The Air Conditioning Copper Pipe Connector, with its efficient and reliable connection performance, is gradually replacing traditional welding and crimping methods, becoming the ideal connection solution for modern air conditioning systems. Compared to traditional methods, the Air Conditioning Coppe...

READ MORECopper tube expander

The copper tube expander is a specialized tool for copper tube connection. It expands the ends of copper tubes into a sealed, standard-compliant flare, ensuring tight connections between fittings, preventing leakage, and ensuring efficient operation of the piping system.

It is suitable for copper tube installation and repair in air conditioning, refrigeration, and plumbing systems, meeting the needs of connecting new pipes or repairing existing pipes.

The tool utilizes high-strength alloy dies, undergoes precision machining, and undergoes wear resistance testing to ensure precise expansion and a long service life.

The service includes pre-sales selection and operation guidance. Advantages include accurate expansion, ease of operation, a wide range of adaptability, and strong sealing.

The copper tube expander is a specialized tool for achieving sealed copper tube connections. Its core advantages are "high-precision flaring + full-scenario adaptability." Utilizing a one-piece forged chrome-vanadium steel flare die treated with a nano-level wear-resistant coating, it accurately expands copper tubes ranging from 6mm to 28mm into a standard 37° flare, ensuring a seamless fit when connecting to fittings, ensuring a tight and efficient piping system. Some models come with a multi-specification mold set, compatible with both thin-walled and thick-walled copper tubes, eliminating the need for separate purchases. An integrated ratchet drive structure applies uniform force in one direction to prevent deformation and cracking of copper tubes, while the labor-saving design allows for easy single-person operation. A graduated positioning assembly allows for flaring depth control with an accuracy of ±0.1mm, preventing seal failure caused by over-expansion. The handle is wrapped in non-slip rubber for a secure grip and insulation from mold heat, enhancing operational safety. Applications encompass air conditioning and refrigeration piping, industrial refrigeration equipment, household water heating systems, gas pipelines, and other fields. Whether connecting copper pipes during new unit installation, repairing ports during maintenance of existing pipes, or constructing batches of pipes for commercial projects, these flaring systems can efficiently complete flaring operations. They are particularly suitable for use in scenarios with stringent sealing requirements, such as R410A high-pressure refrigerant systems and hot water circulation systems, helping to improve pipe connection quality and system lifespan.

-

A copper tube bender is a specialized tool for forming copper tubes. It bends co...

-

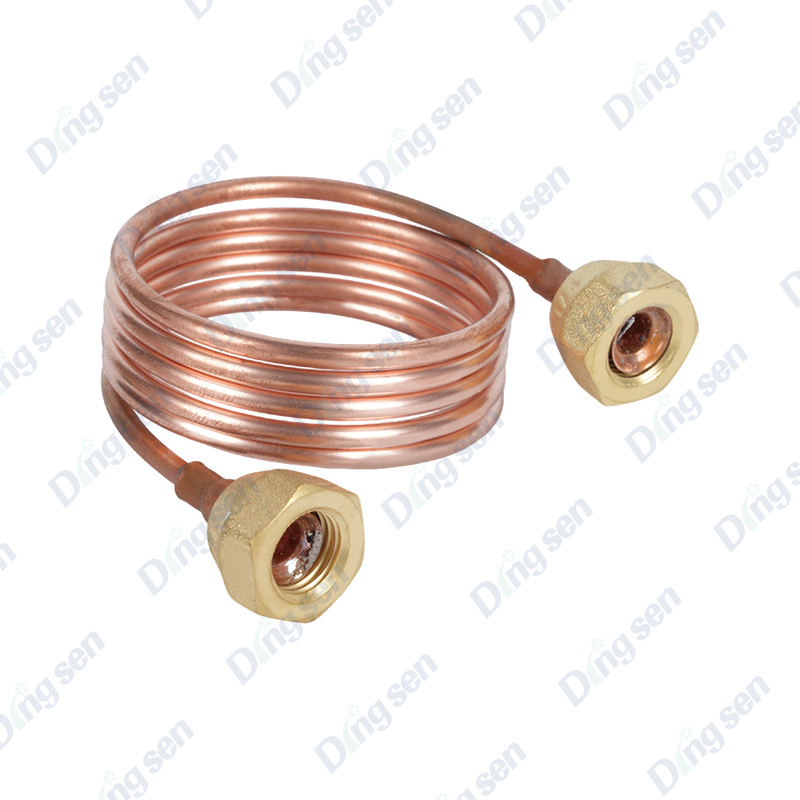

Copper capillary tube assemblies are core throttling components in refrigeration...

-

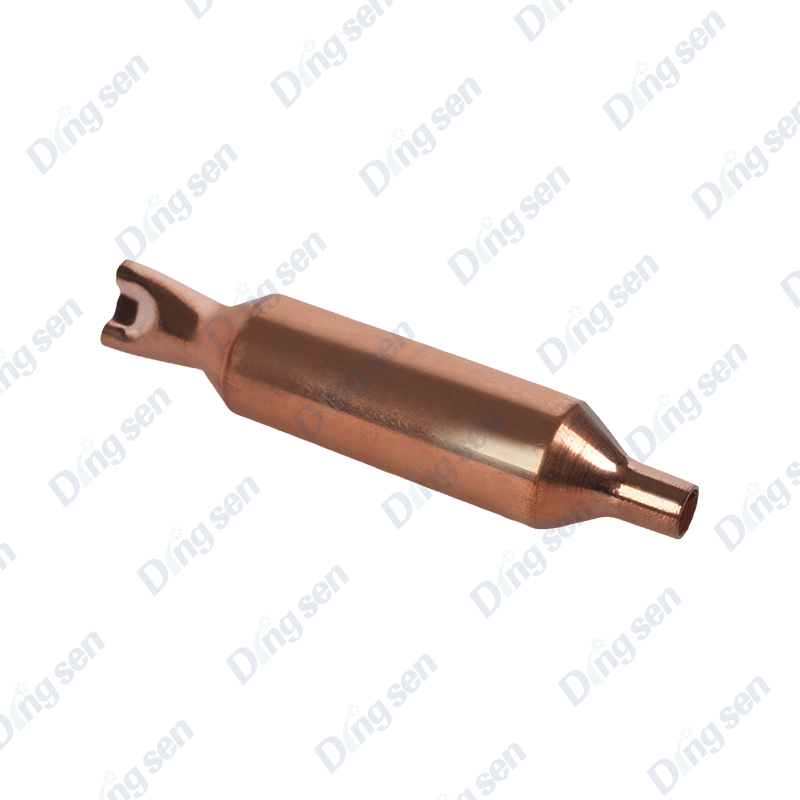

The copper drying filter is a specialized purification component for refrigerati...

-

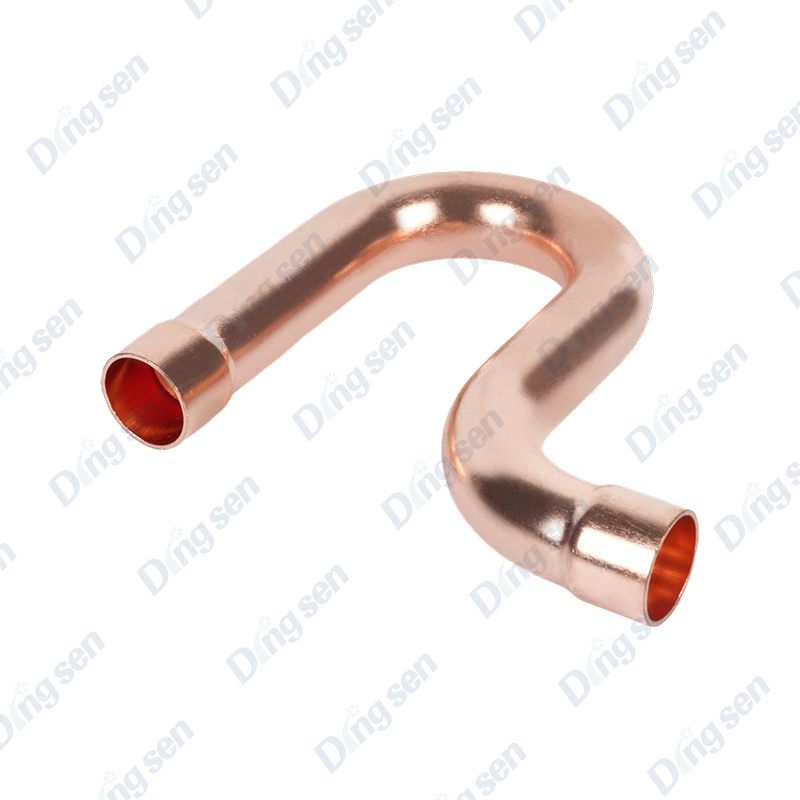

Copper pipe fittings are core connectors for air conditioning and refrigeration ...

-

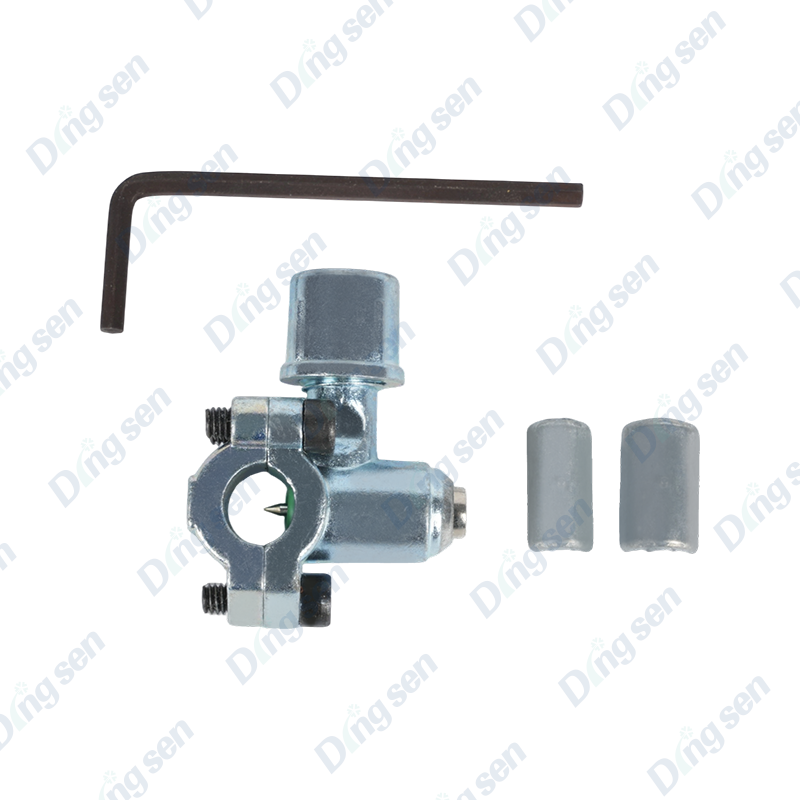

The copper pipe puncture valve is a specialized valve for copper pipe system mai...

-

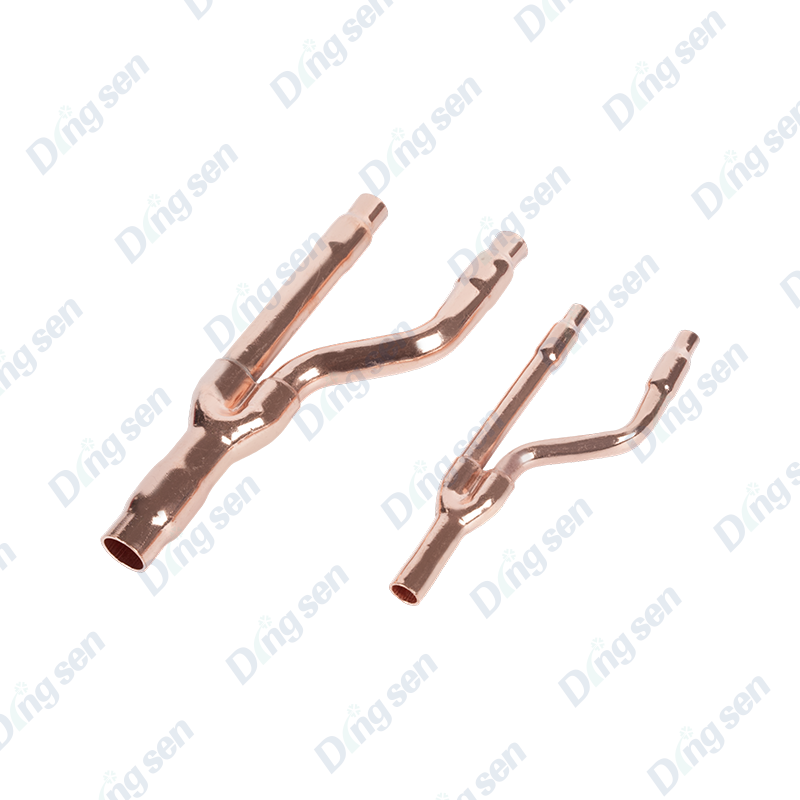

Copper Branch pipe series are core components for refrigerant distribution in re...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

The main differences between Quick Connector for Car Air Conditioning and traditional fittings lie in installation convenience, sealing reliability, and maintenance efficiency. Traditional fittings usually require threaded or flange connections, which have long installation cycles and are prone to l...

READ MORE -

Refrigeration and air conditioning system accessories effectively enhance the operational safety and stability of the entire system through multiple mechanisms, including structural protection, pressure control, electrical protection, and intelligent monitoring. From pipeline fittings and valve comp...

READ MORE

en

en  Español

Español عربى

عربى