In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

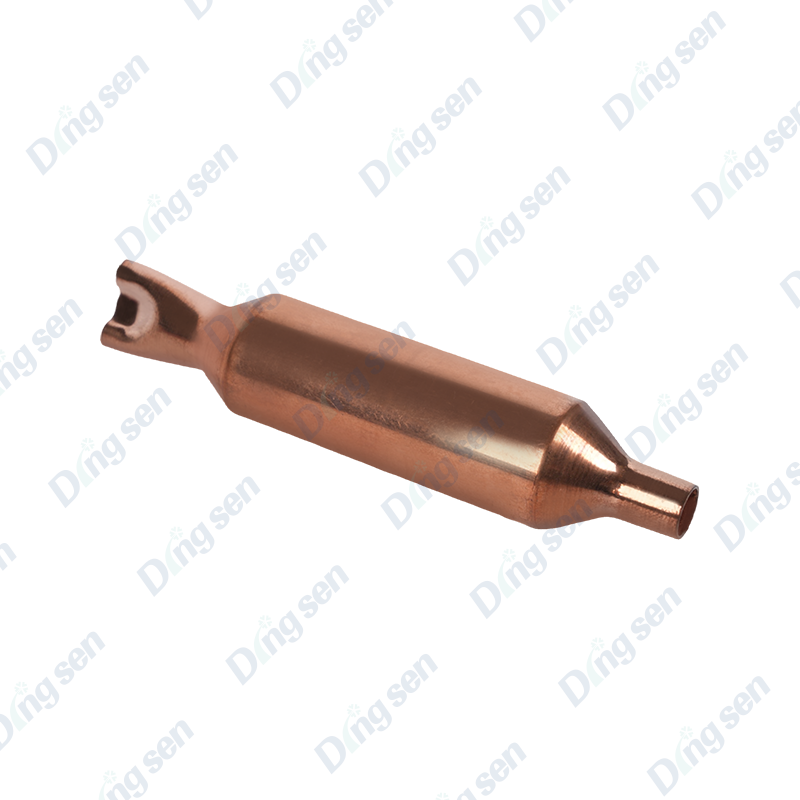

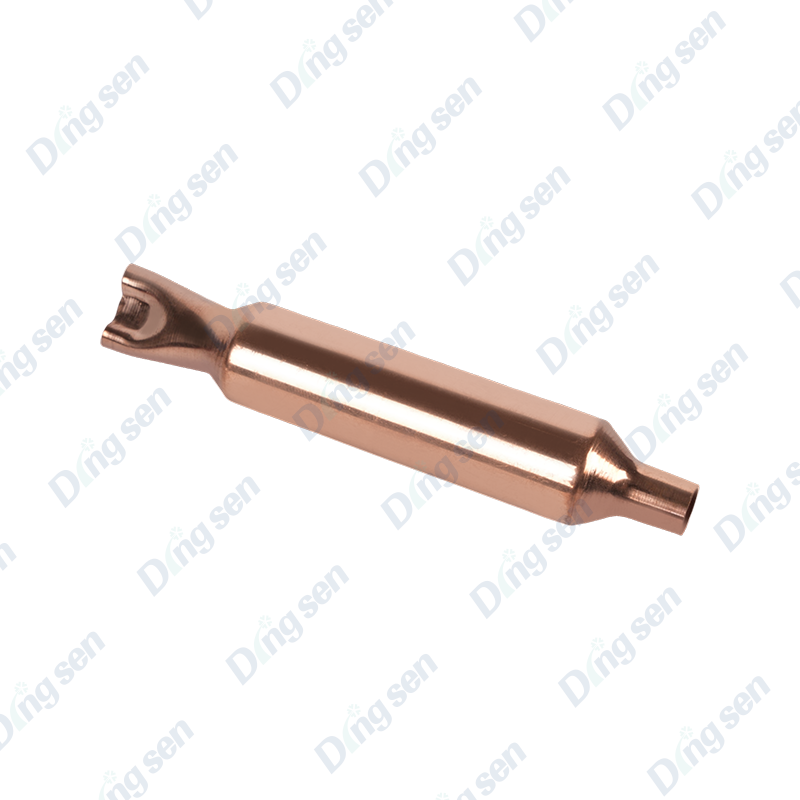

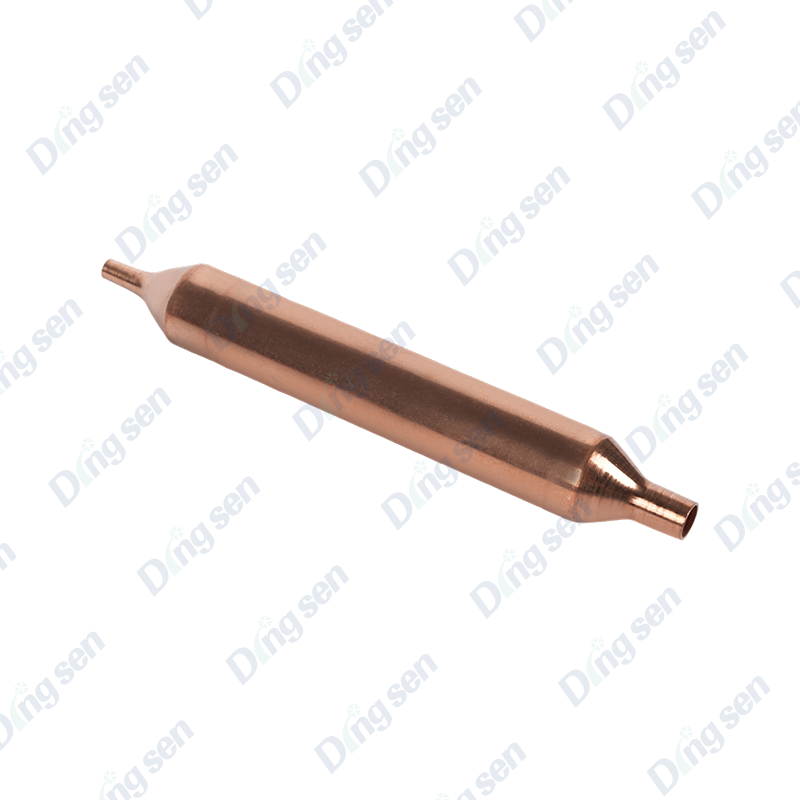

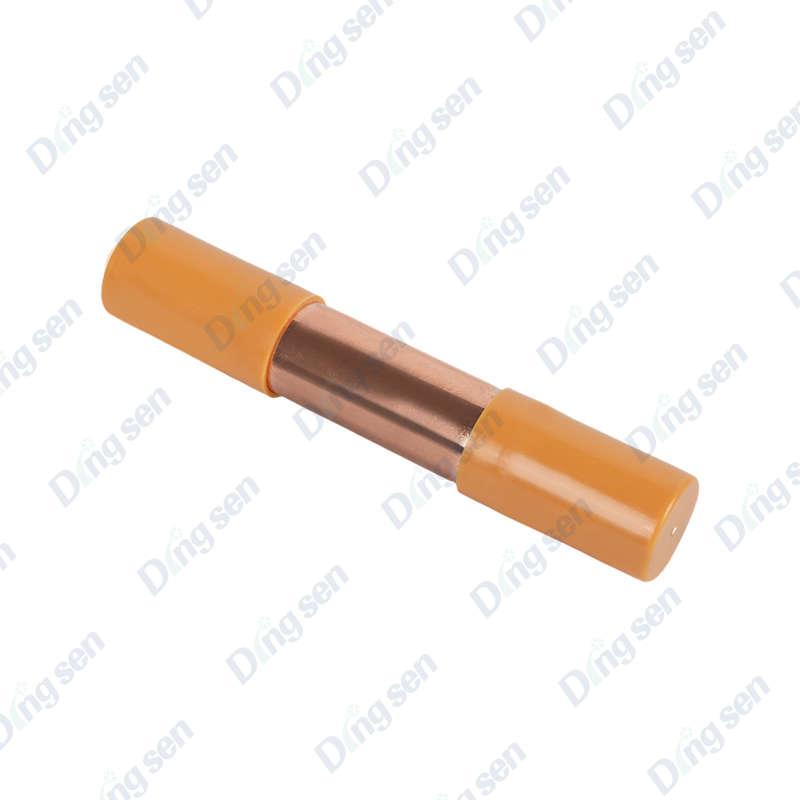

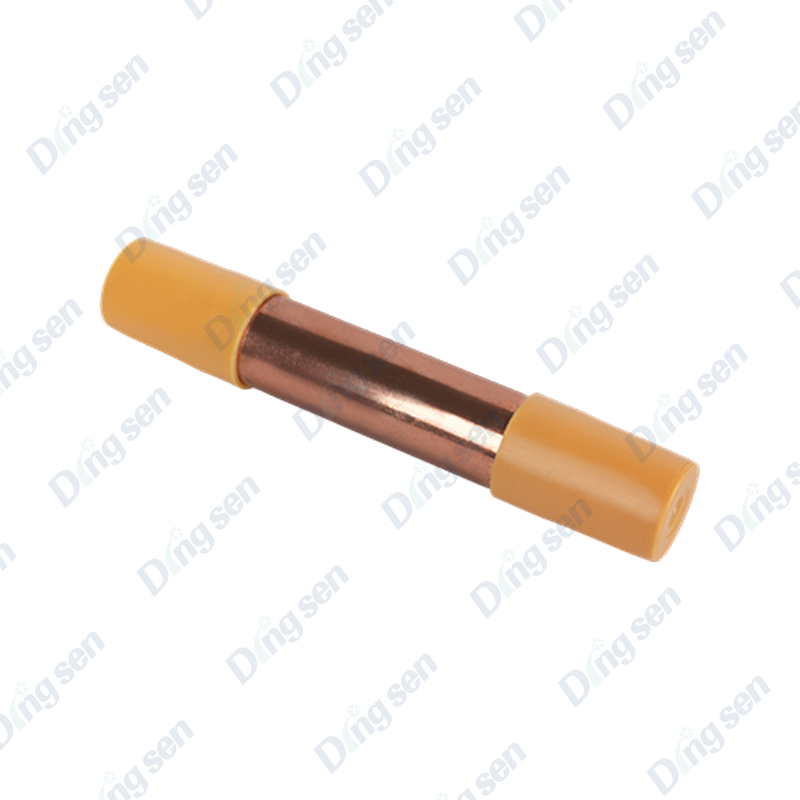

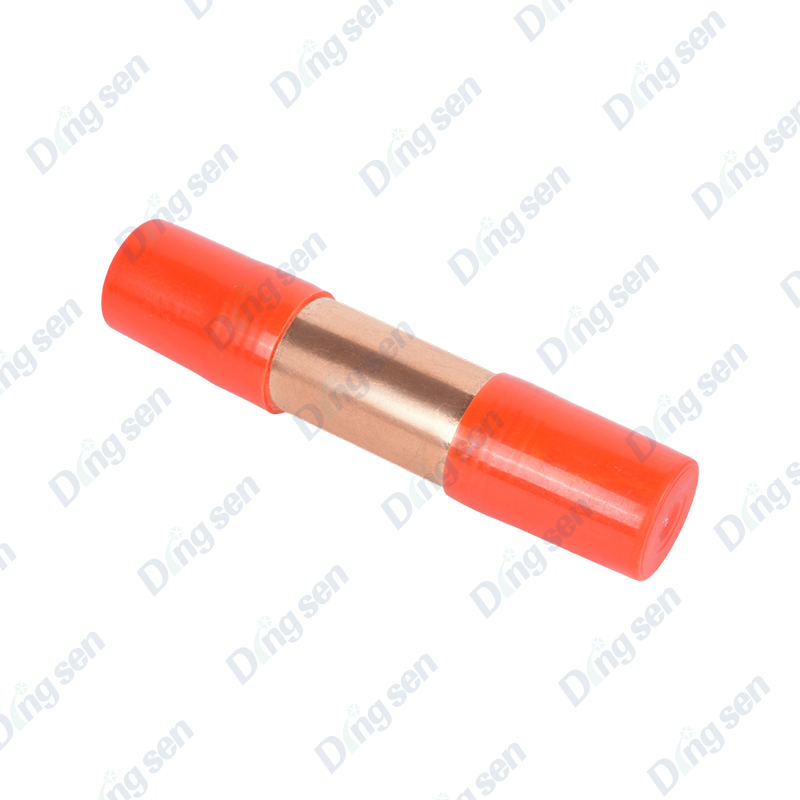

READ MORECopper drying filter

The copper drying filter is a specialized purification component for refrigeration systems. Constructed of high-quality copper, it integrates impurity filtration and moisture adsorption, preventing pipe blockage and component corrosion, ensuring refrigerant purity.

It is suitable for liquid lines in refrigeration equipment, air conditioners, and refrigeration units, meeting purification needs in various scenarios.

Precision machining and pressure and airtightness testing ensure stable performance.

Service includes pre-sales selection and after-sales maintenance guidance. Advantages include corrosion resistance, strong purification, wide compatibility, and easy installation.

As the core purification component of the refrigeration system, the copper drying filter's core advantages lie in its material properties and functional integration: the shell is made of high-purity, high-quality copper, which has excellent corrosion resistance, thermal conductivity, and pressure resistance. It can withstand long-term erosion by refrigerants and refrigeration oil, and is suitable for a wide operating temperature range of -40°C to 120°C, avoiding the problems of rust and deformation of traditional metal shells. The internal integration of high-precision composite filter material and high-efficiency molecular sieve desiccant can accurately intercept impurities such as metal debris and welding slag with a filtration accuracy of micron level. The desiccant can strongly absorb residual moisture in the pipeline, preventing moisture from reacting with refrigerant to generate acidic substances that corrode the compressor and clog the capillaries, thus realizing "filtration + drying" integrated purification. The copper housing offers excellent thermal conductivity, helping to stabilize refrigerant temperature and improve system heat exchange efficiency. Compatible with mainstream refrigerants such as R22, R410A, and R32, it accommodates pipe sizes from DN6 to DN40, eliminating the need to select individual pipe sizes based on the medium or diameter, reducing inventory costs. Its compact structure supports various mounting methods, including screw and welded connections, to accommodate diverse piping layouts. Applications include a wide range of liquid pipelines in residential air conditioners, commercial refrigerated display cabinets, supermarket cold chain equipment, industrial cold storage, and large refrigeration units. It provides reliable purification for various refrigeration systems, helping to improve unit operational stability, extend the life of core components, and reduce the frequency of repairs.

-

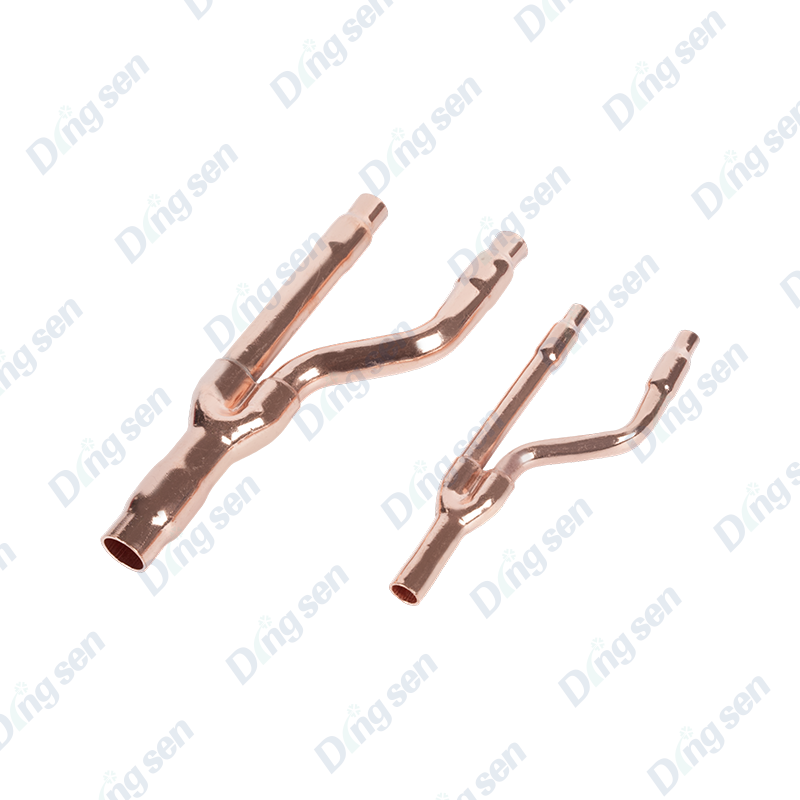

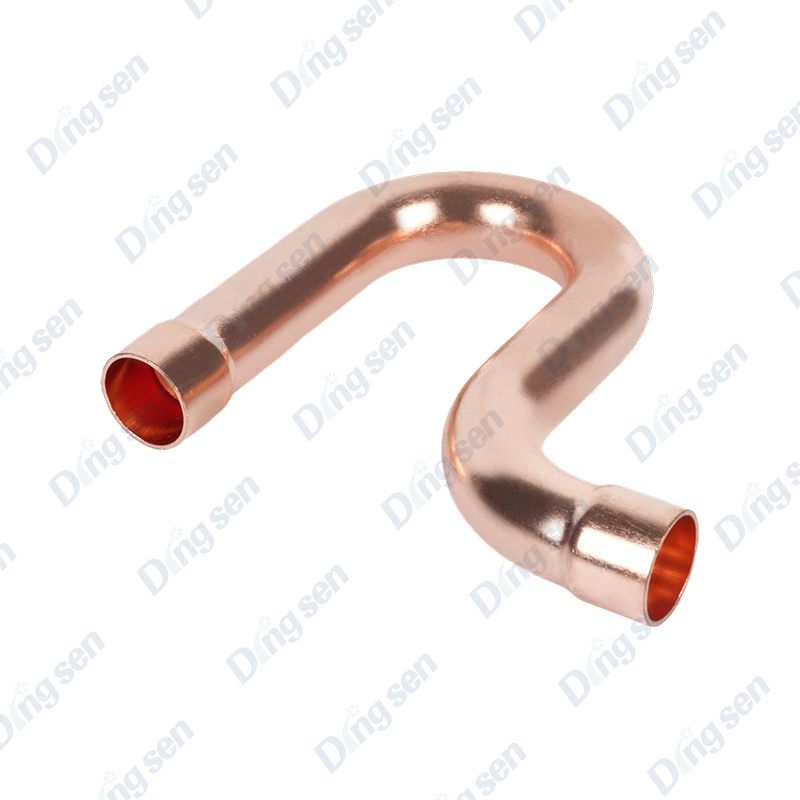

Copper Branch pipe series are core components for refrigerant distribution in re...

-

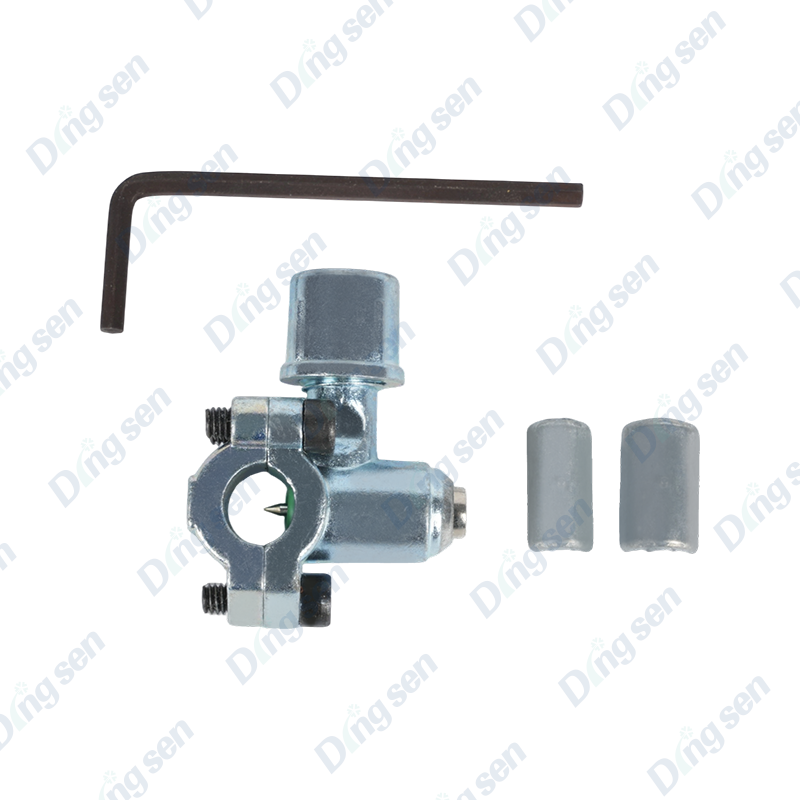

The copper pipe puncture valve is a specialized valve for copper pipe system mai...

-

Copper pipe fittings are core connectors for air conditioning and refrigeration ...

-

The copper tube expander is a specialized tool for copper tube connection. It ex...

-

A copper tube bender is a specialized tool for forming copper tubes. It bends co...

-

Refrigeration drying filter cylinder are drying and purification components in r...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى