In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

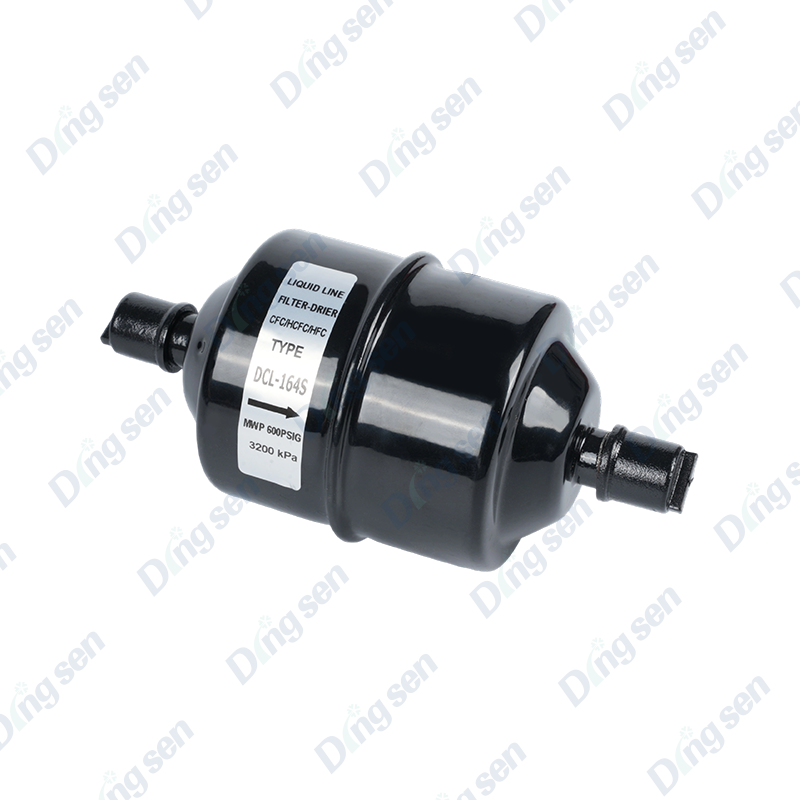

READ MORERefrigeration drying filter cylinder

Refrigeration drying filter cylinder are drying and purification components in refrigeration systems, combining impurity filtration and moisture absorption to prevent corrosion and clogging of piping components and ensure clean media.

Suitable for liquid pipelines in refrigeration, air conditioning, and refrigeration units.

Production utilizes corrosion-resistant housings, high-efficiency desiccants, and filter media, tested for pressure resistance and drying efficiency.

Pre-sales selection and after-sales maintenance guidance are provided. Advantages include strong purification, wide compatibility, long life, and easy installation.

Applications

Filter cartridges with replaceable cartridges are used in liquid and suction lines in refrigeration, refrigeration, and air conditioning systems. They effectively remove impurities, moisture, and acidic substances from the system, thereby better protecting the compressor and extending its service life. Key Features

Durable, rugged steel housing with sturdy copper or carbon steel ports and 1/4" NPT inspection ports for extremely low pressure drop when fully open. Rust-resistant flanges, patented filter element holder, and galvanized springs facilitate easy filter element replacement. Corrosion-resistant epoxy electrostatically sprayed for durability in any environment. For liquid line filters, install D-48/H-48 or D-100/H-100 solid desiccant filters to effectively filter impurities, absorb moisture, and absorb acid. For suction line filters, install X-48/X-100 fiber filter elements or F-48/F-100 stainless steel filter elements to effectively filter impurities and prevent contaminants from entering the compressor.

Technical Parameters

Maximum operating pressure: 3.5 MPa (35 Bar). Select the filter model based on system cooling capacity, refrigerant type, humidity, or acid removal requirements. Select the filter interface based on the required system interface, then select the appropriate size based on system cooling capacity.

-

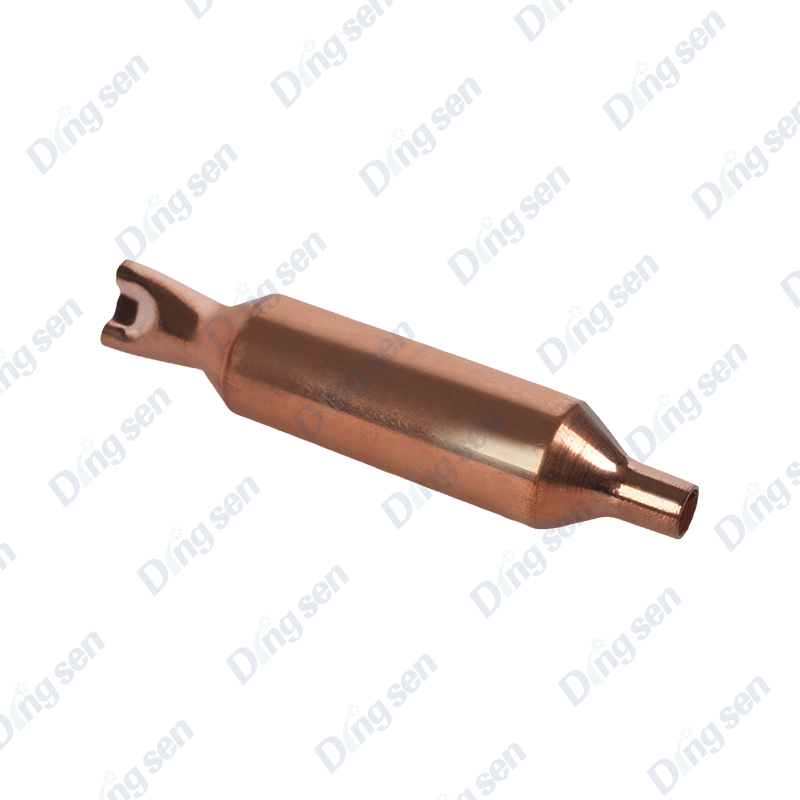

The copper drying filter is a specialized purification component for refrigerati...

-

The refrigeration oil manual pump is a specialized tool for filling refrigeratio...

-

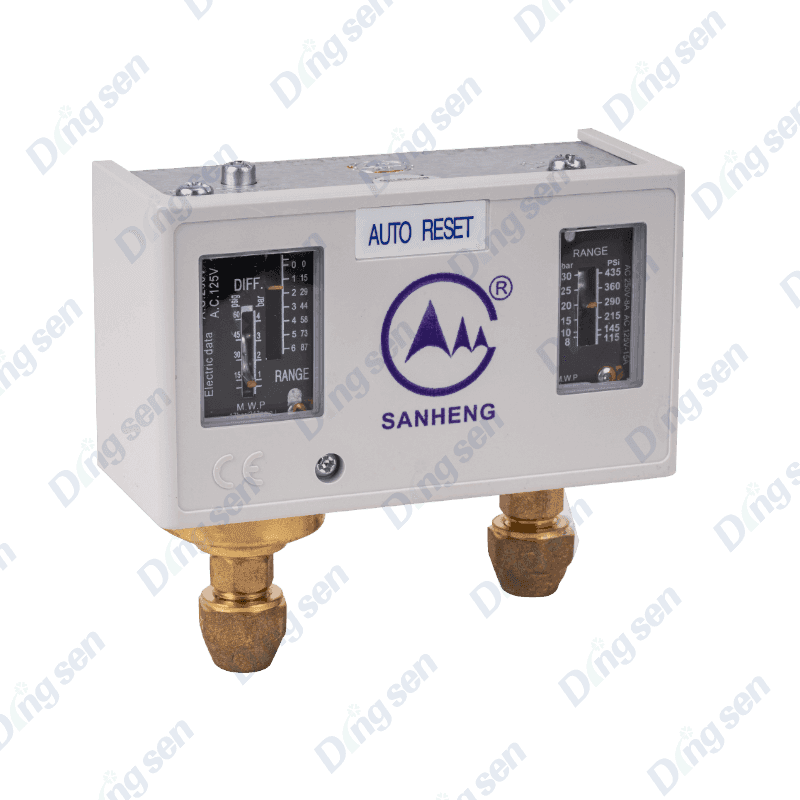

The refrigeration pressure controller features a rectangular box with a white, c...

-

-

-

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى