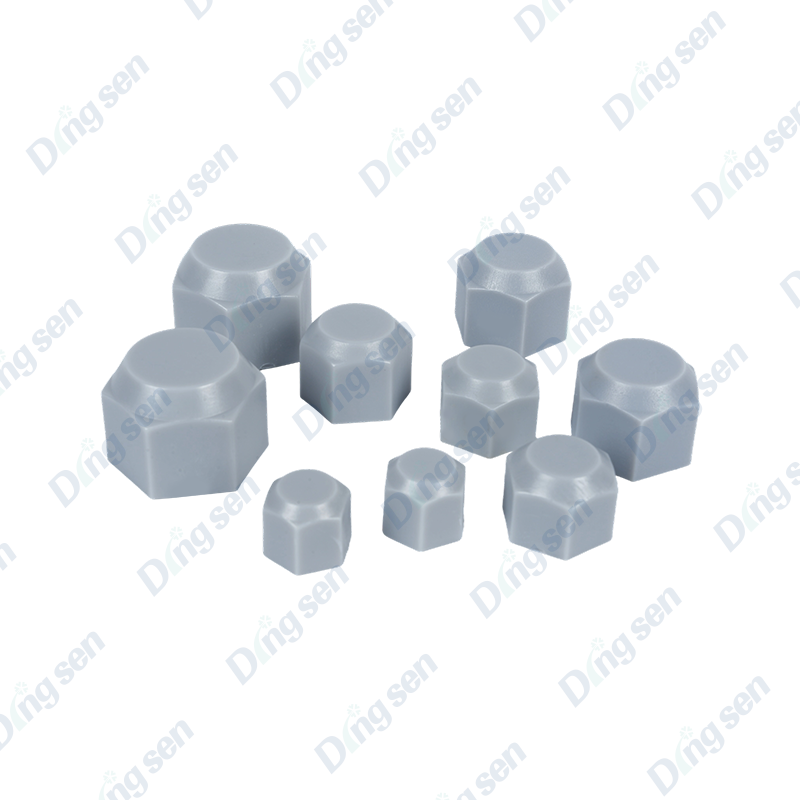

In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

READ MOREO-ring kit

O-ring kits are universal sealing components with an annular structure. They rely on compression deformation to fill the sealing gap, preventing gas and liquid leakage, ensuring stable sealing performance in equipment and adaptable to a variety of sealing scenarios.

They are used in hydraulic and pneumatic systems, as well as sealing pipes, valves, and joints in household appliances, automobiles, and chemical equipment.

They are manufactured using oil-resistant and corrosion-resistant rubber (such as nitrile and fluororubber), and undergo compression molding and seal testing to ensure reliable performance.

Our service includes selection and installation guidance. Our advantages include excellent sealing, wide compatibility, low cost, and long service life. O-rings are common sealing components in the industrial field. Their core advantages are "high adaptability and long-lasting sealing." They are custom-made in a variety of materials, including nitrile rubber (NBR), fluororubber (FKM), and silicone rubber (VMQ). Nitrile versions offer excellent oil resistance, fluororubber versions offer high and low temperature resistance (-20°C to 200°C) and strong corrosion resistance, and silicone rubber versions are food-grade certified. Through a one-piece compression molding process, the ring body tolerance is controlled to ±0.05mm, with a compression set rate of ≤20%. After compression, they tightly fill the sealing gap, achieving a gas and liquid leakage rate of less than 0.01mL/h, ensuring long-term stable operation of the equipment. Some models feature a dust-proof coating or reinforced frame to enhance wear and extrusion resistance. Custom colors and hardness are available to meet the visual identification and sealing pressure requirements of specific operating conditions. Application scenarios widely cover hydraulic and pneumatic systems (oil cylinders, cylinder seals), household appliances (air conditioning valves, washing machine water inlets), automotive fields (engine oil pans, gearbox interfaces), chemical equipment (reactor pipelines, valve seals) and food machinery (juicers, sterilization equipment). Whether it is static sealing under high-pressure conditions or dynamic sealing in reciprocating motion, it can effectively perform the sealing function, combining low cost and high reliability, becoming a core component of sealing solutions in various industries.

-

Oil-filled pressure gauges are specialized pressure monitoring instruments. Buil...

-

The Nitrogen Pressure Retention Kit is a pipeline leak testing tool set that inc...

-

The Spring Tube Bender is a small-diameter tube-forming tool. Using a spring's e...

-

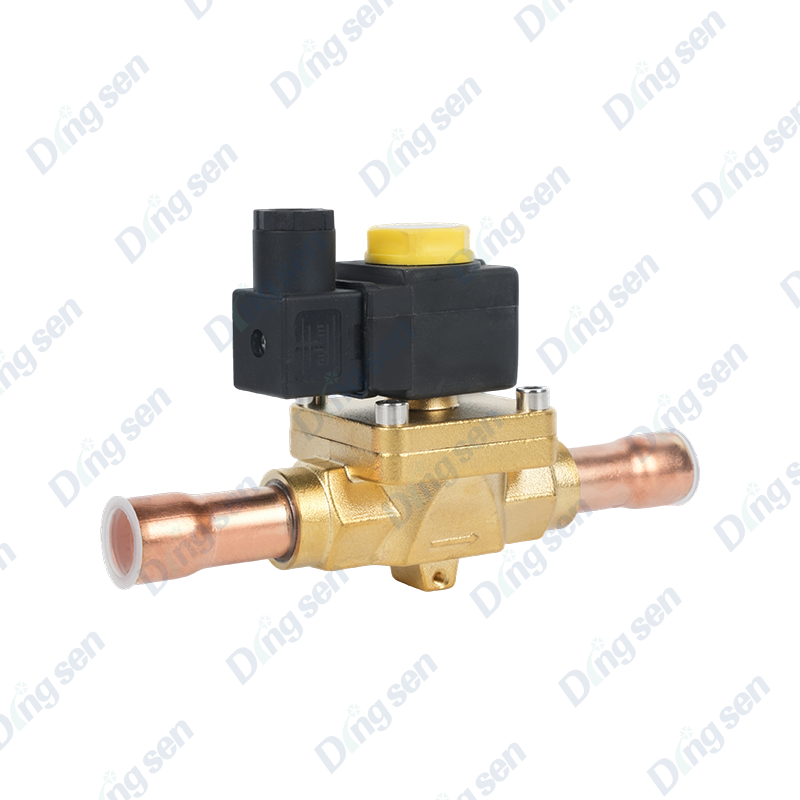

EVR solenoid valves are key components in refrigeration and air conditioning, co...

-

Air conditioning plastic nuts are lightweight seals for connecting copper pipes ...

-

The air conditioning refrigerant charging adapter is an adapter fitting for air ...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى