In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

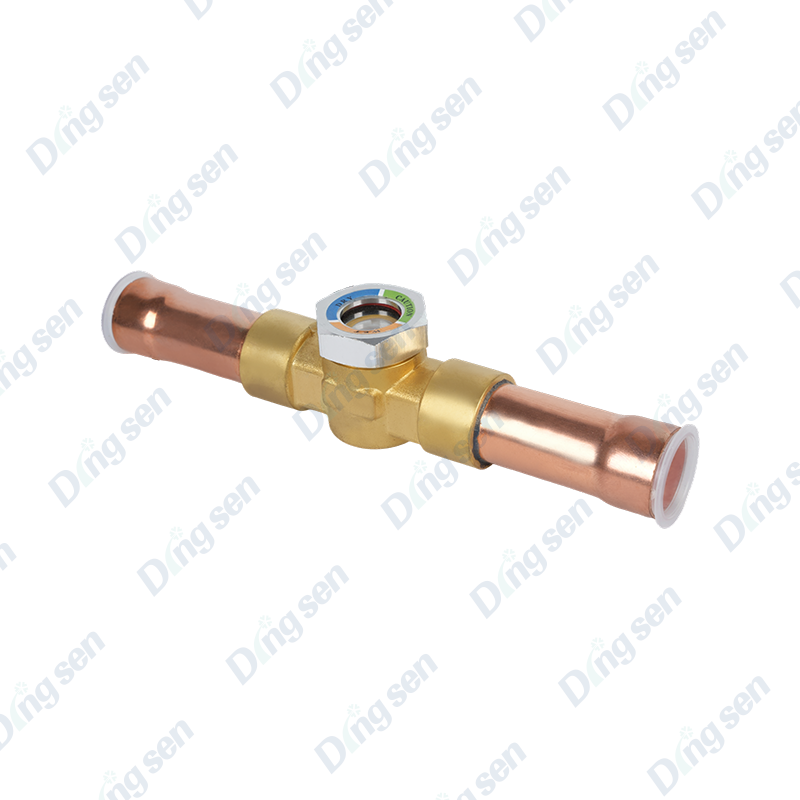

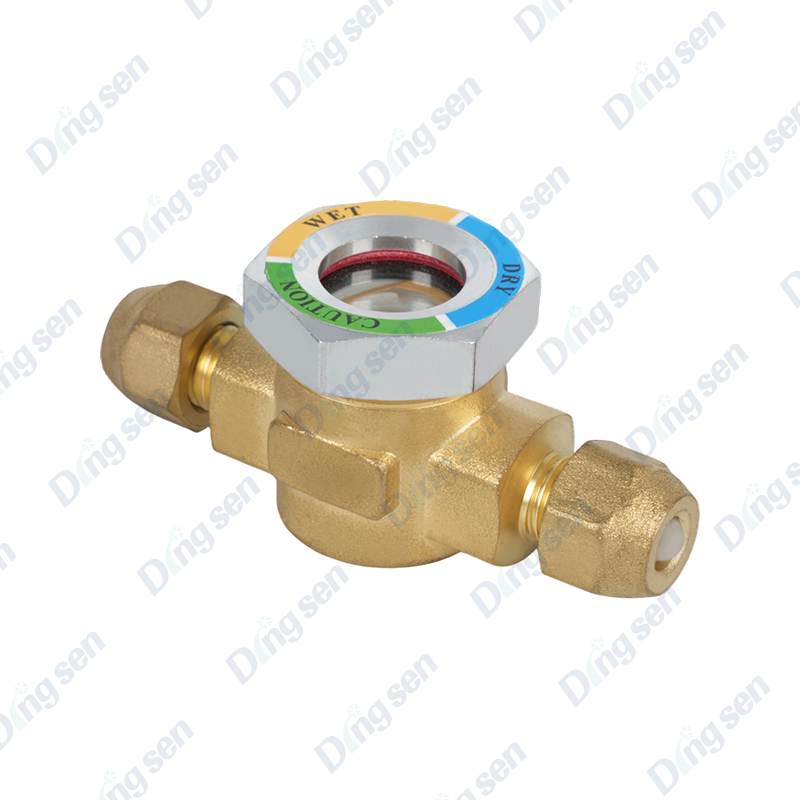

READ MORECartridge-type sight glass

The cartridge-type sight glass is a visual monitoring component for refrigeration systems. It features a snap-on installation and uses a high-resolution lens to provide real-time visualization of the media's status, assisting in determining system operation.

It is suitable for liquid pipelines in refrigeration, air conditioning, and refrigeration units. It is manufactured using corrosion-resistant, highly transparent materials and undergoes sealing and pressure resistance testing for strict quality control.

Pre-sales selection and after-sales maintenance guidance are provided. Advantages include fast installation, clear visualization, wide compatibility, and strong durability.

The cartridge-type sight glass is a key visual monitoring component for refrigeration systems. Its key advantages include a snap-on installation design that requires no complex tools and can be assembled by one person in minutes, significantly reducing installation time and labor costs. This differs from the tedious process of traditional welded sight glasses, which require specialized expertise. The lens is made of highly transparent, corrosion-resistant material with high light transmittance and resistance to refrigerant and refrigeration oil corrosion. It remains clear and fog-free even after long-term use. It provides real-time, accurate visualization of the media's status within the pipeline, such as the presence of bubbles, oil film, or impurities. This helps quickly determine operational issues such as system fluid shortages and proper oil return, preventing equipment failures caused by untimely monitoring. The snap-fit mechanism adapts to liquid pipelines of various diameters, eliminating the need to select individual pipes by diameter and reducing inventory pressure. It also offers excellent sealing properties and, when paired with heat-resistant seals, prevents leakage even in wide operating temperatures, ensuring both safety and practicality. It has a wide range of applications, including household air conditioners, commercial refrigerated display cabinets, industrial cold storage, and liquid pipelines in large refrigeration units. It provides reliable support for the efficient operation and maintenance of refrigeration equipment of all sizes, helping users promptly identify and resolve system risks and ensure long-term stable operation.

-

-

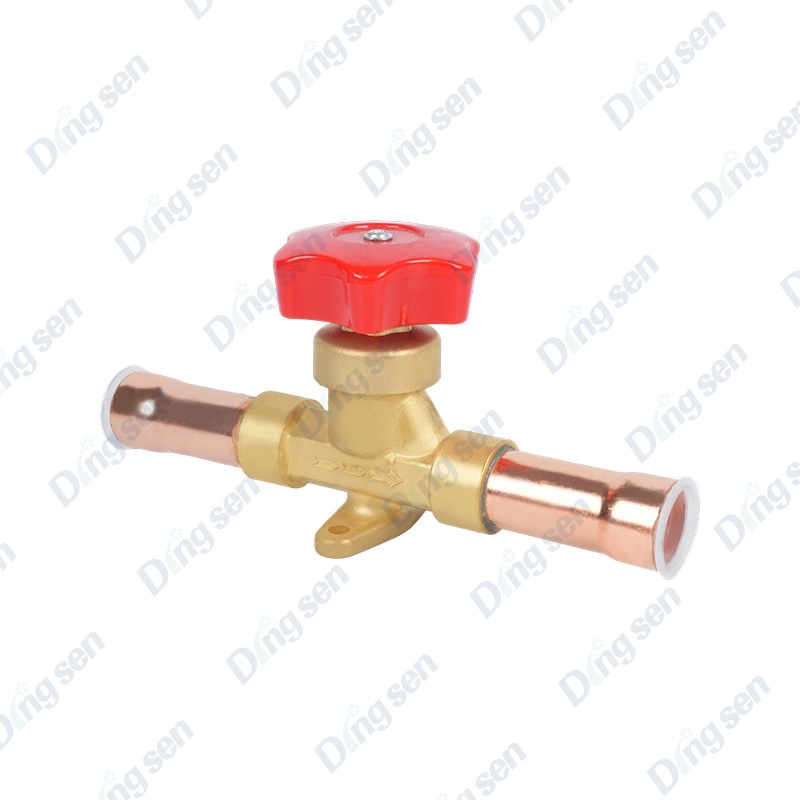

Diaphragm-type hand valves are manual flow control components for refrigeration ...

-

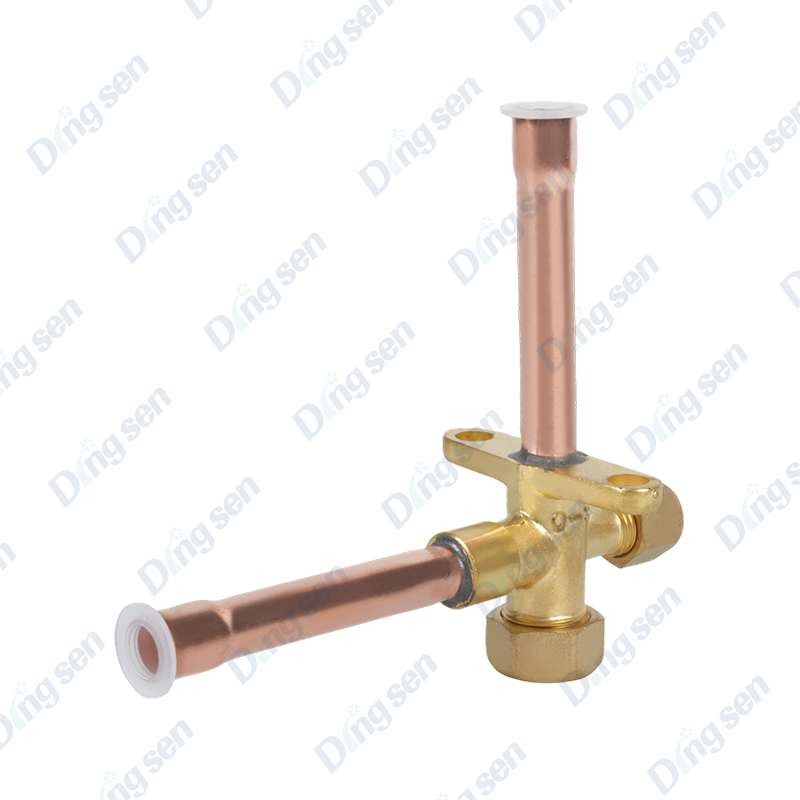

The air conditioning three-way valve is a key component for switching and contro...

-

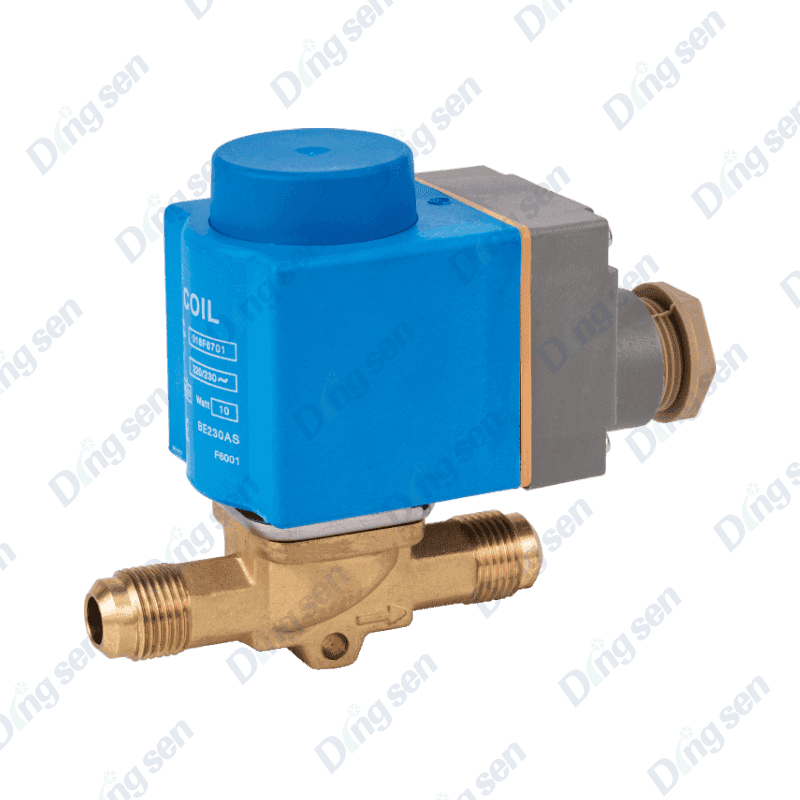

The EVR type solenoid valve features a split upper and lower structure, with a b...

-

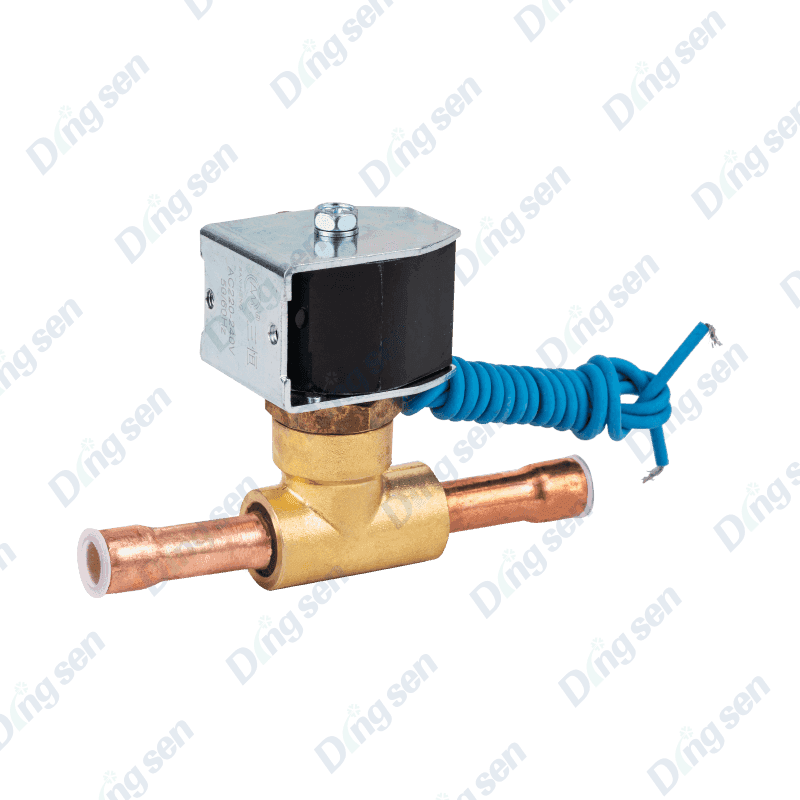

The FDF type solenoid valve is a highly reliable valve designed specifically for...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى