In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

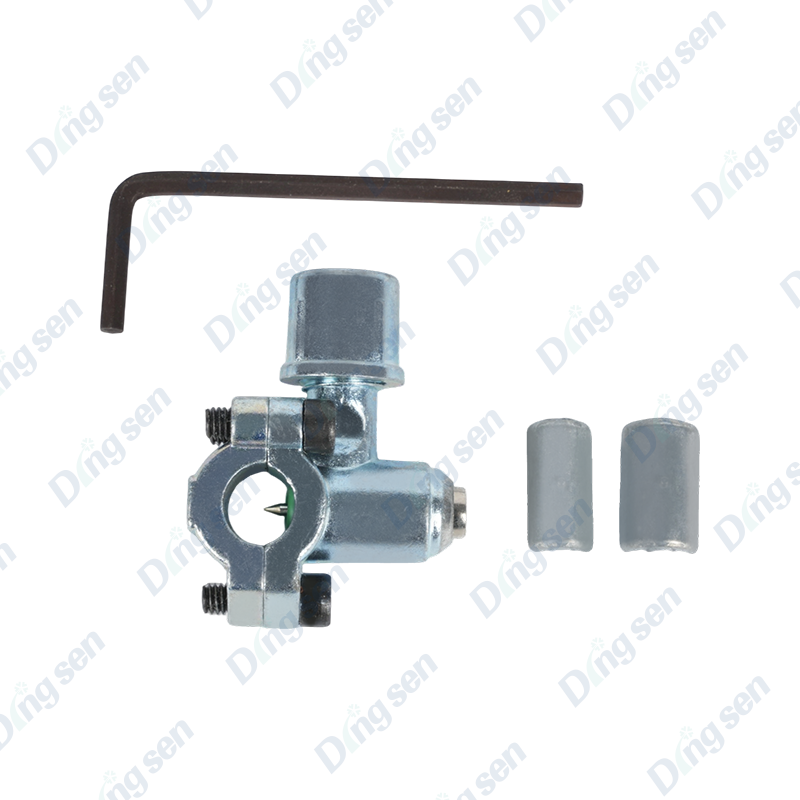

READ MORECopper pipe puncture valve

The copper pipe puncture valve is a specialized valve for copper pipe system maintenance. It punctures the copper pipe wall to establish a testing/filling channel. It provides both sealing and one-way control functions, allowing operation without interrupting the line, thus safeguarding system integrity.

It is suitable for copper pipes in air conditioners and refrigeration units, meeting the needs of refrigerant filling and pressure testing.

Manufactured with corrosion-resistant copper and precision valve cores, it undergoes puncture strength and sealing tests to ensure reliable performance.

This service includes pre-sales selection and installation guidance. Advantages include no pipe interruption, excellent sealing, easy operation, and wide compatibility. The copper pipe puncture valve is an innovative, purpose-built valve for refrigeration system copper pipe maintenance. Its core advantages lie in its "no pipe cutouts required + efficient sealing control." Its built-in, high-strength hardened steel puncture needle can precisely pierce copper or brass pipes with a thickness of 1.0mm to 2.0mm. This allows for quick access for refrigerant filling, pressure testing, or system leak detection without interrupting the pipe. This eliminates the pipe damage and secondary contamination associated with traditional pipe cutouts, maximizes copper pipe system integrity, and significantly reduces maintenance costs and time. The valve body is cast from high-purity, corrosion-resistant copper, featuring a refrigerant-resistant fluororubber seal and a precision one-way valve core. After puncture, tightening the valve stem creates a double seal, ensuring long-term resistance to refrigerant corrosion and operating temperatures ranging from -50°C to 120°C. It accepts mainstream copper pipe sizes from DN6 to DN25 and features an adjustable clamping device, eliminating the need to select pipes by diameter and accommodating pipes of varying wall thicknesses. Operation requires no specialized equipment; puncture and sealing can be performed manually by a single operator. After puncture, the valve can be opened and closed repeatedly, meeting system maintenance requirements. Its application scenarios encompass a wide range of refrigeration equipment containing copper pipes, including residential and commercial air conditioners, industrial refrigeration units, refrigeration and freezing equipment, and heat pump systems. Whether replenishing refrigerant during commissioning of new units, pressure testing existing equipment, or detecting leaks during troubleshooting, the valve is highly effective. It is particularly suitable for maintenance in high-altitude and confined spaces where pipe disconnection is inconvenient, providing a convenient and reliable solution for refrigeration system maintenance.

-

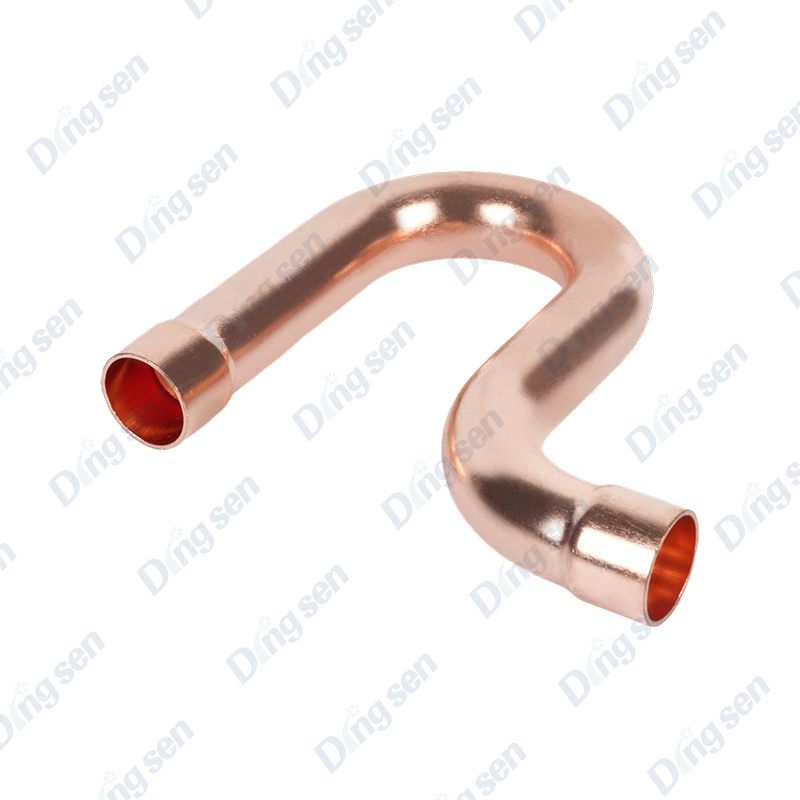

Copper pipe fittings are core connectors for air conditioning and refrigeration ...

-

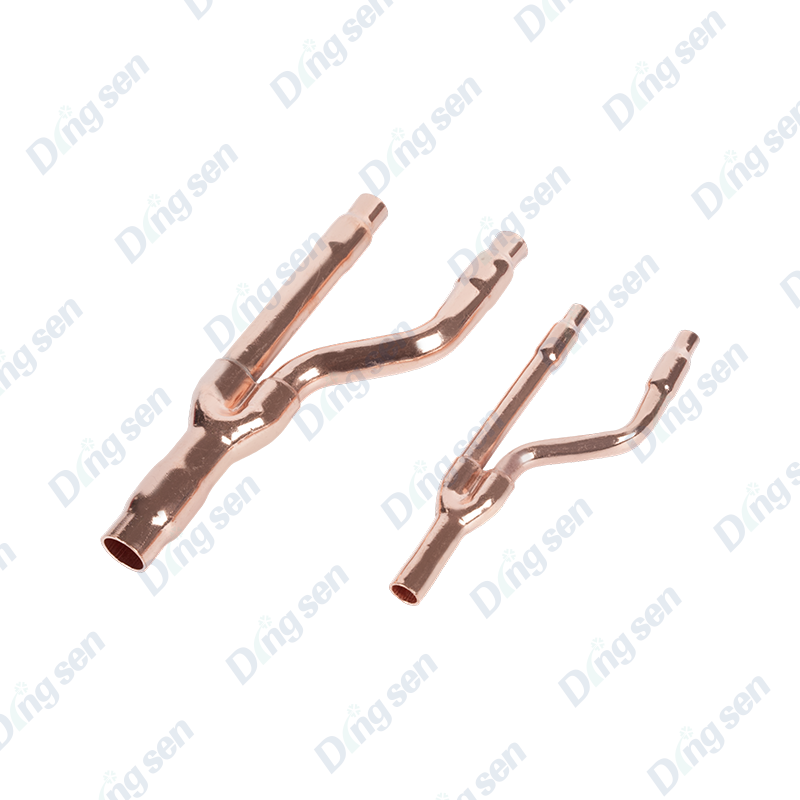

Copper Branch pipe series are core components for refrigerant distribution in re...

-

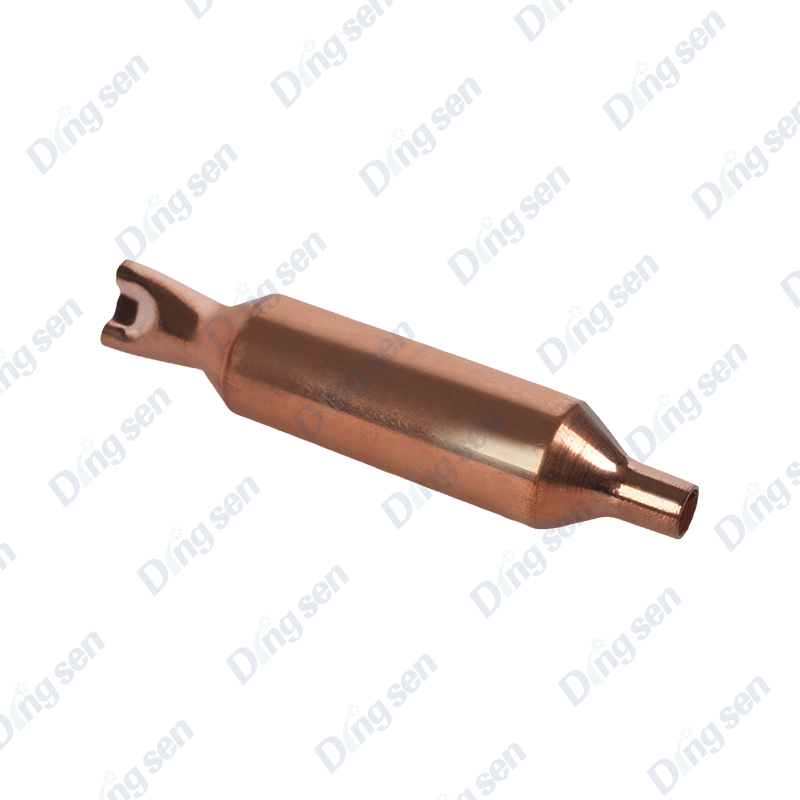

The copper drying filter is a specialized purification component for refrigerati...

-

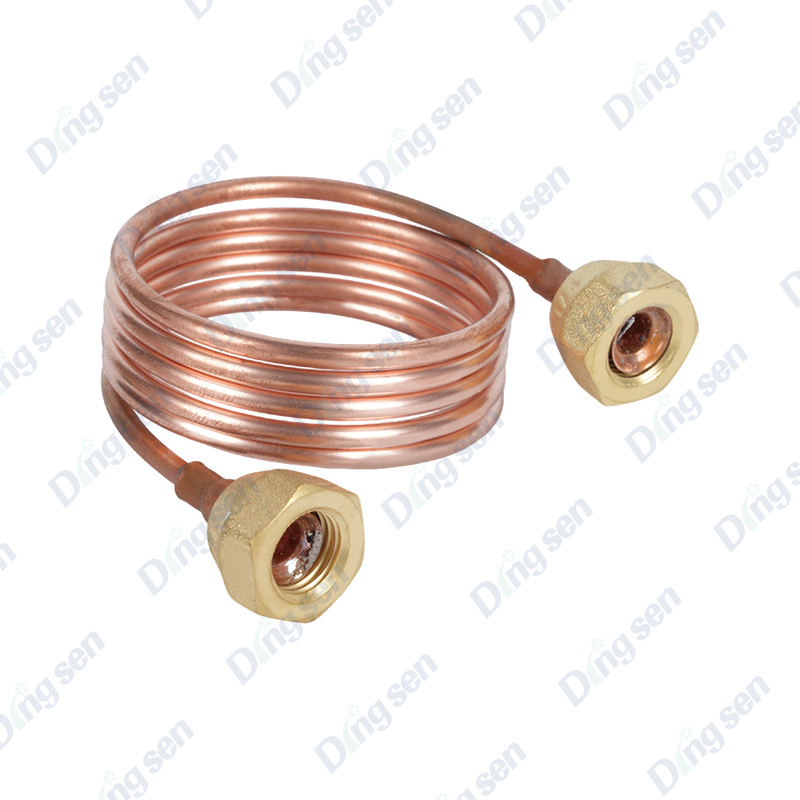

Copper capillary tube assemblies are core throttling components in refrigeration...

-

A copper tube bender is a specialized tool for forming copper tubes. It bends co...

-

The copper tube expander is a specialized tool for copper tube connection. It ex...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى