In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

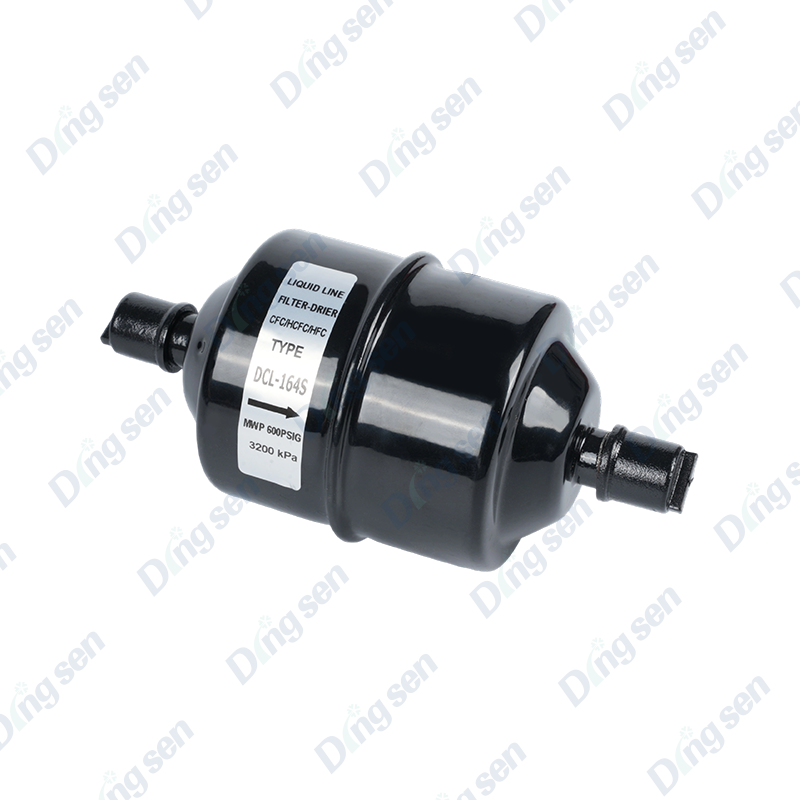

READ MOREDFS filter

DFS filters are core components for media purification in refrigeration systems. Their high-efficiency filter elements intercept impurities and absorb moisture, protecting critical components like the compressor from wear and tear.

They are suitable for liquid and air intake lines in refrigeration, air conditioning, and refrigeration units.

They are manufactured with corrosion-resistant housings and high-contamination filter elements, tested for pressure resistance and filtration efficiency.

Pre-sales selection and after-sales filter element replacement guidance are provided. Advantages include precise filtration, corrosion resistance, wide compatibility, and easy maintenance.

The DFS filter is a key component for media purification in refrigeration systems. Its core advantages are significant: It utilizes a composite high-efficiency filter element that combines both impurity interception and moisture adsorption. It precisely captures solid impurities such as metal debris and welding slag in the refrigerant, while efficiently adsorbing residual moisture in the pipeline to prevent acidic corrosion caused by the reaction of moisture and refrigerant. Its high filtration accuracy and strong dirt-holding capacity make it non-clogging even after long-term use. It effectively protects core components such as the compressor and solenoid valve from wear and damage, extending the overall service life of the equipment. The housing is constructed of corrosion-resistant materials that withstand long-term attack from refrigerants and refrigeration oil, adapting to complex high and low temperature operating conditions. Its specially designed sealing structure prevents secondary contamination of the filtered media. The filter element is easily replaceable without disassembling the entire valve, reducing maintenance time and costs. Compatible with mainstream refrigerants such as R22, R410A, and R32, it eliminates the need to select a specific filter type based on the refrigerant, reducing inventory pressure. It accommodates a variety of piping connections, allowing for flexible installation without space constraints. It has a wide range of application scenarios, from the liquid pipelines of household central air conditioners and commercial refrigerated display cabinets to the suction pipelines of industrial cold storage and large refrigeration units. It can stably play a purification role, ensuring the efficient and safe operation of refrigeration systems of different sizes, helping users reduce the frequency of equipment failures and reduce long-term operation and maintenance costs.

-

-

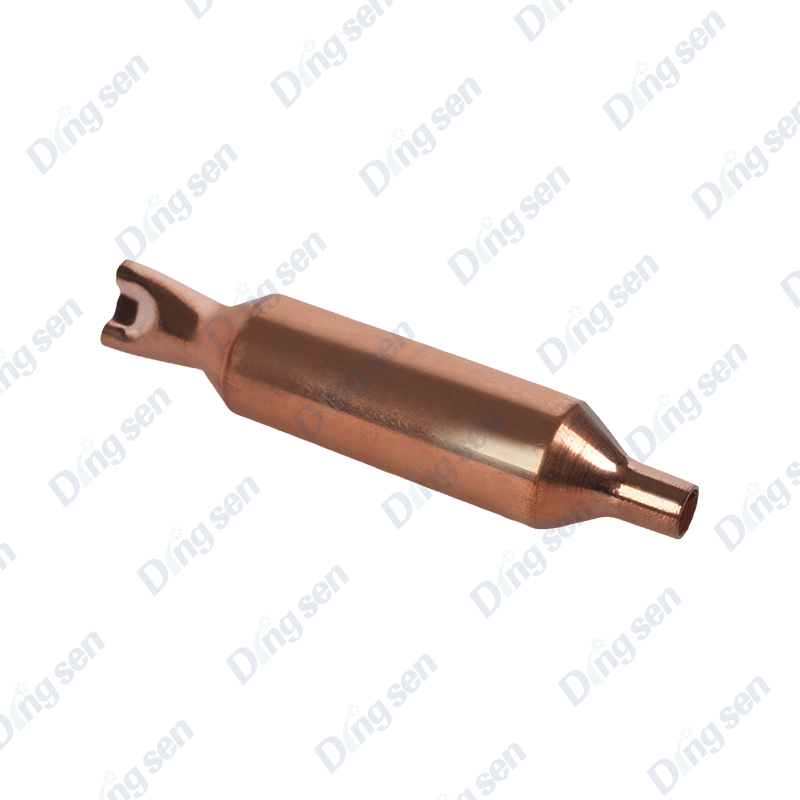

Refrigeration drying filter cylinder are drying and purification components in r...

-

The copper drying filter is a specialized purification component for refrigerati...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى