In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

READ MOREFluorine meter adjustable adapter

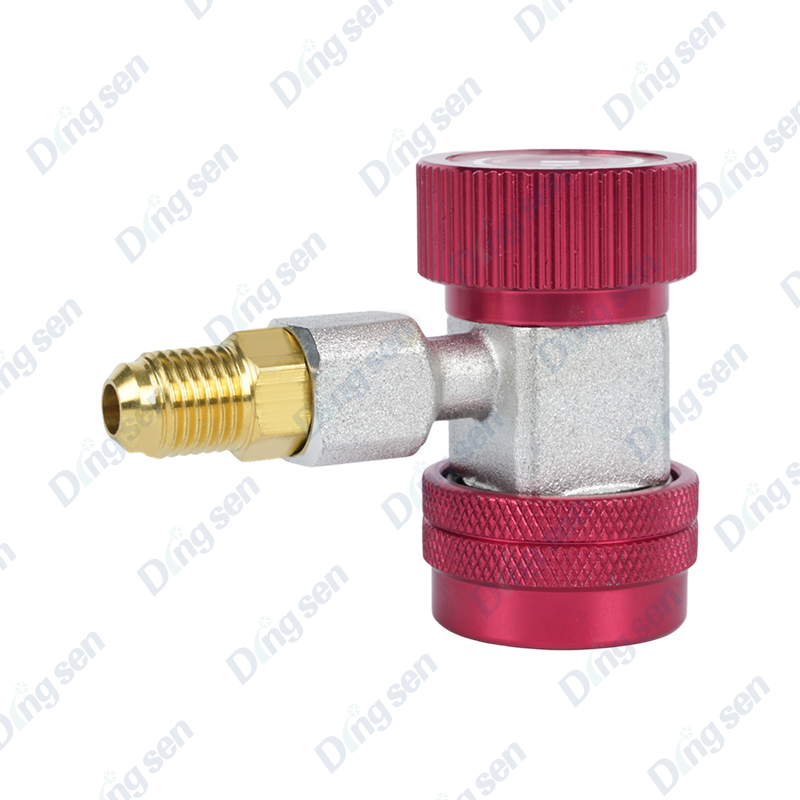

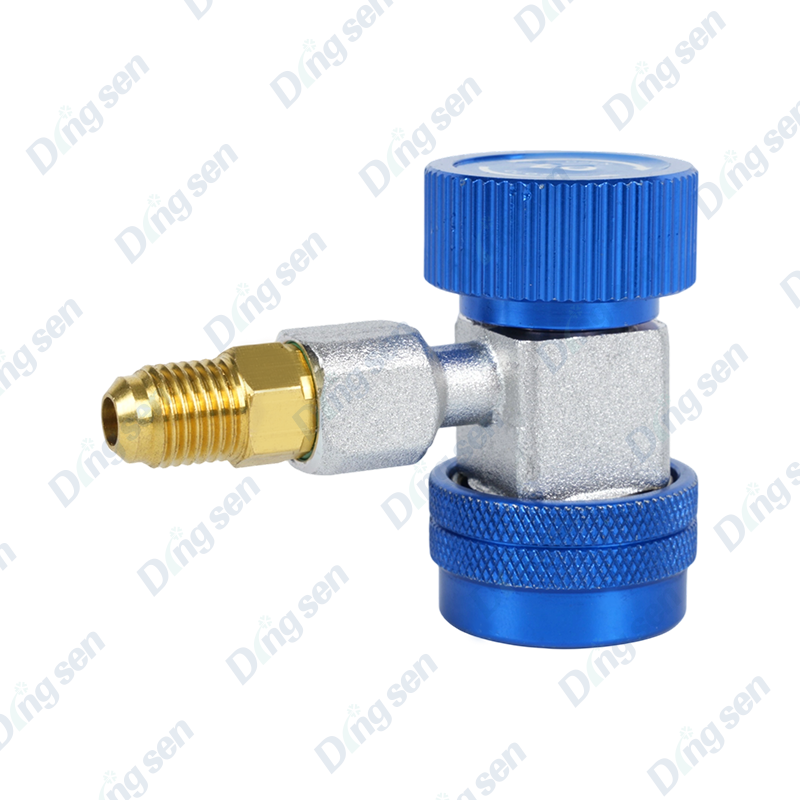

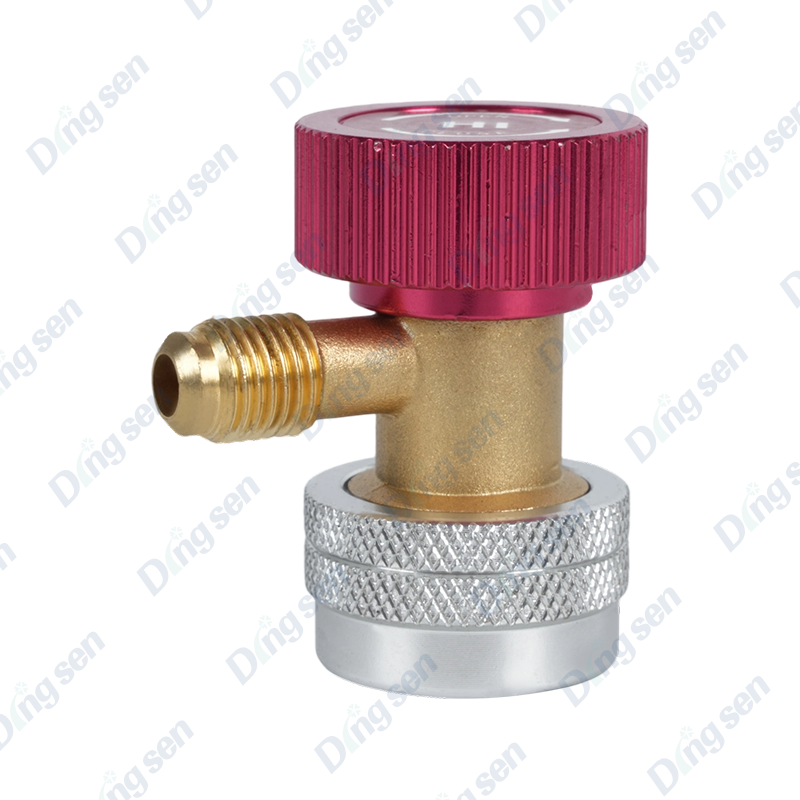

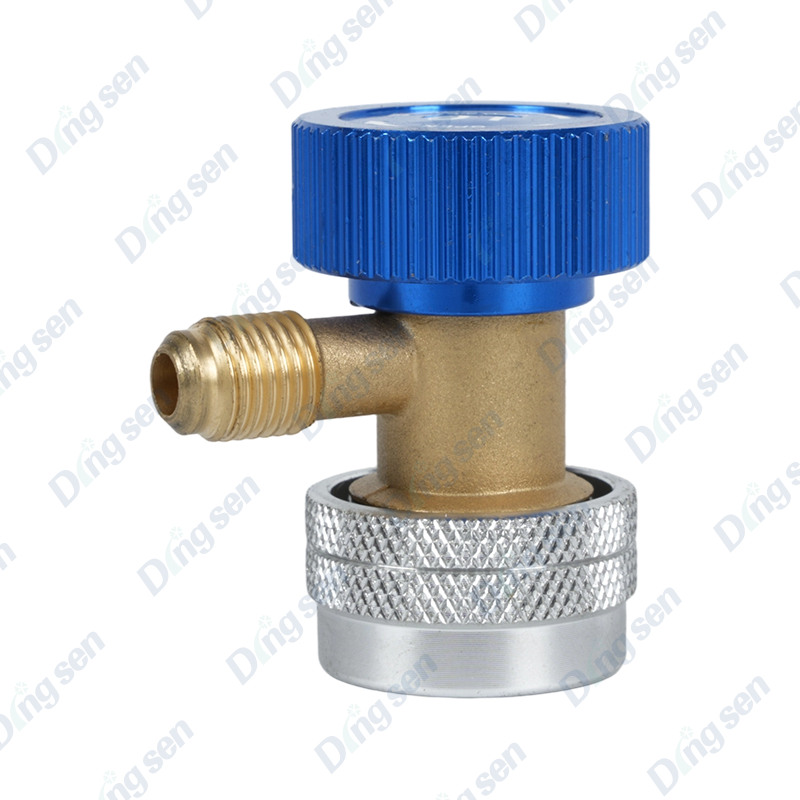

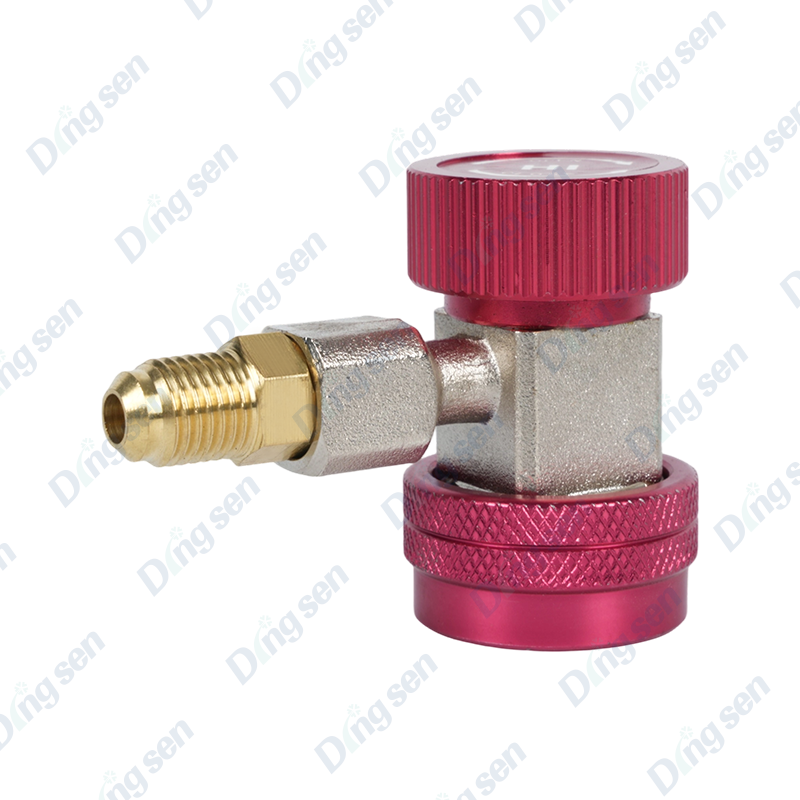

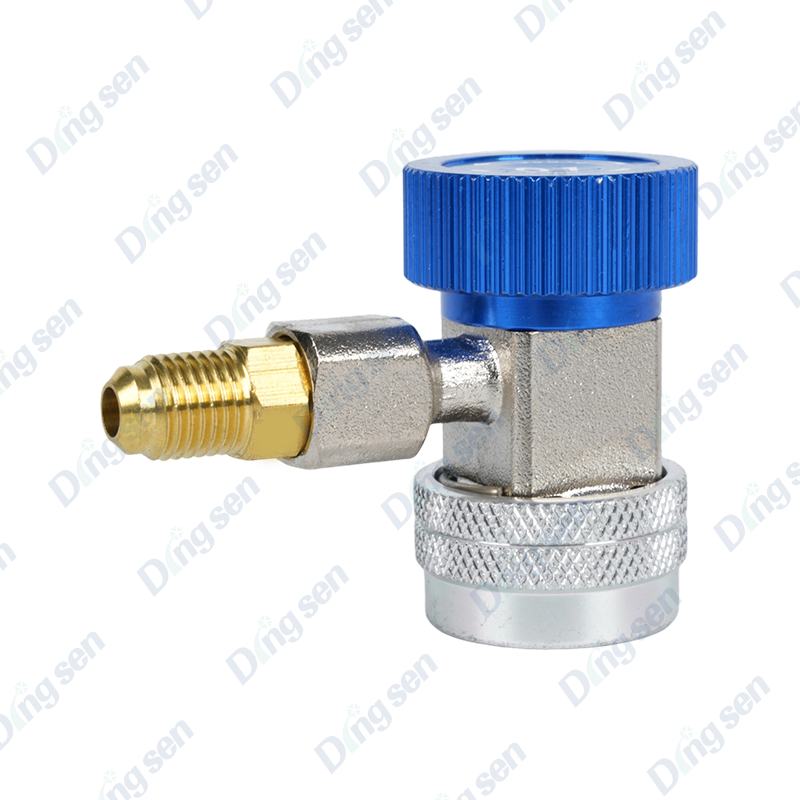

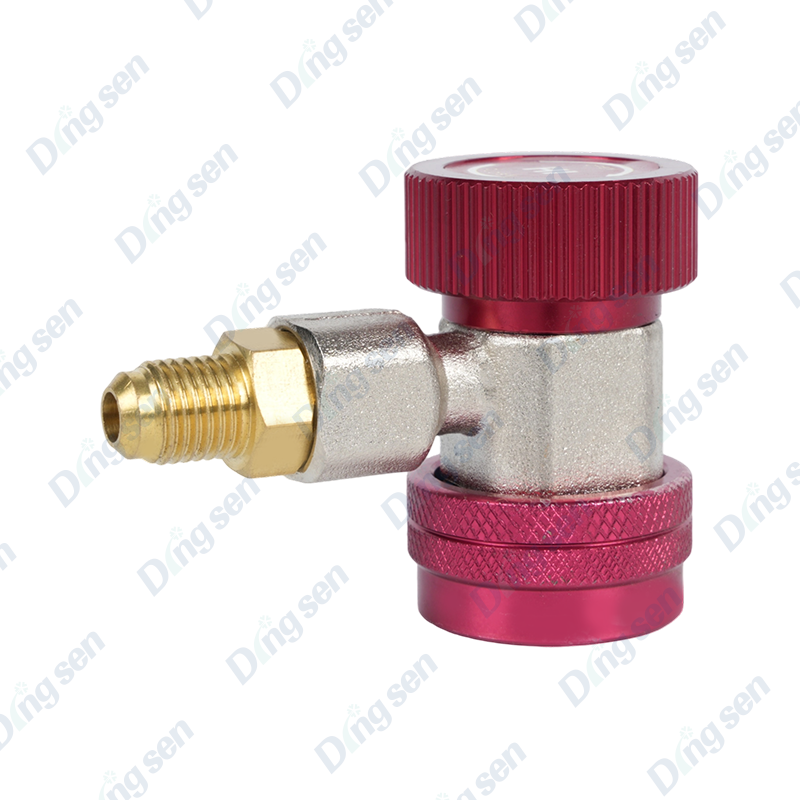

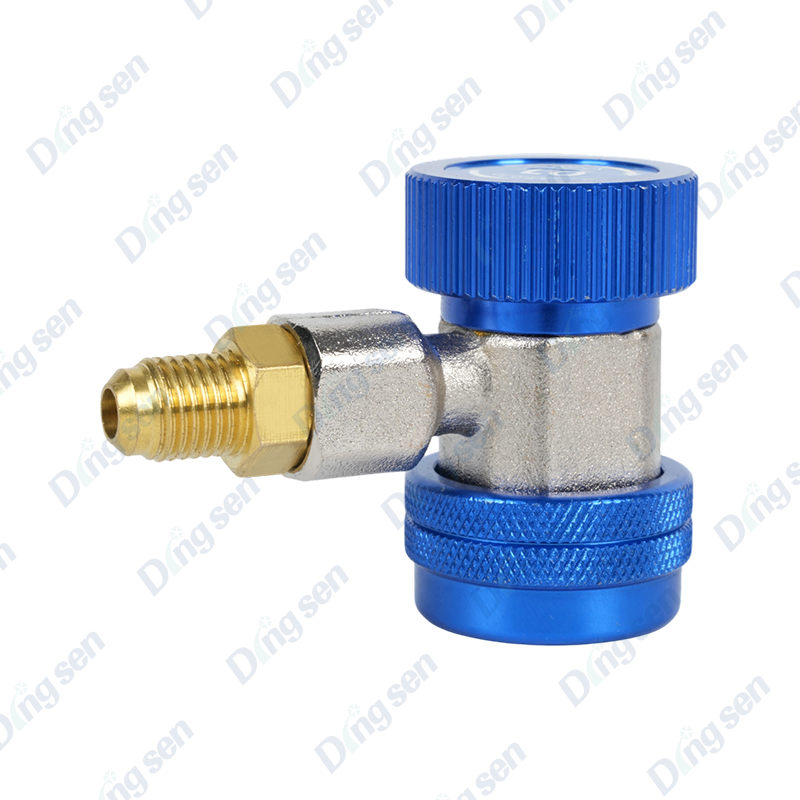

Fluorination table adjustable conversion joint feature a compact overall design, a 90 degree bend, and a main body typically equipped with an adjustable valve or bayonet. With advantages such as fast connection, excellent sealing, wide compatibility, and high durability, they have become an indispensable tool for automotive air conditioning repairs, providing strong support for efficient maintenance work.

1. Their compact overall design, typically equipped with an adjustable valve or bayonet, facilitates quick connection to air conditioning system piping and fluorination equipment.

2. Multiple sealing features, including double O-rings, ensure safe and accurate fluorination operations while preventing environmental pollution and increased costs caused by refrigerant leaks.

3. They adapt to various air conditioning piping connectors and operate stably under varying pressures and temperatures, meeting the maintenance needs of various refrigeration systems.

4. During the installation and repair of household and commercial air conditioners, such as mini-split and unitary air conditioners, they are used to connect refrigerant pipes to fluorination equipment, enabling refrigerant charging and system commissioning.

5. Working Principle

The quick-connect connectors, via bayonet or other quick-connect mechanisms, quickly connect to the high- and low-pressure ports of the air conditioning system. When connected to the air conditioning piping, internal sealing components (such as rubber seals and O-rings) create a seal, preventing refrigerant leakage during the refrigerant dosing process. After connecting to the dosing equipment, the refrigerant flow direction and volume can be controlled by adjusting the valve on the connector, enabling refrigerant filling and pressure testing.

-

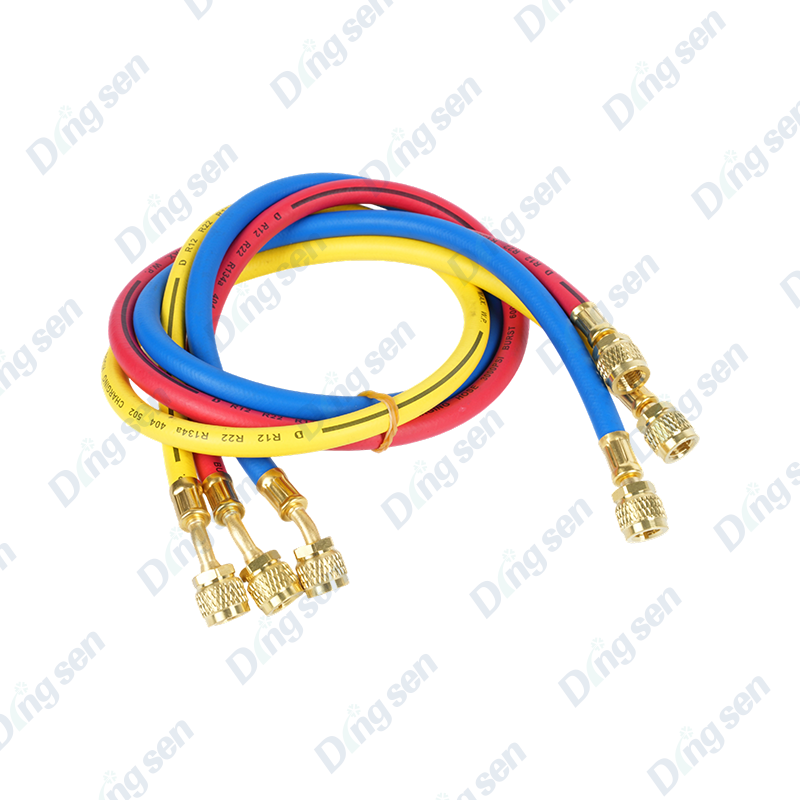

Fluorine filling hoses are specialized refrigerant transfer lines used to refrig...

-

The fluorination quick adapter is a specialized connector for automotive air con...

-

The fluorinated extended adapter is an accessory used to connect air conditionin...

-

The air conditioning refrigerant charging adapter is an adapter fitting for air ...

-

The car air conditioning fluorine charging guage is a dedicated instrument for r...

-

The all-copper fluorinated quick connector is a specialized connector for automo...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى