In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

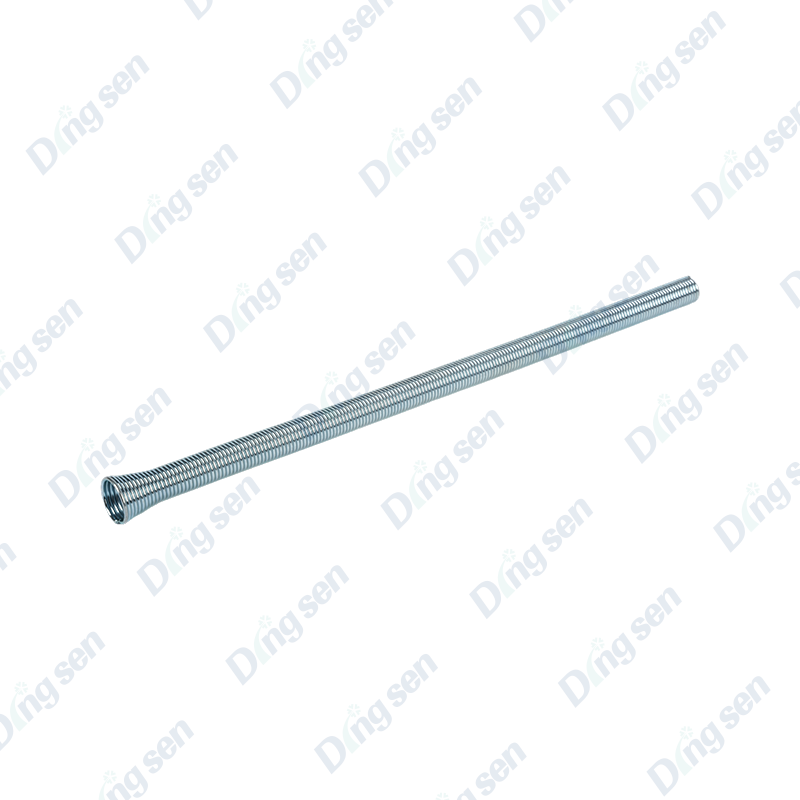

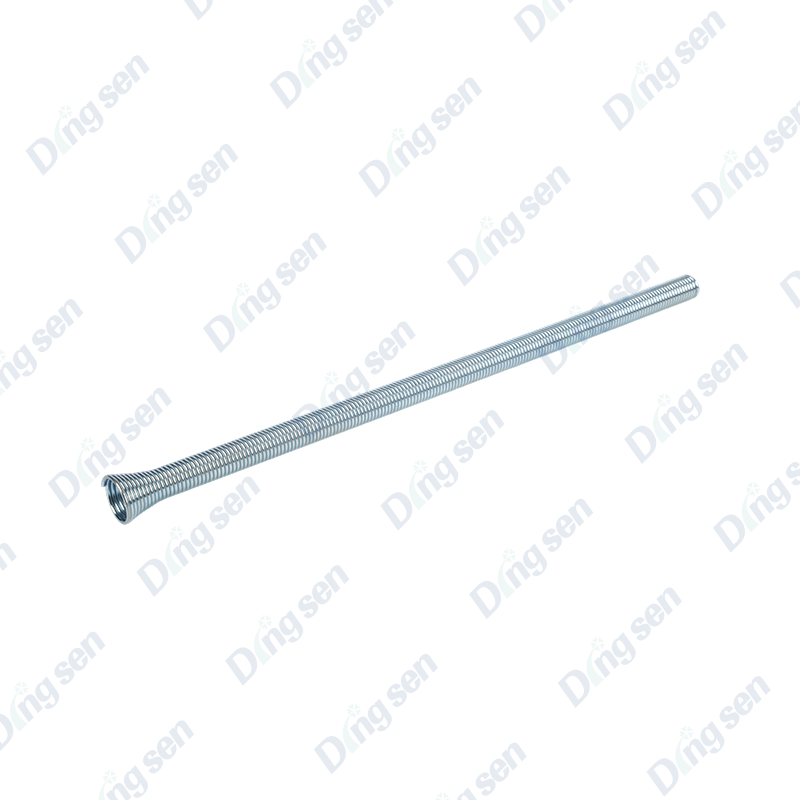

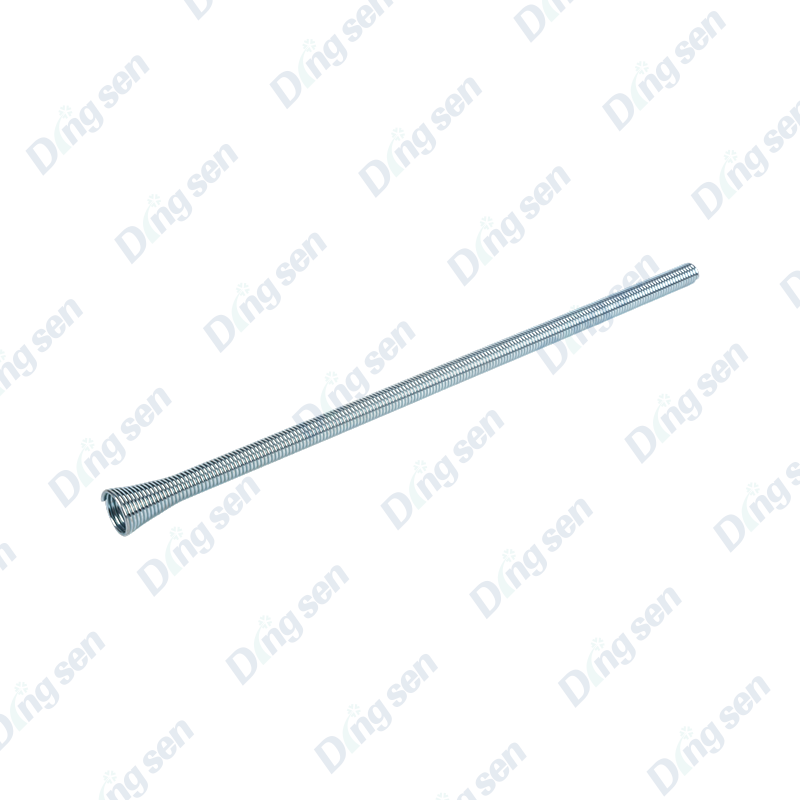

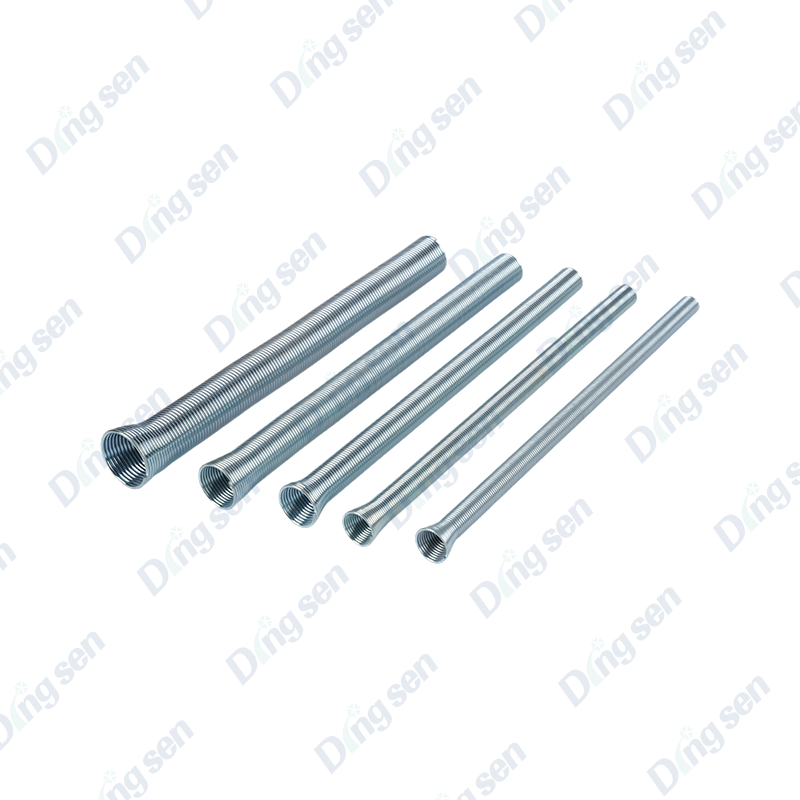

READ MORESpring tube bender

The Spring Tube Bender is a small-diameter tube-forming tool. Using a spring's elastic support, it can manually bend copper and aluminum tubes ranging from 3mm to 12mm, preventing cracking and cracking at the bend, ensuring smooth pipe flow, and is suitable for working in confined spaces.

It is used for small-diameter pipe installation in air conditioners and refrigerators, as well as for forming pipes for plumbing and appliance repair.

It is manufactured from highly elastic manganese steel and tempered to ensure stable springback and durability.

The service includes selection guidance. Advantages include portability, lightweight, easy operation, damage-resistant tube protection, and compatibility with small pipe diameters.

The Spring tube bender is a specialized hand tool for precision forming small-diameter tubes. Its core advantages are "lightweight and portable + damage-resistant protection." It's made from highly elastic manganese steel wire through a dual cold-drawn and tempered process. The spring pitch strictly matches the inner diameter of 3mm-12mm copper tubes, aluminum tubes, thin-walled stainless steel tubes, and other tubes. During bending, the spring tightly wraps around the inner wall of the tube, offsetting external forces through elastic support to effectively prevent dents, wrinkles, or cracks at the bend, ensuring the smooth flow of the inner diameter of the pipe (inner diameter shrinkage rate ≤3%). It requires no external power and is suitable for operations in confined spaces such as inside air conditioner outer casings and next to refrigerator compressors. Core selling points address practical needs: over 10 models are available by pipe specification, precisely matching different pipe diameters and offering flexible bending angle control from 0° to 180°. The spring surface is chrome-plated for rust prevention, resistant to corrosion in humid environments, and has a service life of over 500 bending operations. Weighing only 50-150g, it's portable and can be operated by a single person, requiring no specialized training. Select models feature a non-slip handle for a more secure grip, preventing slippage and damage during bending. Applications include the installation and repair of small connecting pipes for indoor and outdoor air conditioners, refrigerator capillary tubing, household plumbing, and internal piping for small appliances (such as coffee makers and water heaters). It's particularly well-suited for on-site pipe forming during repair visits. It meets the demands of precision pipe bending while addressing the limitations of large pipe bending tools in confined spaces, significantly improving the flexibility and efficiency of small-diameter pipe processing.

-

A copper tube bender is a specialized tool for forming copper tubes. It bends co...

-

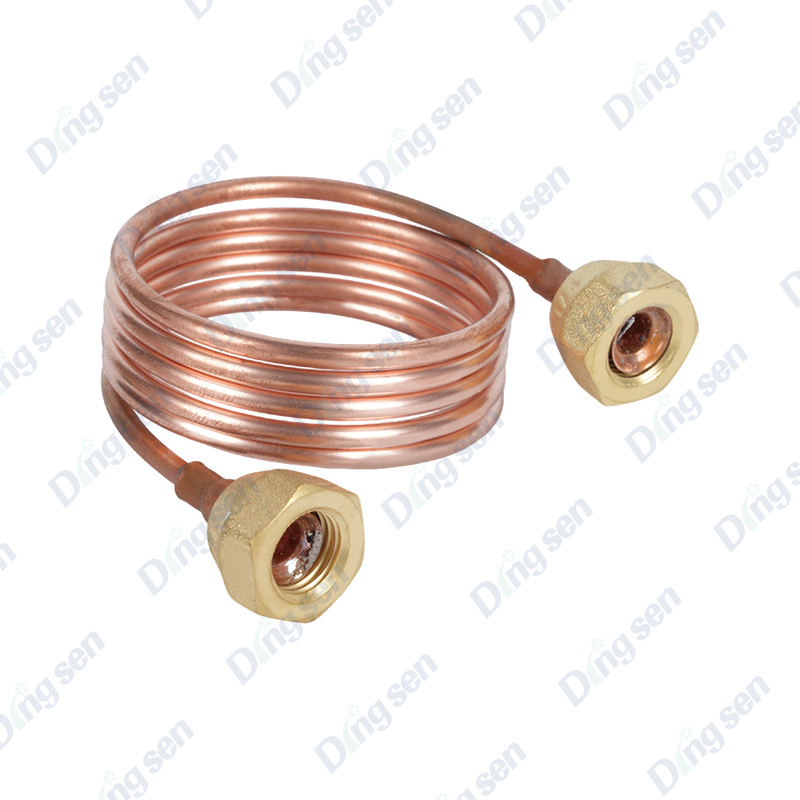

Copper capillary tube assemblies are core throttling components in refrigeration...

-

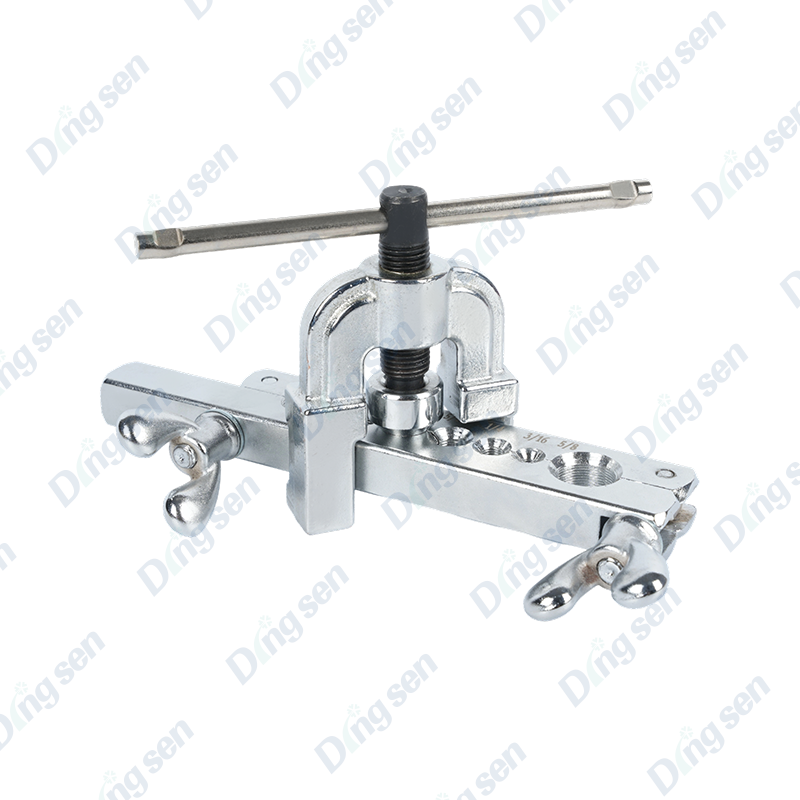

The air conditioning copper tube reamer is a specialized tool for connecting cop...

-

The copper tube expander is a specialized tool for copper tube connection. It ex...

-

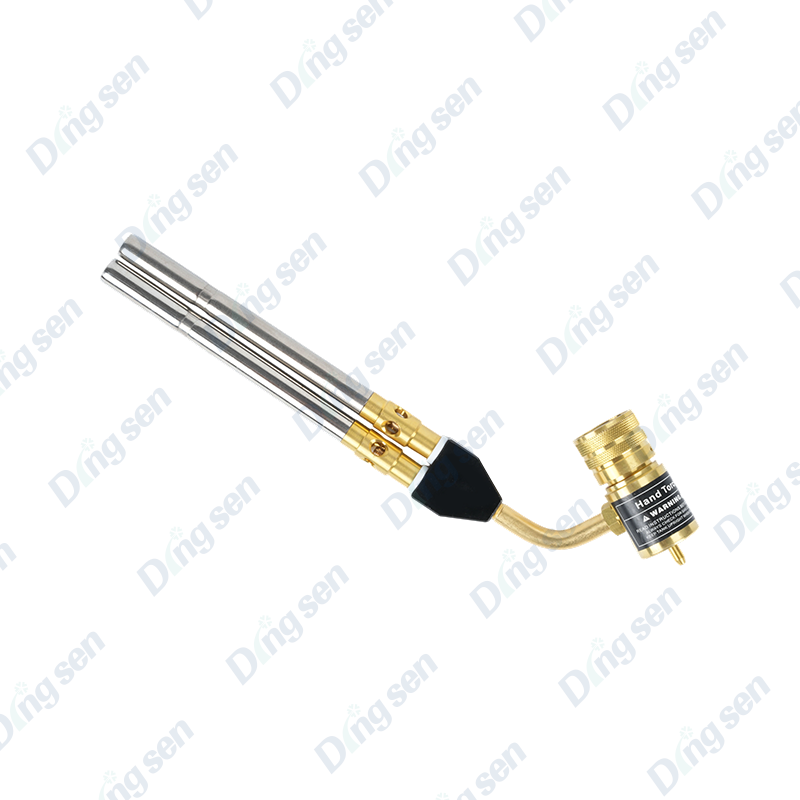

The dual tube MAPP welding gun is designed for scenarios such as air conditionin...

-

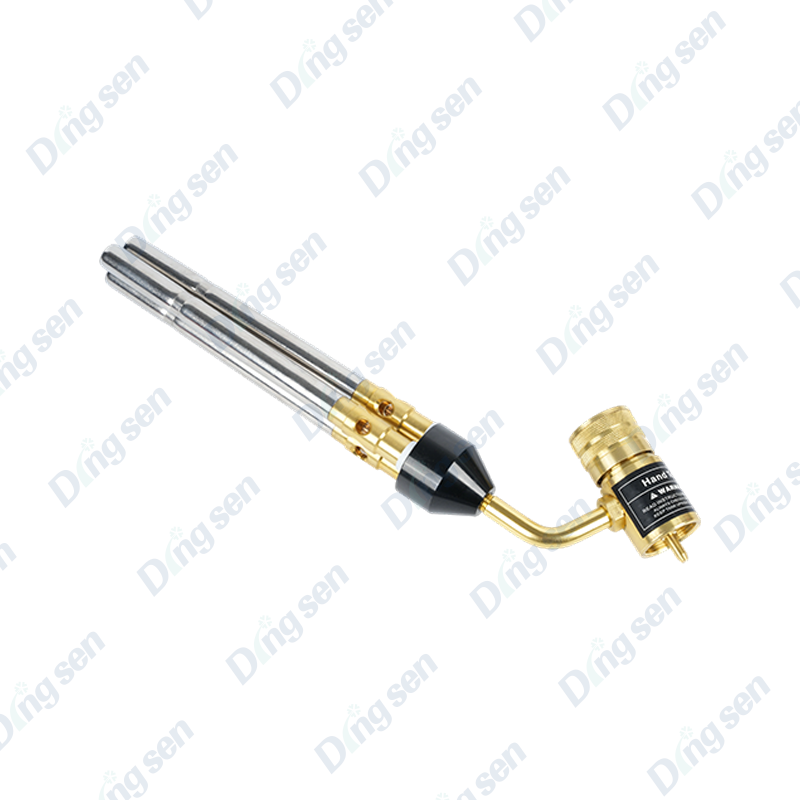

The three tube high-temperature welding gun is designed specifically for high-te...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى