In air conditioner installation and maintenance, the differences between thickened air conditioner nuts and ordinary nuts are very significant, mainly in terms of pressure resistance, sealing stability, and crack resistance. Ordinary nuts have thinner walls and are prone to micro-cracks under high p...

READ MORECopper pipe fittings series

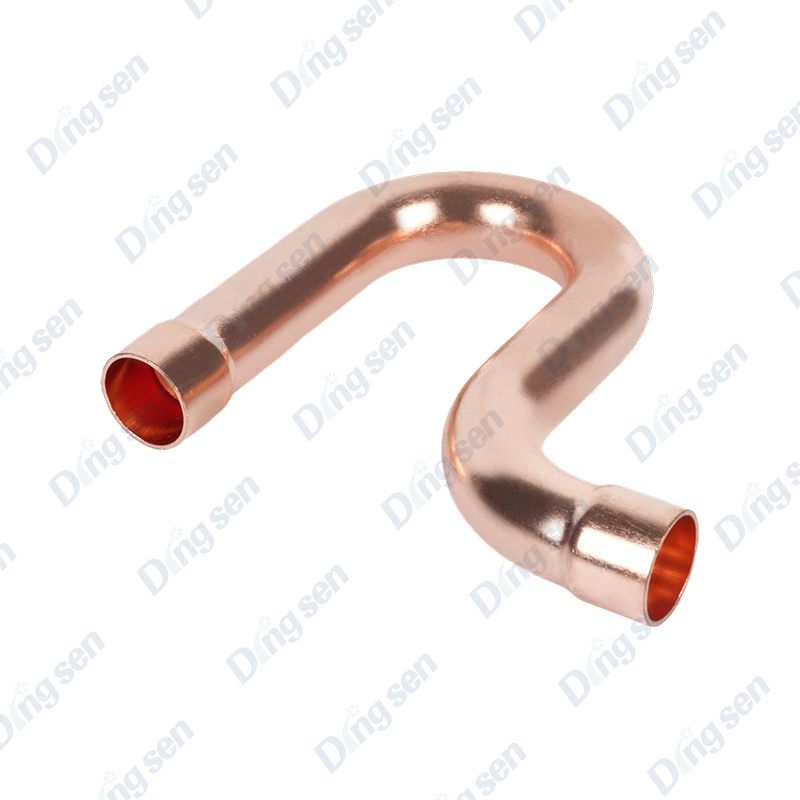

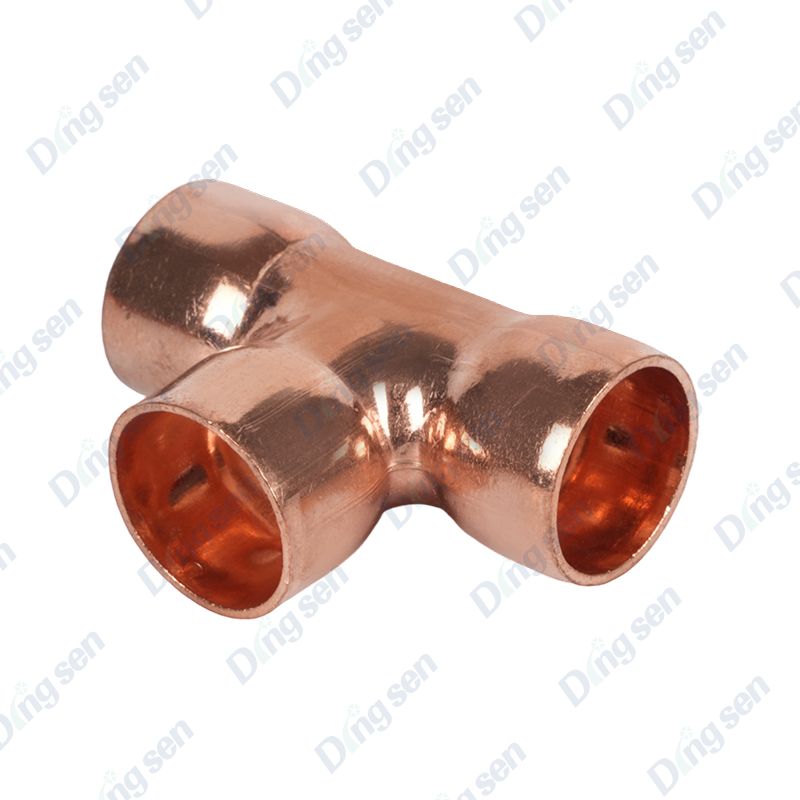

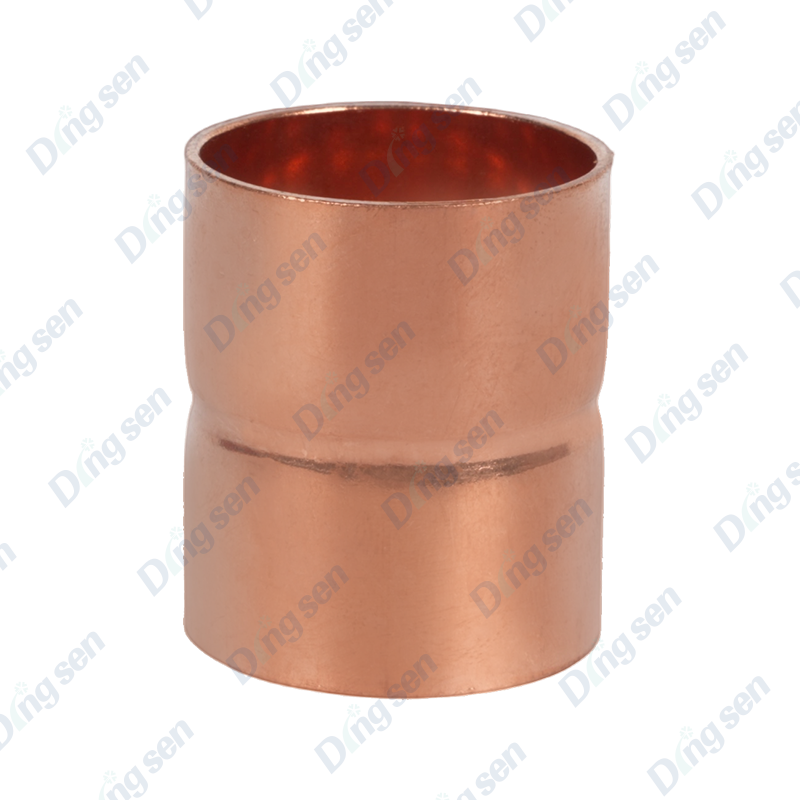

Copper pipe fittings are core connectors for air conditioning and refrigeration systems. They include joints, elbows, and tees, enabling precise connection of copper pipes, ensuring efficient refrigerant transmission and adapting to various cooling needs.

They are used for piping installation and repair in residential and commercial air conditioners, cold storage, and refrigeration equipment.

Produced with premium copper, they undergo precision tensile and pressure testing, ensuring compatibility with mainstream refrigerants and excellent sealing performance.

Our service includes selection and installation guidance. Advantages include excellent thermal conductivity, corrosion resistance, ease of processing, and stable operation.

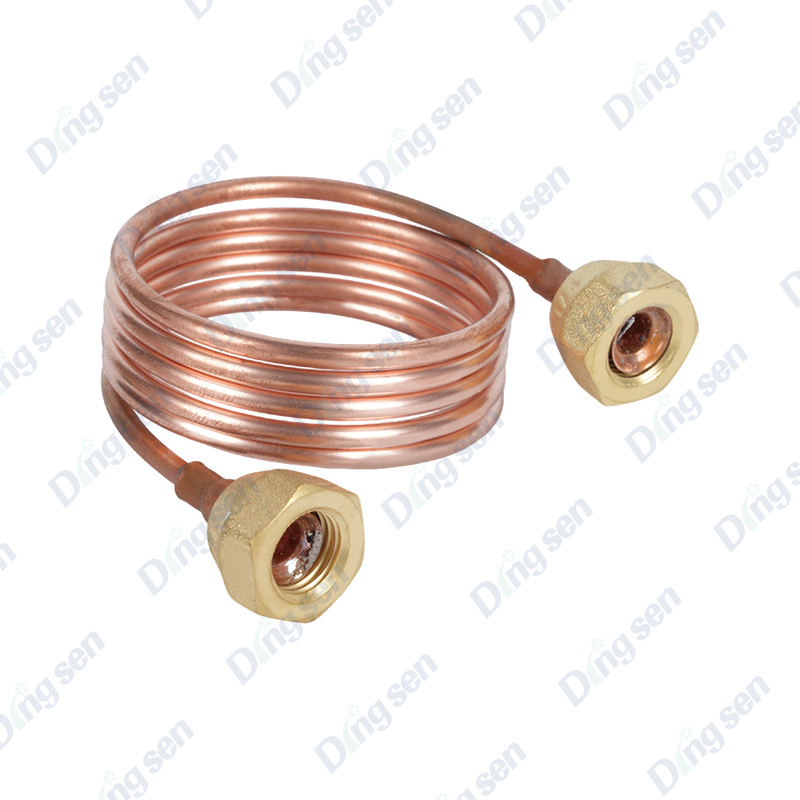

Copper pipe fittings are core connectors for air conditioning, refrigeration, and fluid transport systems. They come in a variety of sizes, including connectors, elbows, tees, and caps. Their core advantages are "high adaptability and long-lasting, reliable connections." Crafted from copper through precision drawing and extrusion (some complex fittings utilize forging), they achieve an inner wall smoothness of Ra0.8μm, reducing refrigerant transmission resistance. Copper's high thermal conductivity helps balance pipe temperatures, making it compatible with mainstream refrigerants such as R22, R410A, and R32. They withstand extreme temperatures of -200°C to 250°C and remain corrosion-free for long-term use. Key selling points address connectivity needs: The fittings utilize precision turning or flaring at the joints; some elbows and tees feature streamlined interiors to minimize pressure loss caused by refrigerant turbulence; custom sizes (6mm to 54mm diameter) are available to accommodate diverse system designs; and the material's ductility allows for easy bending and processing, making it suitable for complex piping layouts. Applications include household air conditioners (wall-mounted/cabinet unit connection pipes), commercial central air conditioners (multi-split/ducted unit pipes), industrial cold storage (food cold chain/pharmaceutical refrigeration pipes), commercial freezers (display cabinets/freezers), and specialty refrigeration equipment (laboratory cryogenic chambers/industrial chillers). Whether pre-installing pipes for new unit production, setting up systems during engineering installation, or repairing and replacing older equipment, the stable connection ensures efficient refrigerant transmission, reduces the risk of cooling efficiency loss or leakage caused by pipe problems, and adapts to the fluid connection needs of different scenarios.

-

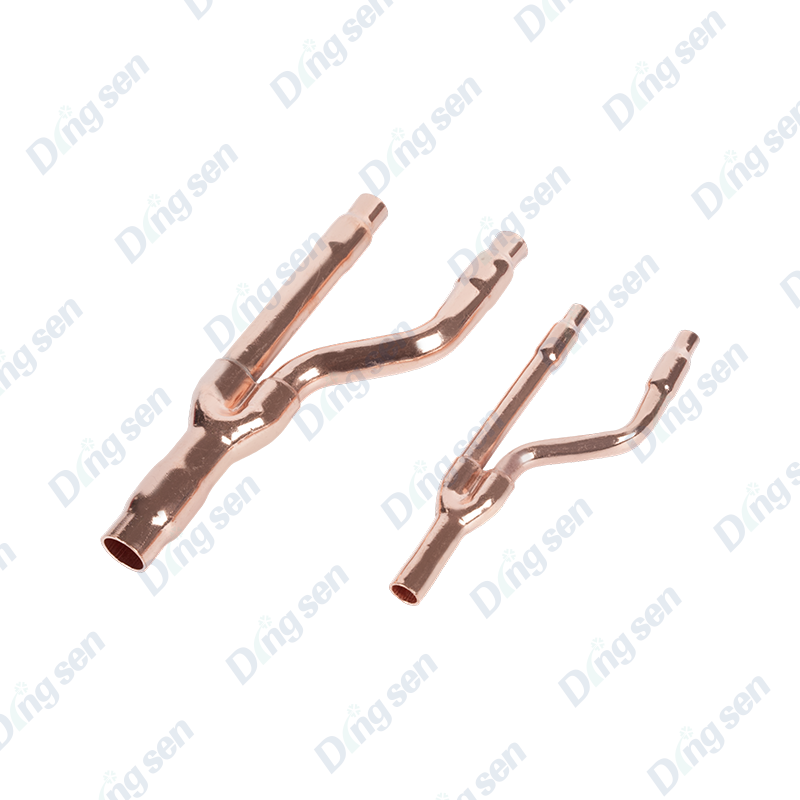

Copper Branch pipe series are core components for refrigerant distribution in re...

-

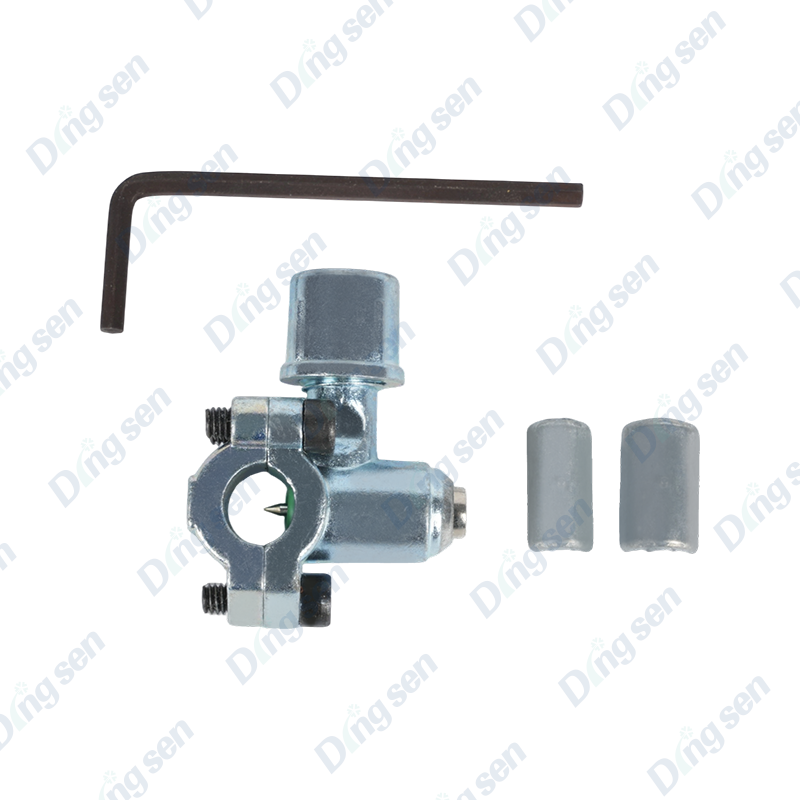

The copper pipe puncture valve is a specialized valve for copper pipe system mai...

-

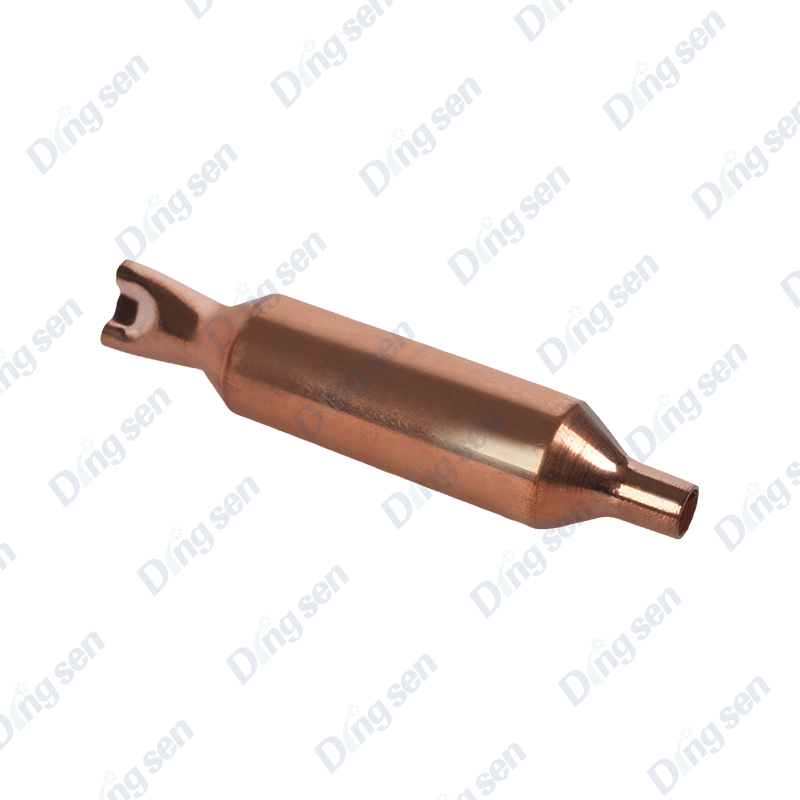

The copper drying filter is a specialized purification component for refrigerati...

-

The copper tube expander is a specialized tool for copper tube connection. It ex...

-

Copper capillary tube assemblies are core throttling components in refrigeration...

-

A copper tube bender is a specialized tool for forming copper tubes. It bends co...

About DingSen

- Dingsen: Refrigeration & auto AC parts since 2008.

- Decades of precision manufacturing.

- Durable evaporators, condensers, connectors.

shaoxing DingSen Refrigeration Technology Co Ltd.

-

-

A cylinder valve, as a key pneumatic control component, operates on the principle of compressed air power conversion. Simply put, a cylinder valve controls the inflow and outflow of compressed air to drive the linear or rotary motion of a piston within the cylinder, thereby automating the operation ...

READ MORE -

Charging air conditioner refrigerant using a Fluorine filling hose involves four core steps: First, connect the Fluorine filling hose to the pressure gauge manifold and the refrigerant cylinder; second, purge the air from the hose (evacuate the system); next, tightly connect the other end of the Flu...

READ MORE

en

en  Español

Español عربى

عربى