In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

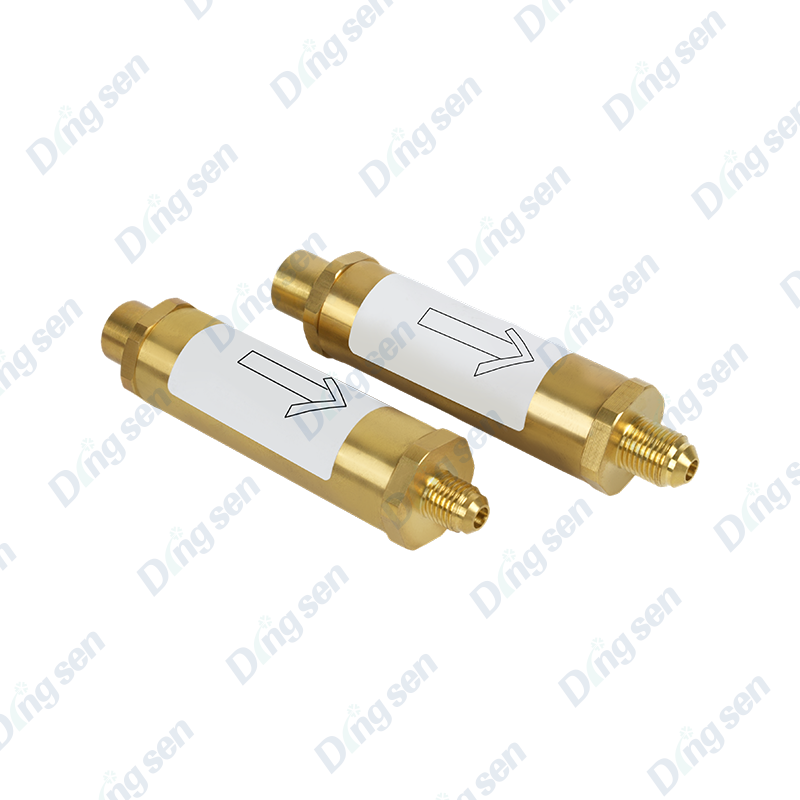

READ MORERefrigerant gas-liquid separator

The refrigerant gas-liquid separator is a core separation component in refrigeration systems. It efficiently separates the gas and liquid phases in the refrigerant, preventing liquid refrigerant from entering the compressor and causing liquid hammer, thereby ensuring safe and efficient operation of the unit.

It is suitable for return air lines in refrigeration equipment, air conditioning systems, and various refrigeration units, meeting separation requirements in various scenarios.

It utilizes a heat-resistant and pressure-resistant housing, undergoes precision molding, and undergoes air-tightness testing to ensure stable separation performance.

Our service includes pre-sales selection and after-sales maintenance guidance. Advantages include excellent separation efficiency, a wide range of compatibility, strong durability, and easy installation.

As a key gas-liquid separation device in the refrigeration system, the refrigerant gas-liquid separator has significant core advantages: it adopts a high-efficiency separation structure design, and through the dual effects of inertial separation and centrifugal separation, it can accurately separate the gas and liquid phases in the refrigerant return line, with a separation efficiency of over 98%. It can effectively prevent liquid refrigerant from entering the compressor and causing liquid hammer failure, avoiding problems such as cylinder damage and motor burning caused by liquid hammer in the compressor. At the same time, it reduces the oil shortage and wear of the compressor caused by the discharge of lubricating oil with the liquid refrigerant, significantly improving the operating safety and stability of the unit and extending the service life of the compressor. The shell is made of high-quality, heat-resistant and pressure-resistant alloy material, and is processed through precision casting and integral molding technology. It can withstand a wide temperature range of -50℃~150℃ and high-pressure environment, and the built-in anti-liquid hammer buffer structure can further enhance the stability of system operation. Core selling points directly address industry pain points: stable separation efficiency, eliminating the need for frequent maintenance and adjustments; compatibility with mainstream refrigerants such as R22, R410A, and R32, and compatible with units of varying cooling capacities, eliminating the need for customization based on refrigerant type or unit specifications, reducing procurement and inventory costs; and flexible installation options, supporting horizontal or vertical installation to accommodate diverse piping layouts. Suitable for a wide range of applications, the product can be installed in residential central air conditioners, commercial refrigerated display cabinets, supermarket cold chain systems, industrial cold storage, and the return air lines of large chillers. It provides reliable gas-liquid separation for various refrigeration systems, ensuring continuous and efficient operation of units, reducing the frequency of repairs, and lowering long-term maintenance costs.

-

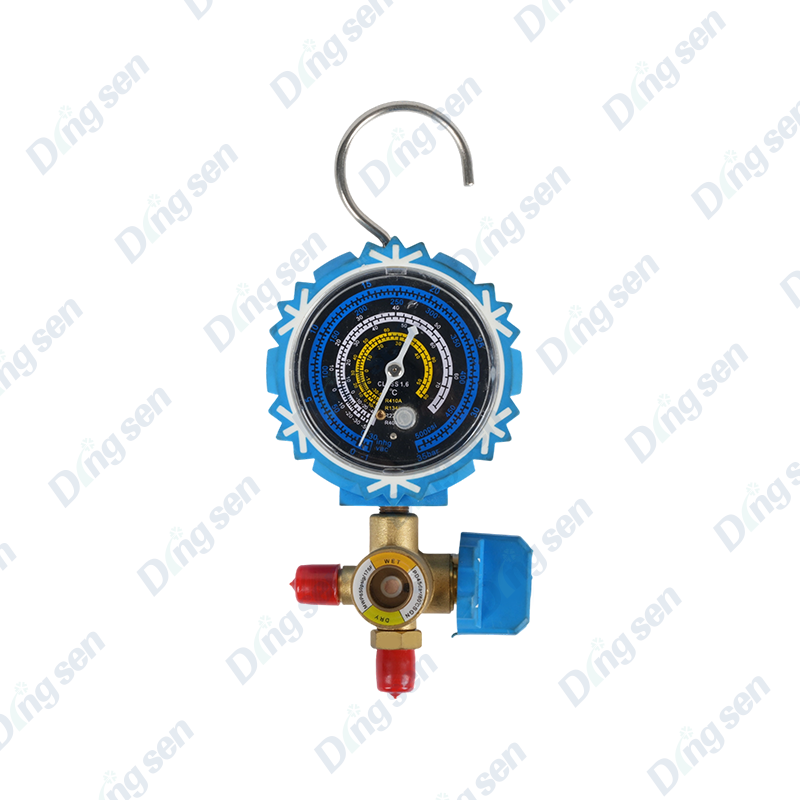

The refrigerant single gauge is a specialized instrument for refrigerant system ...

-

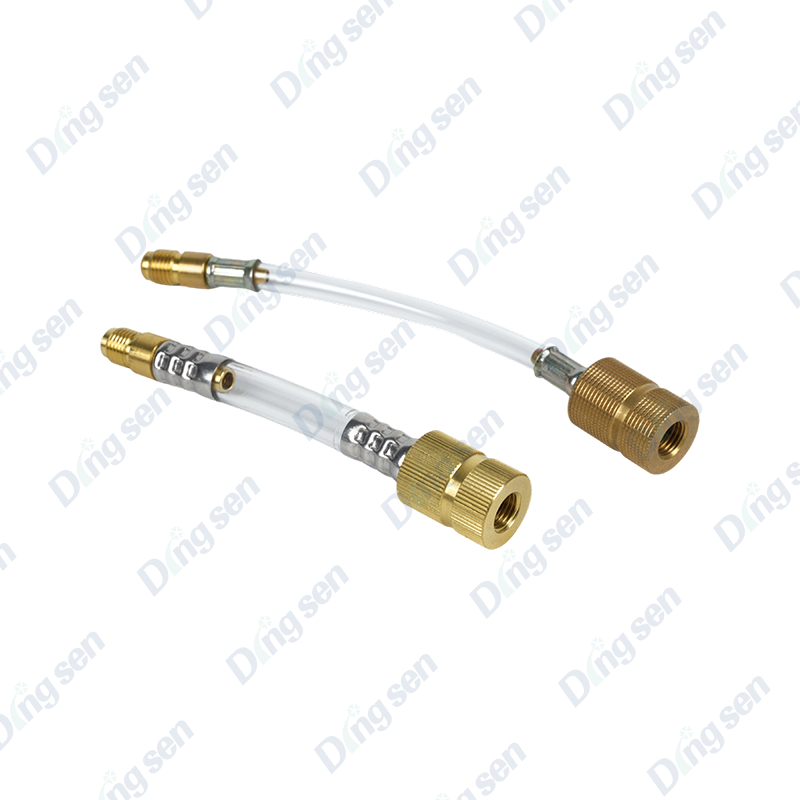

Refrigerant and refrigeration oil filler is a special device for replenishing me...

-

The refrigerant leak detector is a specialized device for detecting leaks in ref...

-

The Refrigerant rapid injection pump automotive air conditioning filling system ...

-

Refrigerant vaporizer are key components in refrigeration systems, rapidly atomi...

-

The brass refrigerant distribution liquid separator is a core component of refri...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى