The Air Conditioning Copper Pipe Connector, with its efficient and reliable connection performance, is gradually replacing traditional welding and crimping methods, becoming the ideal connection solution for modern air conditioning systems. Compared to traditional methods, the Air Conditioning Coppe...

READ MORERefrigerant leak detector

The refrigerant leak detector is a specialized device for detecting leaks in refrigeration systems. It uses sensors to capture leaking refrigerant and quickly locate the source, preventing refrigerant waste and environmental damage while ensuring system cooling efficiency. It is suitable for a variety of cooling scenarios.

It is used for installation, acceptance, and maintenance inspection of air conditioners, refrigerators, cold storage, and automotive air conditioners.

It utilizes highly sensitive sensors and anti-interference circuitry, undergoes precision calibration, and undergoes durability testing to ensure accurate detection and robust stability.

The service includes model selection and operation guidance. Advantages include fast leak detection, high accuracy, interference resistance, portability, and ease of operation. Refrigerant leak detectors are core equipment for leak testing in refrigeration systems. Their core advantages are "high-precision detection + efficient positioning." Equipped with imported semiconductor or infrared sensors, they can accurately identify mainstream refrigerants such as R22, R410A, and R32. Built-in intelligent anti-interference algorithms effectively filter out oil and water vapor interference, resulting in detection accuracy exceeding 99%. Some models feature a numerical display for real-time leak concentration. Automatic calibration eliminates the need for frequent factory adjustments. Battery life reaches 8-12 hours, enabling extended outdoor operation. The probe is removable and washable, extending sensor life. Applications include installation and acceptance testing (testing the tightness of new unit piping), routine maintenance (regular leak detection to prevent refrigerant loss), and troubleshooting (precisely locating leaks to minimize equipment disassembly) for residential and commercial air conditioners, refrigerators and freezers, cold storage refrigeration units, automotive air conditioners, and industrial refrigeration equipment. Whether performed by professional maintenance personnel on-site or during factory production line quality inspection, these devices can quickly identify potential refrigerant leaks, preventing refrigerant waste and environmental pollution while ensuring efficient and stable operation of the refrigeration system.

-

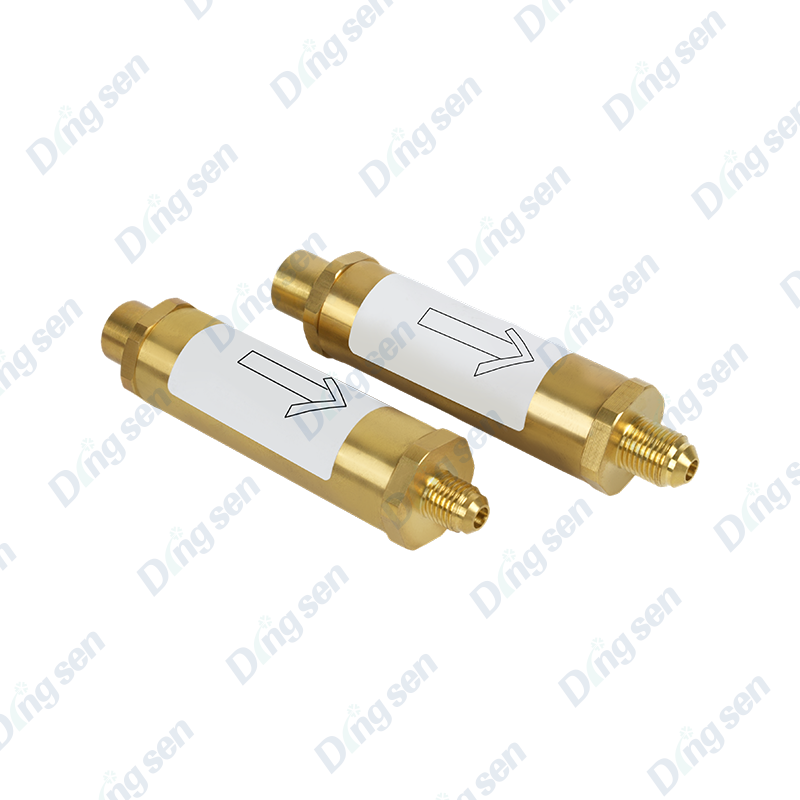

The refrigerant gas-liquid separator is a core separation component in refrigera...

-

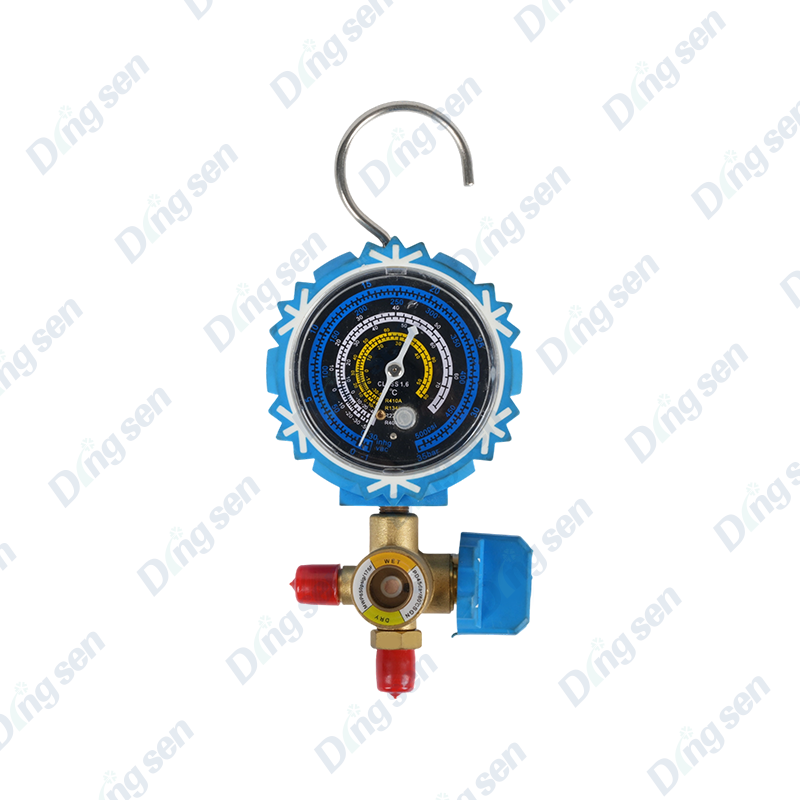

The refrigerant single gauge is a specialized instrument for refrigerant system ...

-

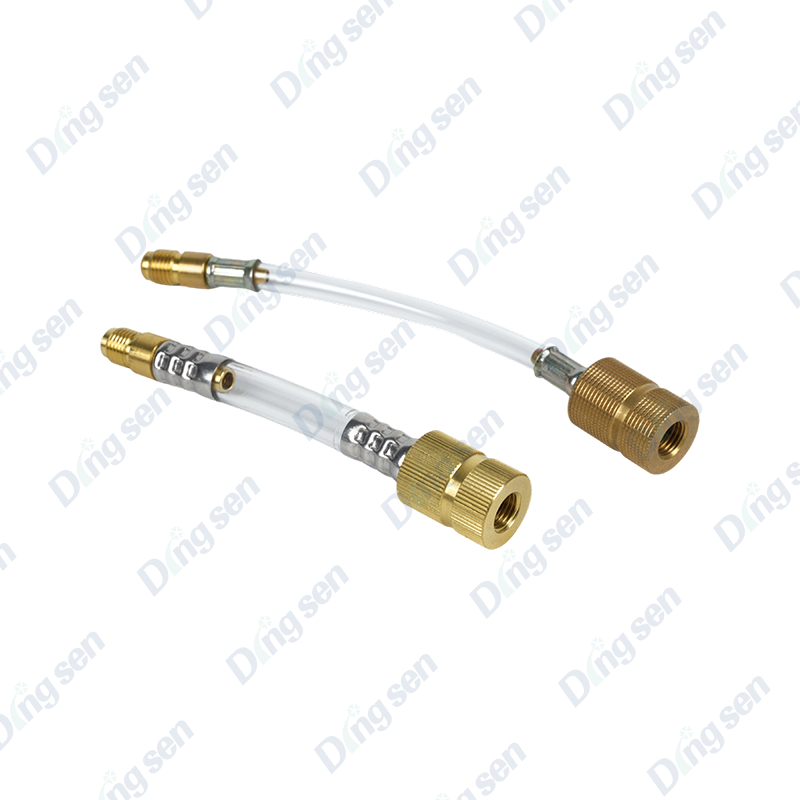

Refrigerant and refrigeration oil filler is a special device for replenishing me...

-

The Refrigerant rapid injection pump automotive air conditioning filling system ...

-

Refrigerant vaporizer are key components in refrigeration systems, rapidly atomi...

-

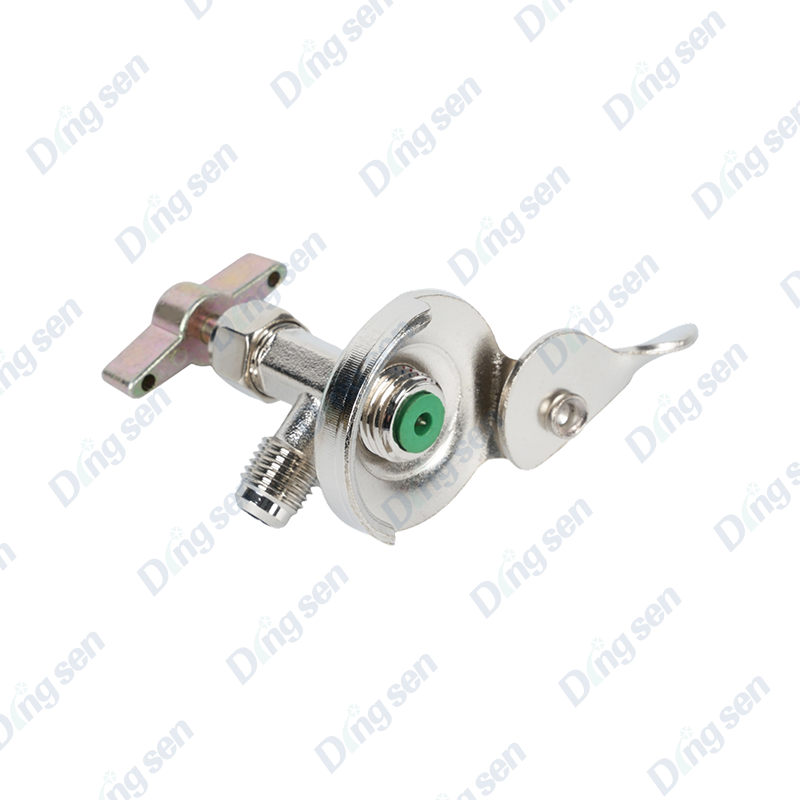

Universal faucet refrigerant bottle opener industrial valve is designed specific...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

The main differences between Quick Connector for Car Air Conditioning and traditional fittings lie in installation convenience, sealing reliability, and maintenance efficiency. Traditional fittings usually require threaded or flange connections, which have long installation cycles and are prone to l...

READ MORE -

Refrigeration and air conditioning system accessories effectively enhance the operational safety and stability of the entire system through multiple mechanisms, including structural protection, pressure control, electrical protection, and intelligent monitoring. From pipeline fittings and valve comp...

READ MORE

en

en  Español

Español عربى

عربى