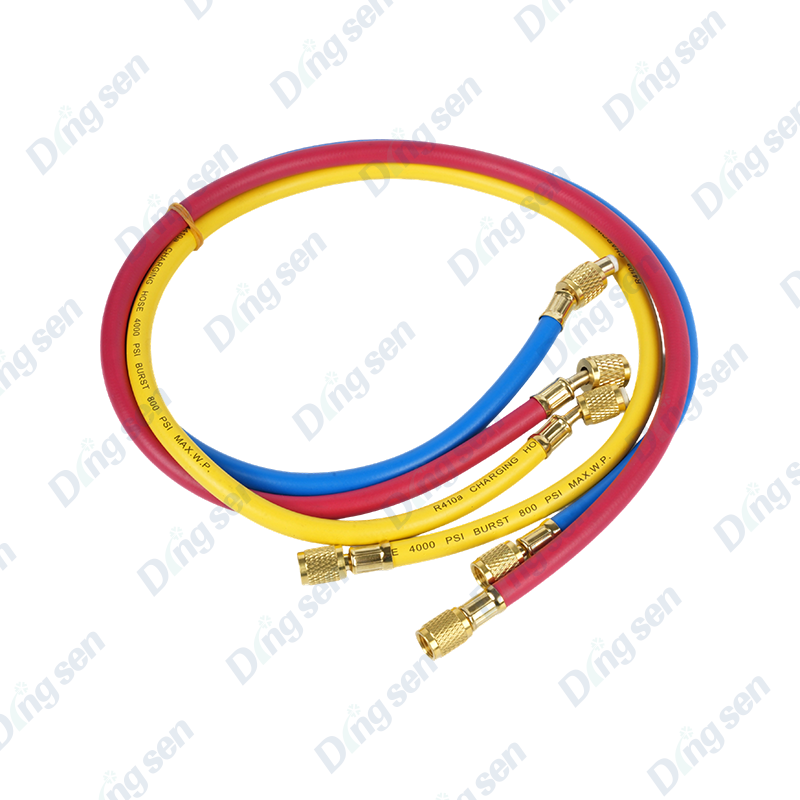

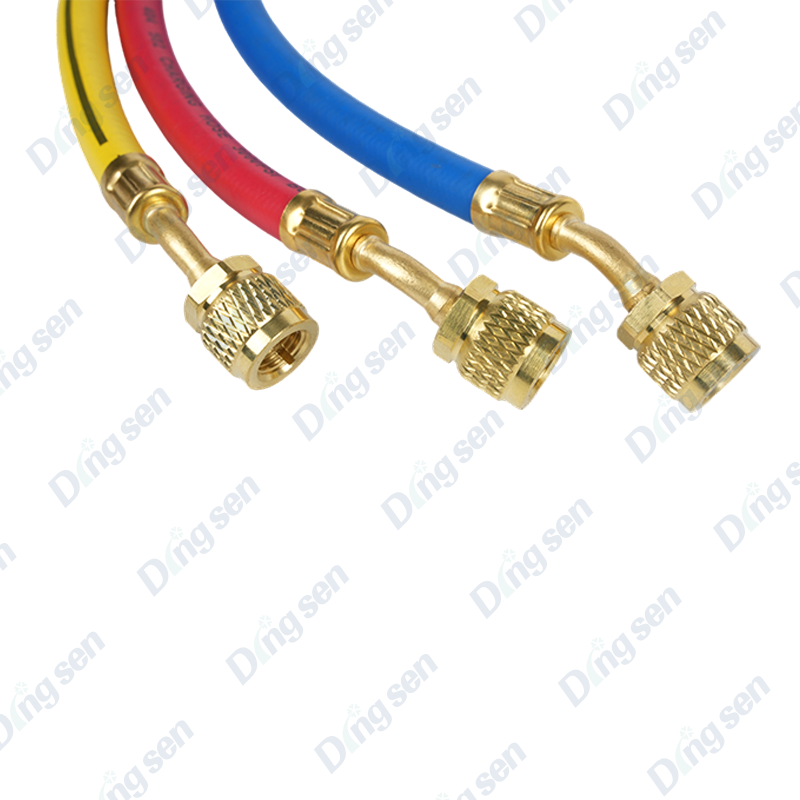

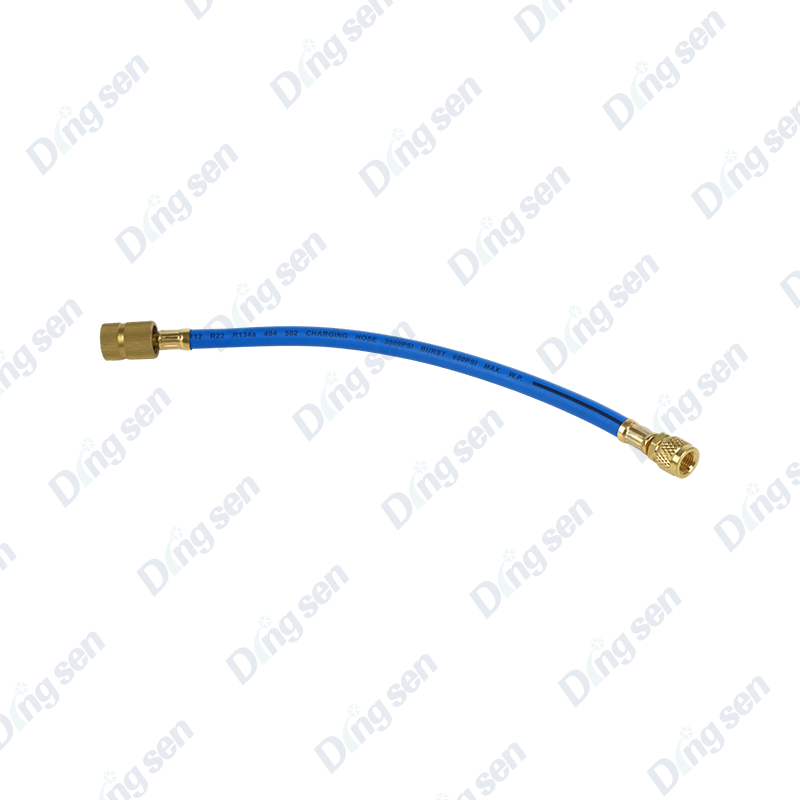

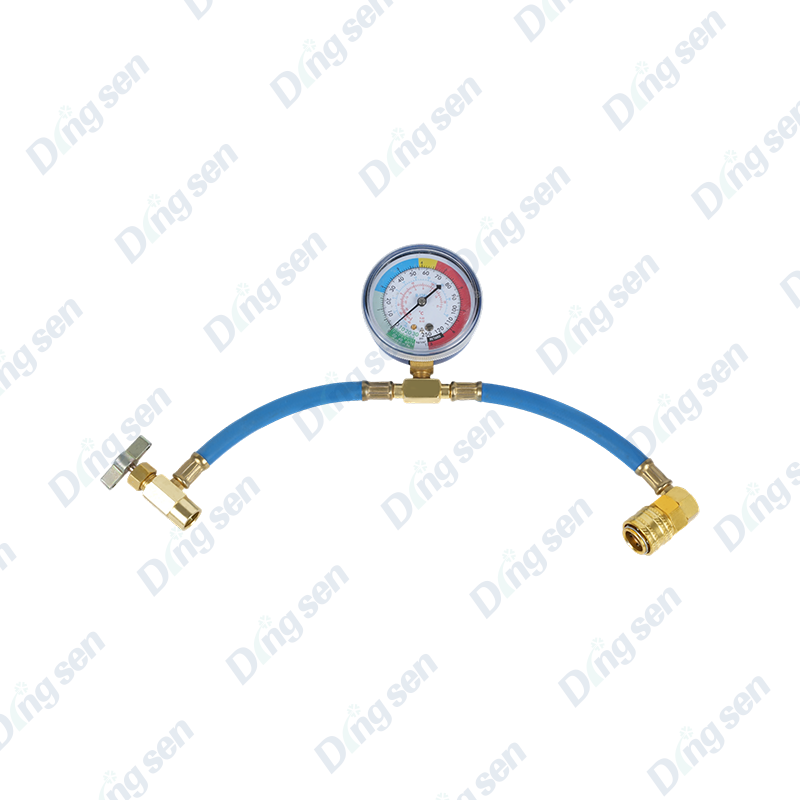

READ MOREFluorine filling hose

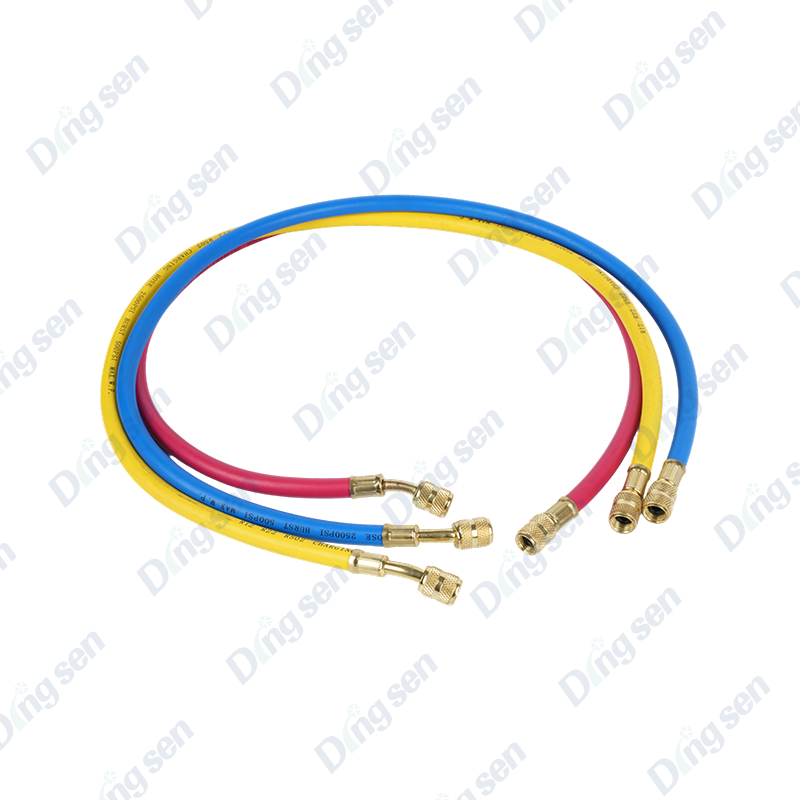

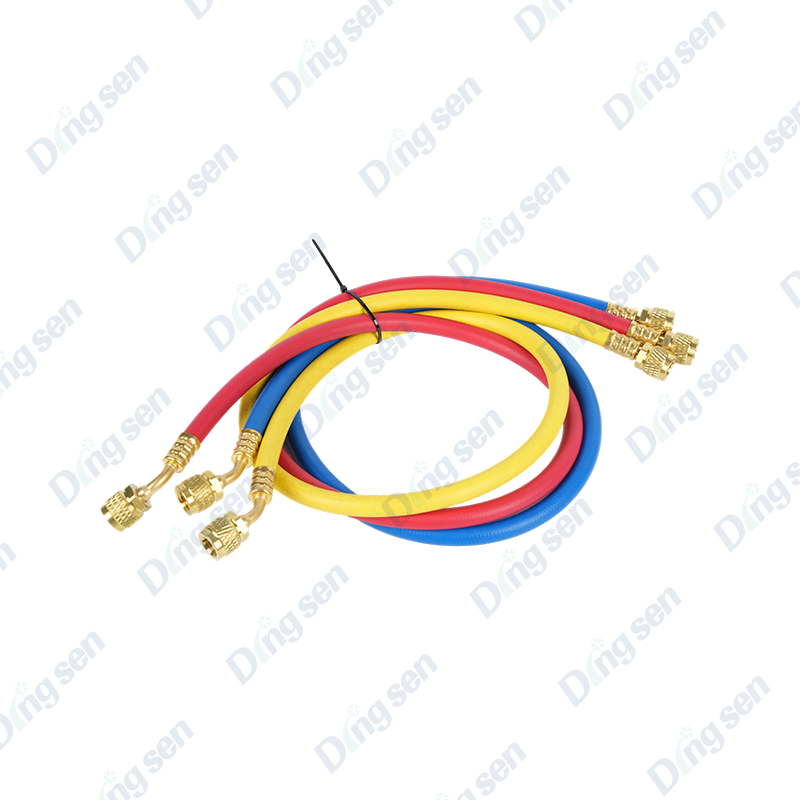

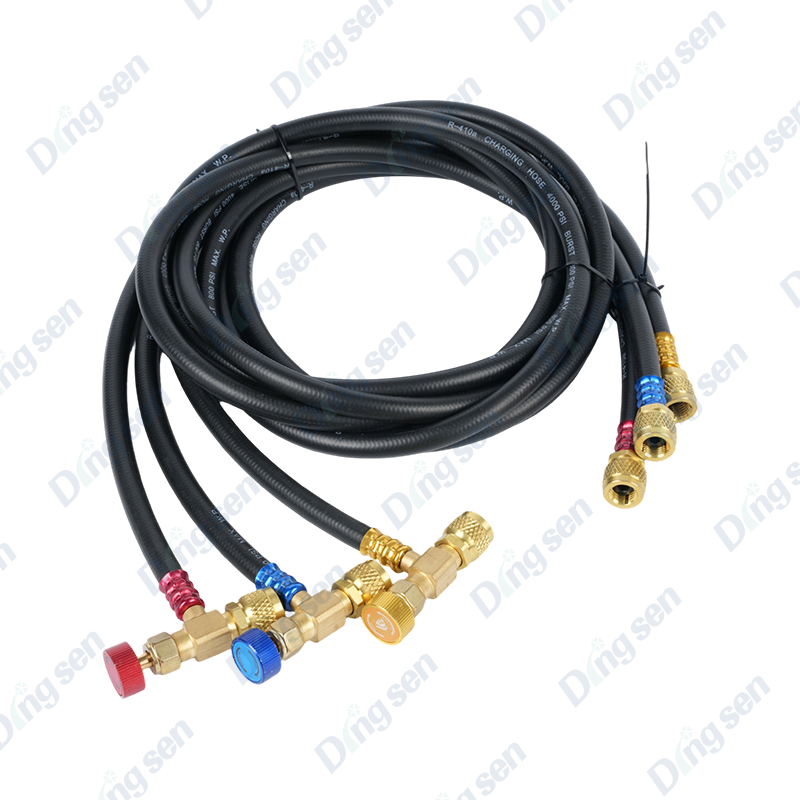

Fluorine filling hoses are specialized refrigerant transfer lines used to refrigerant air conditioners and other refrigeration equipment. They connect the fluorine filling equipment to the system interface, ensuring leak-free refrigerant transfer and efficient and safe filling operations.

Suitable for residential and commercial air conditioners and refrigeration units, they meet the media transfer needs during refrigerant filling and pressure testing.

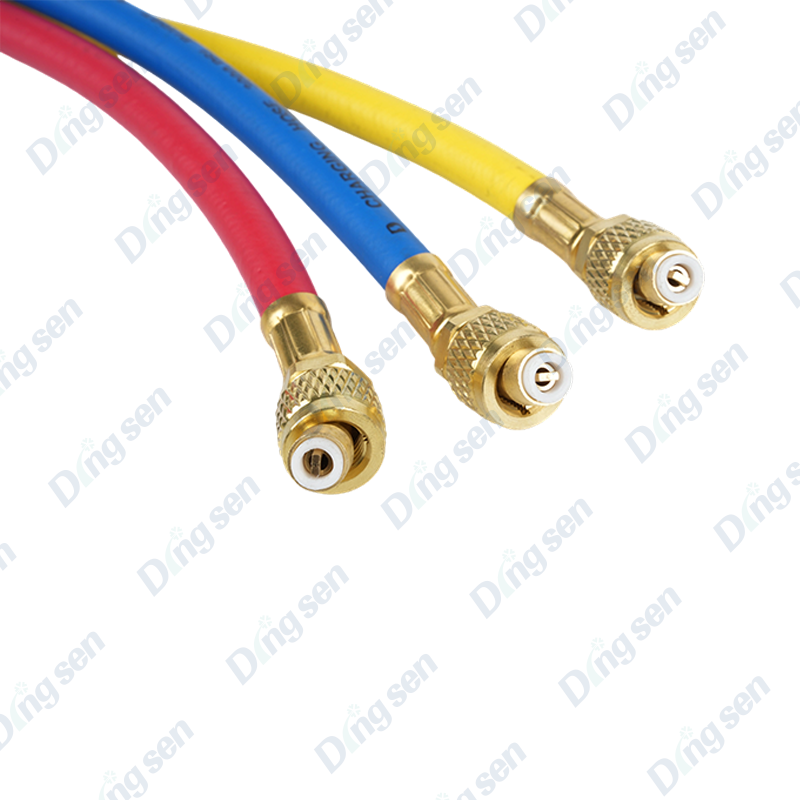

Manufactured with a refrigerant-resistant rubber inner layer and a wear-resistant outer layer, they undergo pressure and seal testing to ensure reliable performance.

Service includes pre-sales selection and after-sales maintenance guidance. Advantages include excellent sealing, corrosion resistance, excellent flexibility, and a wide range of compatibility.

Fluorinated hoses are dedicated transmission pipelines for refrigerant filling and pressure testing in refrigeration equipment. Their core advantage lies in "efficient sealing + strong environmental adaptability." They feature a three-layer composite structure. The inner layer is made of special refrigerant-resistant rubber (compatible with mainstream refrigerants such as R22, R410A, R32, and R134a), which can withstand a wide temperature range of -40°C to 120°C and refrigerant erosion for a long time, preventing medium penetration. The middle layer is a high-strength fiber braided reinforcement layer that can resist pipe expansion or rupture caused by pressure fluctuations during filling operations. The outer layer is made of wear-resistant and aging-resistant PVC material, which can prevent scratches and damage during dragging, thereby extending the service life. Both ends are equipped with standardized quick-connect connectors and built-in leak-proof valve cores. No additional seals are required when connecting to a fluorine meter, refrigerant bottle, or equipment interface, making insertion and removal easy. The pipe is highly flexible and suitable for operation in confined spaces (such as inside air conditioner outdoor units and ceiling-mounted units). Length specifications cover 1.5m to 5m to meet different working distance requirements. Some models are marked with pressure scale lines to facilitate intuitive judgment of the pipe pressure status. Application scenarios cover a wide range of refrigeration equipment including household wall-mounted/cabinet air conditioners, commercial central air conditioners, multi-split units, refrigeration units, automotive air conditioners, etc. Whether it is professional maintenance personnel on-site fluorine refilling, regular enterprise equipment maintenance, or factory commissioning by the manufacturer, it can ensure stable and leak-free refrigerant transmission. It also adapts to the media path requirements during pressure testing, providing safe and efficient transmission guarantee for refrigeration system maintenance.

-

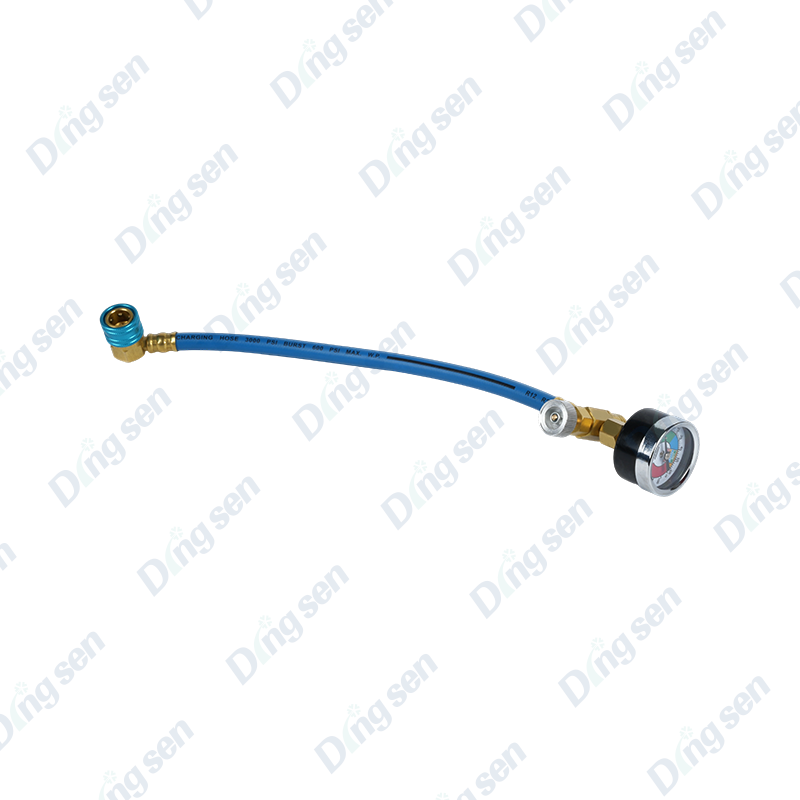

The Inflatable hose automotive air conditioning filling system is a flexible con...

-

Fluorination table adjustable conversion joint feature a compact overall design,...

-

The Safety filling valve series is a safety control component during media filli...

-

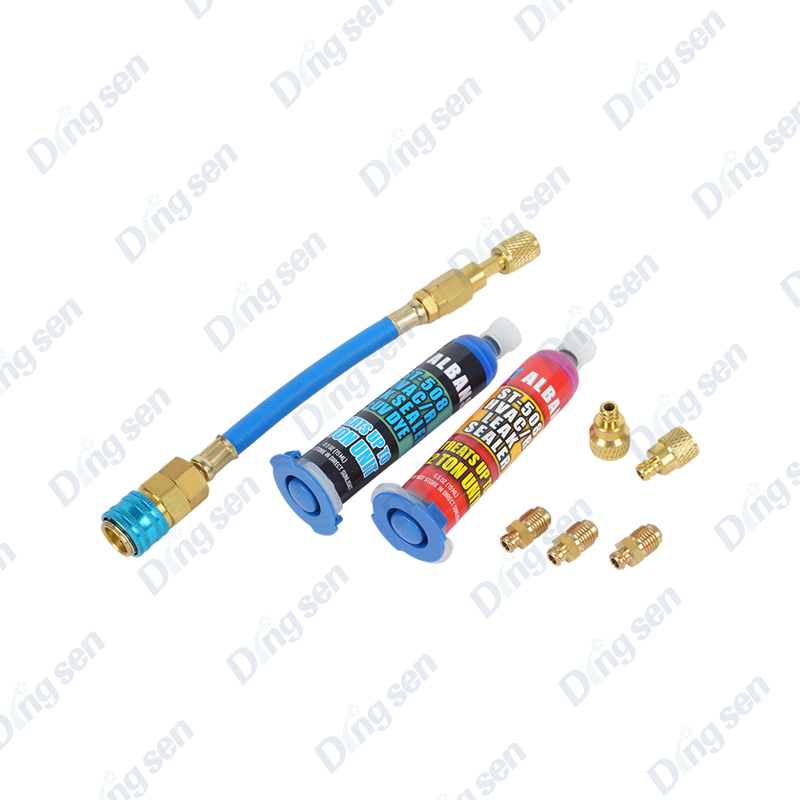

The air conditioning refrigerant filling tool is a professional repair accessory...

-

The automotive air conditioning sealant filling system is a one-stop repair tool...

-

Pressure gauge automotive air conditioning filling system are designed specifica...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى