In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

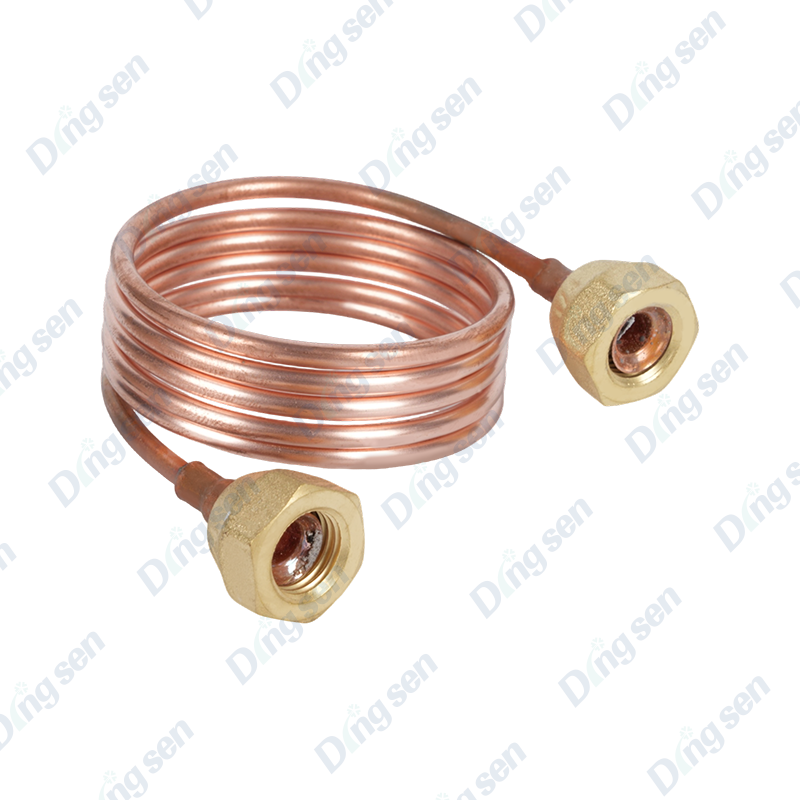

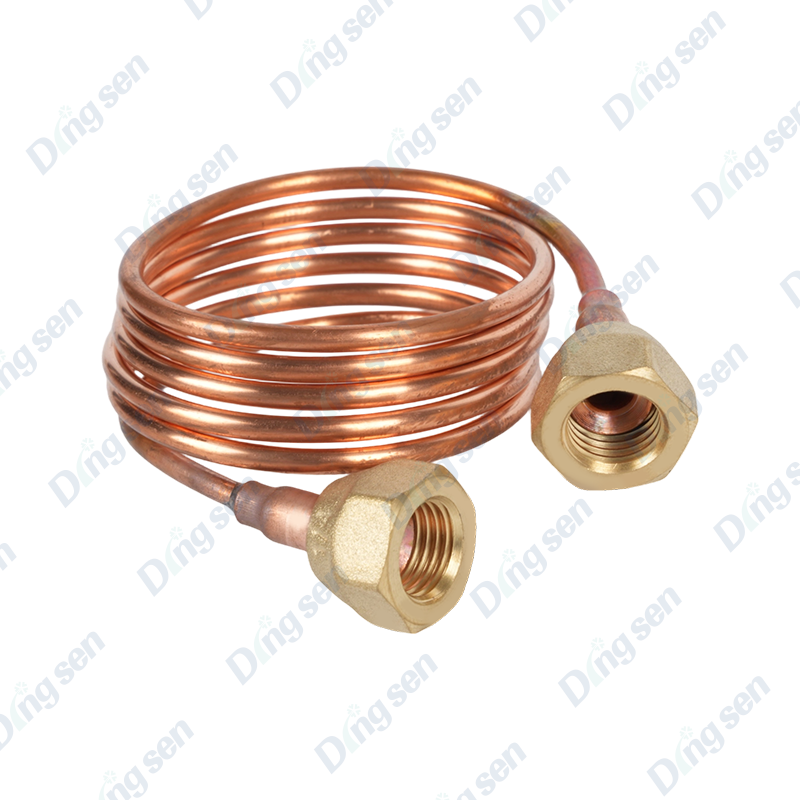

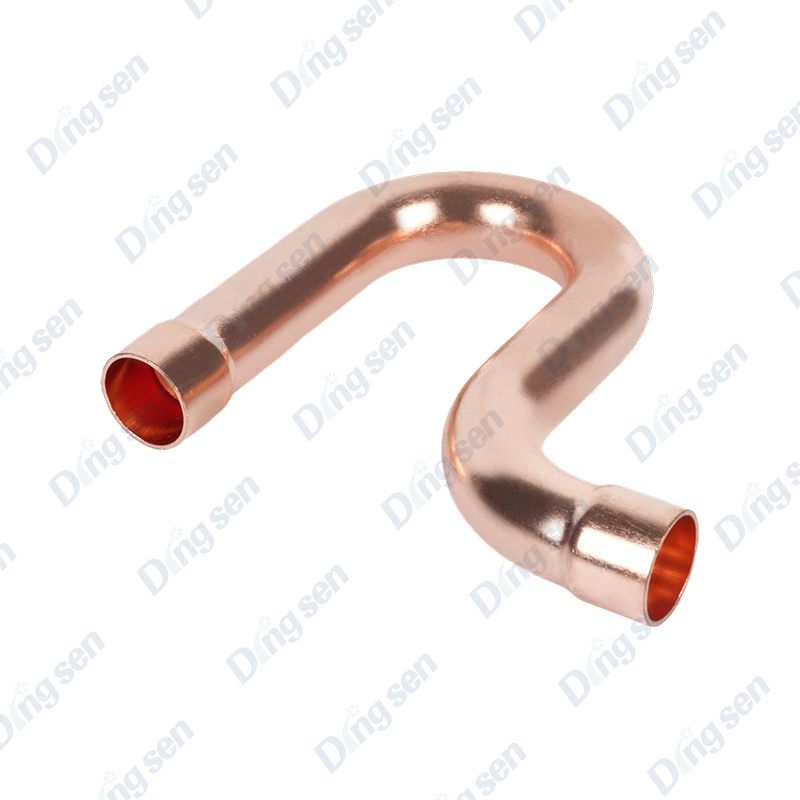

READ MORECopper capillary tube assembly

Copper capillary tube assemblies are core throttling components in refrigeration systems. Crafted from high-precision copper tubes, they achieve refrigerant gas-liquid conversion through flow limiting and pressure reduction, ensuring efficient heat transfer.

Suitable for throttling piping in air conditioners, refrigeration equipment, and refrigeration units, they meet the heat transfer needs of various scenarios.

Precision cutting, bending, and pressure testing ensure dimensional accuracy and stable performance.

Service includes pre-sales selection and after-sales installation guidance. Advantages include excellent thermal conductivity, strong corrosion resistance, wide compatibility, and long service life.

Copper capillary tube assemblies are key throttling components in refrigeration systems. Made from high-purity copper tubes, they are precision-machined into multiple sets of adaptable tubes. Through precise flow limiting and pressure reduction, they convert high-pressure liquid refrigerant into a low-pressure mist, providing optimal medium conditions for heat transfer in the evaporator. They are a key component in ensuring system heat transfer efficiency and operational stability. Its core advantages are significant: copper offers excellent thermal conductivity, enabling rapid temperature transfer and facilitating efficient phase change of refrigerants. It is also resistant to corrosion from refrigerants and refrigeration oils, resisting rust or embrittlement over long periods of use, and boasts a service life far exceeding that of ordinary metal piping. Precision cutting and bending processes ensure diameter tolerances within ±0.05mm. The length and bend angle of each capillary tube set are precisely matched to system requirements, ensuring consistent throttling and avoiding uneven heat transfer caused by dimensional deviations. Multiple customizable combinations can be tailored to the cooling capacity and piping layout of air conditioners, refrigeration equipment, and refrigeration units, adapting to single-system multi-evaporator or complex piping scenarios. Eliminating the need for additional throttling components, the integrated design simplifies system structure and reduces installation and maintenance costs. Applications encompass a wide range of throttling piping applications, including residential central air conditioners, commercial refrigerated display cabinets, supermarket cold chain units, industrial cold storage, and small refrigeration equipment. Whether it's efficient temperature control in residential applications or stable cooling in commercial and industrial settings, this system provides reliable throttling support, improving overall system efficiency and reducing energy losses.

-

The copper tube expander is a specialized tool for copper tube connection. It ex...

-

A copper tube bender is a specialized tool for forming copper tubes. It bends co...

-

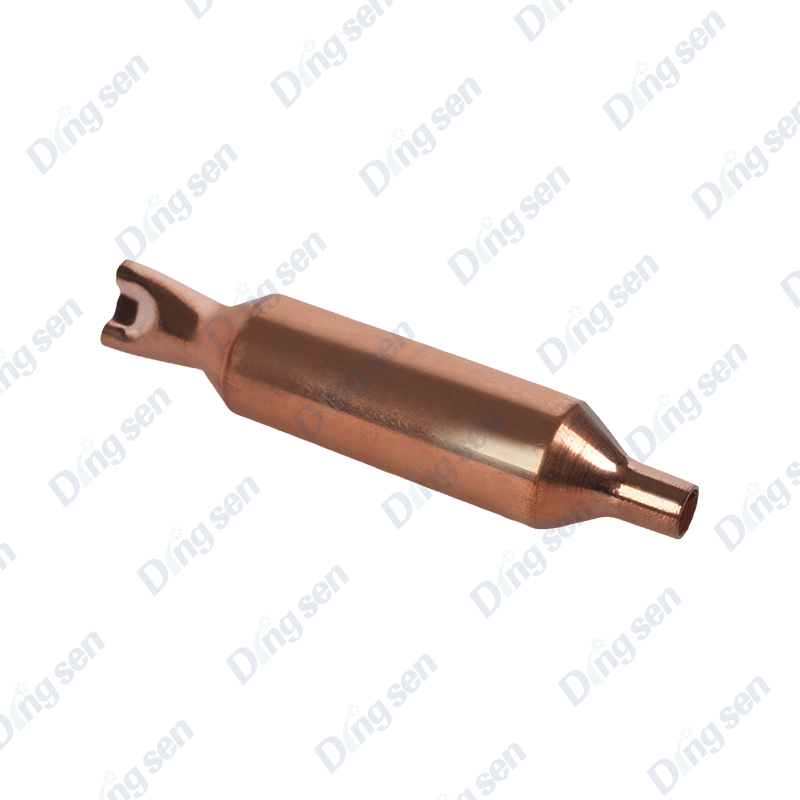

The copper drying filter is a specialized purification component for refrigerati...

-

Copper pipe fittings are core connectors for air conditioning and refrigeration ...

-

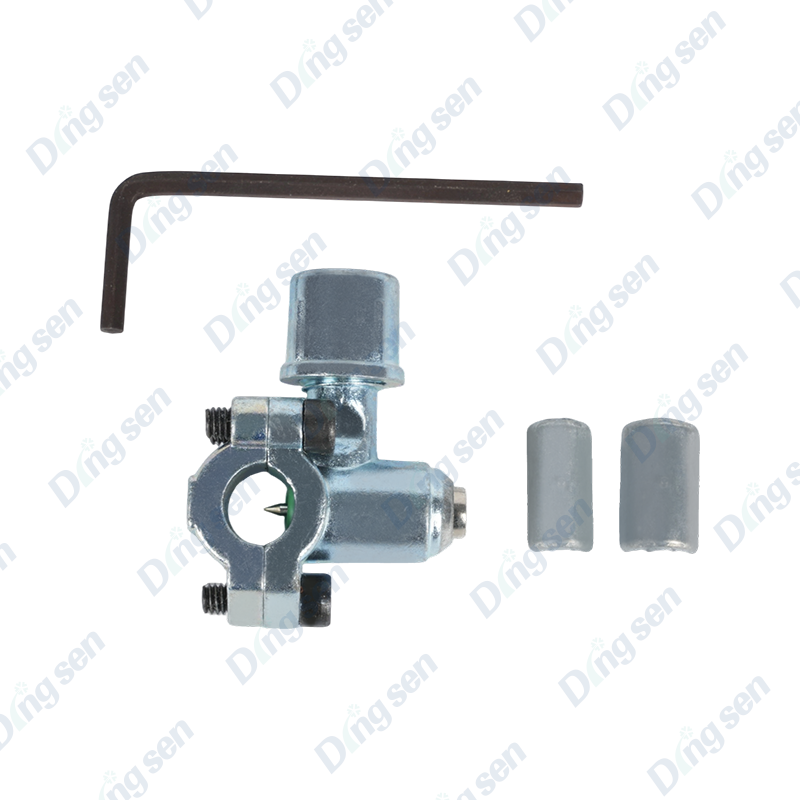

The copper pipe puncture valve is a specialized valve for copper pipe system mai...

-

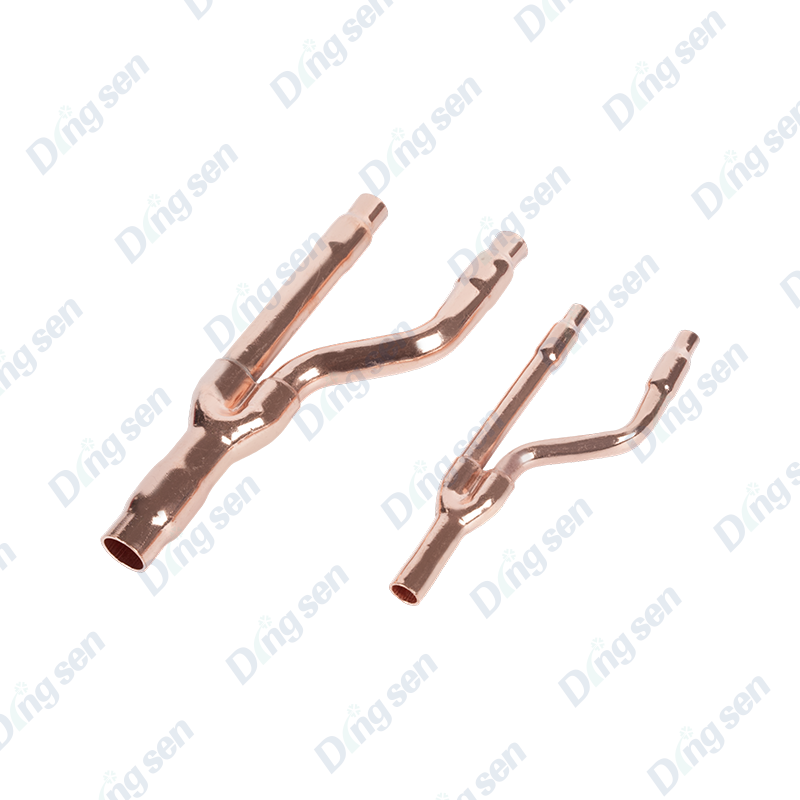

Copper Branch pipe series are core components for refrigerant distribution in re...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

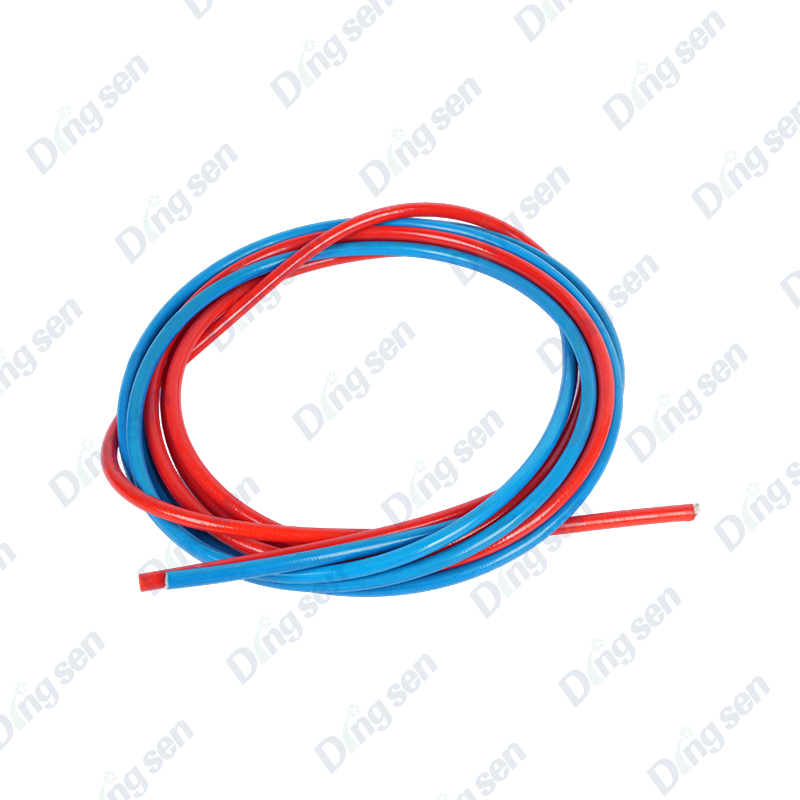

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى